Paper egg tray dryer | egg tray drying machine

| machine function | drying |

| product | paper egg tray |

| work efficiency | 30 minutes |

| mold | SL-4*4 |

| output | 3500pc/h |

| paper consumption | 280kg/h |

| water consumption | 560kg/h |

| energy used | 78kg/h |

| worker number | 4-5 |

You can now ask our project managers for technical details

The paper egg tray dryer is an essential device for dehydrating the egg tray after it is formed. Since the egg tray is made by pulping, the egg tray will contain a lot of water after it is created. Therefore, an egg tray drying machine is required for dehydration. Our egg tray drying equipment can dry a batch of egg trays in 30 minutes. The metal egg tray dryer also has a certain impact on the quality of the egg tray.

Advantages of paper egg tray dryer

- 30% less fuel than a brick house.

- The temperature is controllable to ensure the quality of the egg trays in the dryer, and the egg trays. are gelatinized because they are too high.

- The multi-layer egg tray machine occupies a small area and saves space.

- The paper egg tray dryer is fully automatic production, saving workers.

Egg tray dryer parameters

| mold | output | paper consumption | water consumption | energy used | worker number |

| SL-4*4 | 3500pcs/h | 280kg/h | 560kg/h | 78kg/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kg/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kg/h | 3-4 |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kg/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kg/h | 3-4 |

At Shuliy Egg Tray Machinery, we have the above 5 hot-selling egg tray dryer machines for sale. The output of these five models of machines is 3500pcs/h, 4000pcs/h, 5000pcs/h, and 8000pcs/h. You can choose the right drying equipment according to the size of your egg tray production plant.

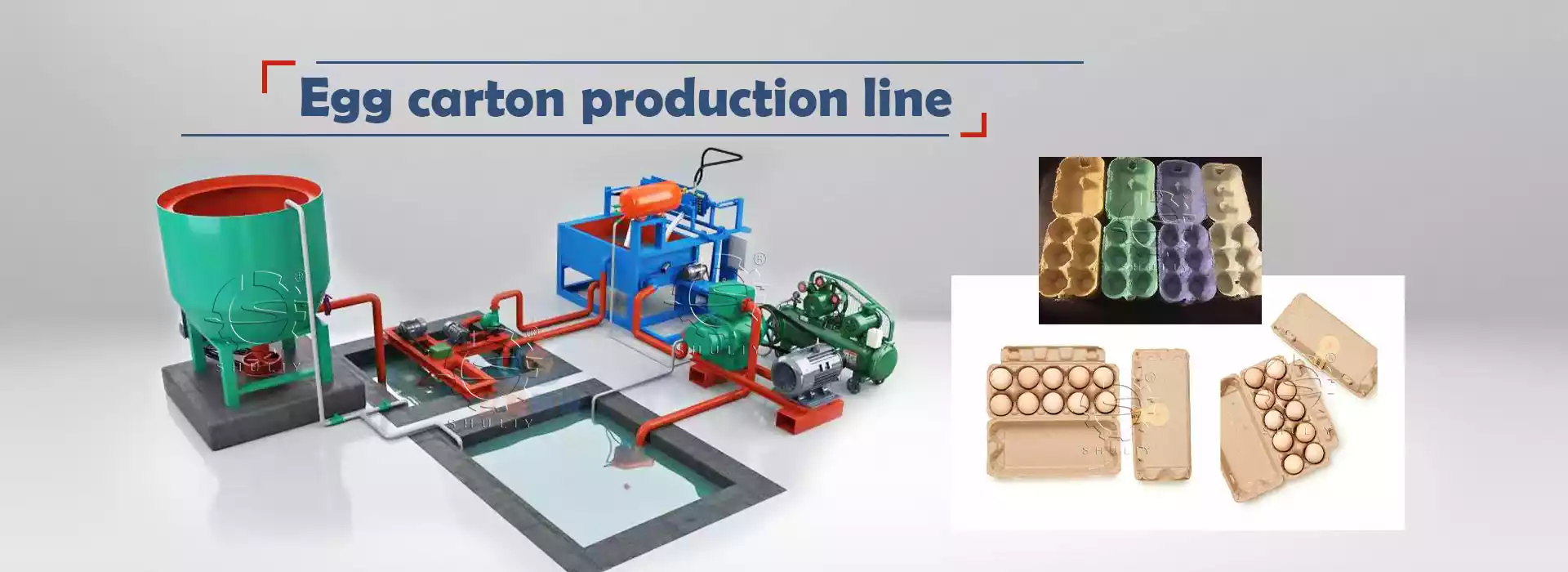

Introduction of egg tray drying method

Egg tray drying machine

The egg tray drying machine is suitable for the egg tray production line with large output. The egg tray dryer takes about 30 minutes to dry a batch of egg trays, and the efficiency is relatively high. In addition, the metal dryer can save 30% compared with the brick kiln dryer. fuel.

Natural drying

Natural drying is the simplest drying method for egg tray drying. Generally, if the output is 1000-2000pcs/h, natural drying can be used. When the temperature reaches 30-40 degrees Celsius, it can be dried in one day.

Brick kiln drying

When drying the brick kiln, build a brick kiln for drying. The efficiency of brick kiln drying is greater than that of natural drying. The site area of brick kiln drying is 30 square meters, and the working efficiency of brick kiln drying is relatively high, which is suitable for medium-sized production.

The heat source for the paper egg tray dryer

The egg tray drying machine can use natural gas, diesel, gasoline, biomass pellets, or heat transfer oil as the heat source, and the heating temperature is 180-220°C. Using the fan to extract the evaporated water from the product, the egg tray can be quickly dried.

It is very important to be able to control the temperature in the paper egg tray dryer. Since the egg tray is a paper product, if the internal temperature of the machine is too high, it is easy to ignite the egg tray, and if it is too low, the drying efficiency of the egg tray will be reduced.

Single-layer egg carton dryer or multi-layer egg carton dryer

There are two kinds of egg tray drying machines, single-layer egg tray dryer machines, and multi-layer egg carton drying machines. The working efficiency of single-layer machines and multi-layer machines is the same. The area of the single layer drying machine is 40 meters, and the area usage of the multi layer dryer machine is 15 meters, which is very important for customers with smaller plant areas.

In addition, the multi-layer paper egg tray dryer has a larger capacity, which is suitable for medium and large-scale egg tray manufacturing. If you have a large egg tray manufacturing plant, I recommend you choose this multi-layer dryer.