What Ingredients Can Be Used to Make an Egg Tray?

Egg trays are an essential part of the egg production and distribution process. They provide protection, convenience, and sustainability when it comes to handling eggs. One of the most commonly used materials for making egg carton is paper pulp. In this article, we will explore the ingredients required to produce paper pulp egg trays and the crucial role played by egg tray making machines in this process.

The Basics of Paper Pulp Egg Trays

Paper pulp egg trays are environmentally friendly, biodegradable, and sturdy, making them an ideal choice for storing and transporting eggs. They are made from a mixture of recycled paper and water, with some additional ingredients to enhance their properties. Here are the primary ingredients used in making paper pulp egg carton:

Recycled Paper: The core ingredient in paper pulp egg carton production is recycled paper. This paper can come from various sources, such as old newspapers, cardboard, or waste paper. The recycling of paper not only reduces waste but also conserves natural resources.

Water: Water is essential to the paper pulp making process. It is used to break down the recycled paper into a pulp through a process known as pulping. The consistency of the pulp depends on the desired thickness and strength of the egg carton.

Chemical Additives (Optional): In some cases, manufacturers may add certain chemical additives to the pulp mixture. These additives can include fire retardants, anti-fungal agents, or colorants, depending on the specific requirements of the egg trays.

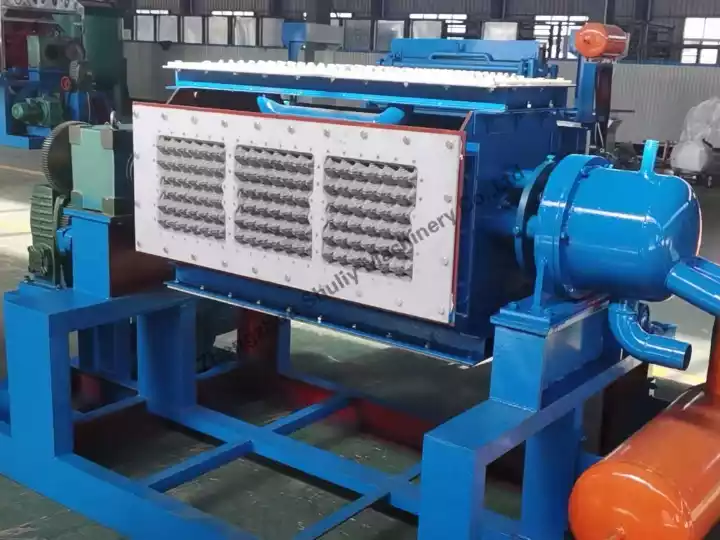

The Role of Egg Tray Making Machines

To transform the paper pulp mixture into the familiar egg carton shape, specialized machinery known as egg tray making machines are used. These egg crate manufacturing machines are designed to automate and streamline the production process, making it efficient and cost-effective.

Pulp Tray Manufacturing Process

Pulping

The first step involves placing the recycled paper into a pulper, where it is mixed with water. This process breaks down the paper fibers and creates a pulp consistency suitable for forming egg carton.

Molding

The pulp mixture is then poured into molds in the shape of egg trays. The molds can be customized to produce trays of various sizes and configurations, including those designed for chicken eggs, duck eggs, or quail eggs.

Drying

After molding, the trays are subjected to a drying process. This can be done through natural drying in the sun or using a specialized drying chamber in the egg carton making machine. Drying ensures that the trays are moisture-free and ready for use.

Trimming and Stacking

Once dried, the egg carton may undergo trimming to remove any excess material and achieve a neat finish. They are then stacked and prepared for packaging or distribution.

Benefits of Paper Pulp Egg Trays

Paper pulp egg trays offer several advantages over alternative materials such as plastic or styrofoam:

- Environmentally Friendly: Paper pulp egg trays are biodegradable and can be recycled. They have a significantly lower environmental impact compared to non-biodegradable materials.

- Sturdiness: Paper pulp egg cartons provide adequate protection for eggs during transportation. They are sturdy enough to prevent damage while being lightweight.

- Customizability: Egg tray machines can be adjusted to create trays of various shapes, sizes, and designs to meet specific market needs.

In conclusion, making paper pulp egg cartons involves utilizing recycled paper, water, and optional additives, with the aid of specialized egg tray making machines. These trays offer a sustainable and reliable solution for handling and transporting eggs, making them a preferred choice for many in the egg industry. By prioritizing eco-friendly materials and efficient production methods, we can contribute to a more sustainable and responsible approach to egg packaging and distribution.