Building an Efficient Egg Tray Manufacturing Plant

In the era of sustainable packaging solutions, the demand for eco-friendly alternatives is rapidly increasing. With the rise in popularity of egg trays as a viable option, setting up an efficient egg tray manufacturing plant has become a promising business venture for many entrepreneurs.

Market Analysis and Planning

Before delving into the process of establishing an egg tray manufacturing plant, thorough market analysis and strategic planning are crucial. Understanding the current market trends and consumer demands for sustainable packaging is paramount. It is essential to evaluate the competition and identify unique selling propositions to stand out in the market.

Infrastructure and Location

Choosing the appropriate location and ensuring the necessary infrastructure is pivotal for the smooth operation of an egg tray production line. Proximity to the source of raw materials is vital to minimize transportation costs and streamline the production process. An ideal factory layout should accommodate the egg tray making machine and other necessary equipment efficiently.

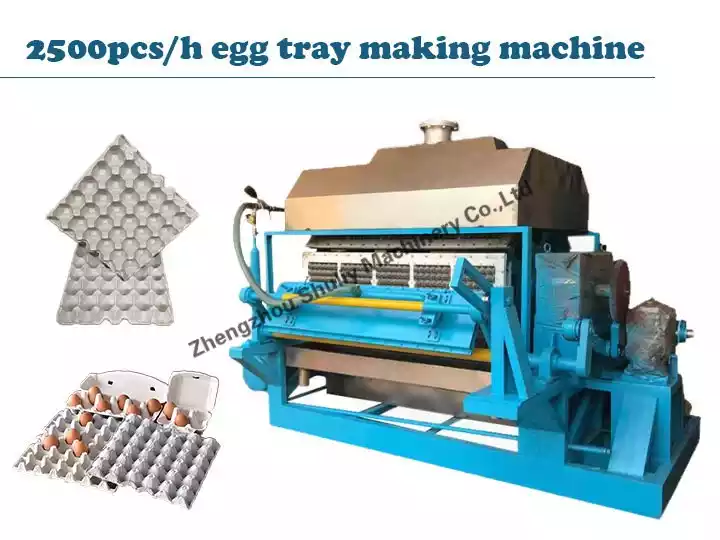

Machinery and Equipment

Investing in high-quality and modern egg carton making machines is essential for enhancing productivity and ensuring the consistent production of high-quality egg trays. Choose automated machines that can handle various production capacities, ranging from small-scale to large-scale operations. Additionally, consider auxiliary equipment such as pulping machines and drying systems to complete the egg tray manufacturing plant.

Raw Materials and Production Process

Utilizing recyclable materials in the production process aligns with eco-friendly practices and enhances the marketability of the final product. Efficiently sourcing materials such as recycled paper and other biodegradable substances not only contributes to sustainability but also reduces production costs. Implement a streamlined egg carton production process, from pulping the raw materials to molding and drying the trays, to ensure a seamless manufacturing operation.

Quality Control and Maintenance

Implementing stringent quality control measures at every stage of production is imperative to deliver durable and reliable egg trays to consumers. Regular maintenance of the machinery and equipment is crucial to prevent unexpected breakdowns and ensure continuous production. Incorporating regular quality checks ensures that the produced egg trays meet the required standards and adhere to industry regulations.

Compliance and Environmental Sustainability

Adhering to industry regulations and environmental standards is non-negotiable in the manufacturing process. Ensure compliance with safety protocols and waste management regulations to minimize environmental impact. Employing energy-efficient practices and utilizing renewable energy sources can further enhance the environmental sustainability of the egg tray manufacturing plant.

Establishing an efficient egg tray production plant demands meticulous planning, the integration of advanced technology, and a commitment to environmental sustainability. By following the outlined steps and leveraging high-quality machinery, your egg tray production plant can become a frontrunner in providing eco-friendly and reliable packaging solutions in the market.