Egg tray pulper | paper shredder machine

| Model | SL-1.0 |

| Power(kW) | 7.5 |

| Volume(m³) | 1.2 |

| Size(mm) | 1400*1200*1400 |

| Capacity(kg/once) | 300 |

| SL-2.0 | 11 |

| Volume(m³) | 2.0 |

| Size(mm) | 1550*1500*1400 |

| Capacity(kg/once) | 400 |

| SL-4.5 | 22 |

| Volume(m³) | 4.5 |

| Size(mm) | 2200*2200*2600 |

| Capacity(kg/once) | 600 |

You can now ask our project managers for technical details

The egg tray pulper, also known as a paper shredder machine, is a device used to crush and make pulp from waste. During the processing of egg trays, the paper first needs to be made into pulp, and then the egg trays are made by a forming machine. The Egg tray pulping machine is a necessary machine for egg tray production and the basis for egg tray production. The pulping machine can also be used for the forming of various shapes of paper products in tableware manufacturing plants, papermaking industries, and wine bottle holders.

The raw material of the egg tray pulper

The raw materials of the pulper are mainly paper products, such as corrugated boxes, waste books, and A4 paper, which can be used for egg tray production. The pulper can use these waste paper products for recycling and crushing into pulp, which is worth mentioning. Yes, in the process of pulping, there is no need for paper crushing, and it can be directly processed by a hydraulic pulper.

What are the ingredients of the egg tray pulper?

The main component of the egg tray machine is pulp, but in order to make the egg tray more firm, it is generally necessary to add certain additives to the egg tray. You can add some stone powder to the pulp to ensure that the egg tray is shaped enough. In addition, you need to add some glue to ensure that the pulp is sticky. Of course, this needs to be added in proportion. Need to experiment several times during production to find the best ratio to add.

The effect of pulping on the quality of egg trays

Pulping is the first step in the production of egg trays, and the impact of pulping on egg trays is very important, such as the ratio of water and paper, and the color adjustment of egg trays are all done in this step of pulping. In addition, the higher the smoothness of the pulp, the more beautiful the egg tray produced. Therefore, in pulping, high-quality egg tray pulper and raw materials are selected.

How to make egg tray pulp?

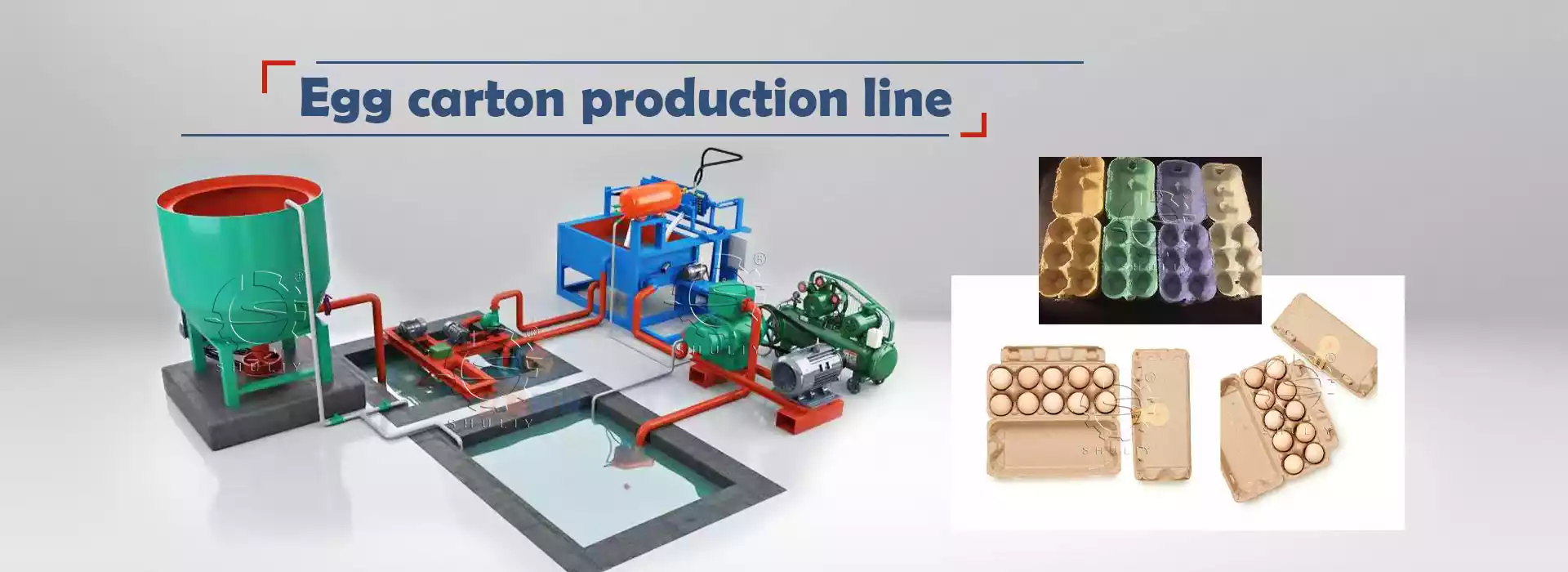

Egg tray pulping requires an egg tray pulping machine and three pools, the first pool is used to hold the pulp, the second pool is used to adjust the ratio of pulp and water, and the third pool is a water storage tank. After processing in three pools, the pulp raw material that meets the egg tray forming machine is produced, then the egg tray is formed, and finally, it is egg tray dried. The water produced by the egg tray can be recycled, which is conducive to saving water.

Paper shredder machine parameters

| Model | Power(kW) | Volume(m³) | Size(mm) | Capacity(kg/once) |

| SL-1.0 | 7.5 | 1.2 | 1400*1200*1400 | 300 |

| SL-2.0 | 11 | 2.0 | 1550*1500*1400 | 400 |

| SL-4.5 | 22 | 4.5 | 2200*2200*2600 | 600 |

What parts are included in the pulper?

Egg tray pulp consists of three parts, which are hydraulic pulper, pulp refiner, and pulp pump, which can not only achieve the function of paper crushing but also pulp grinding to ensure the smoothness of pulp. Mix well with water to ensure that the thickness of the egg tray is even. Pulping is the basic work of making egg trays. After pulping, it is then shaped and dried. We can provide a full set of egg tray production lines, and can also produce egg box production lines or another packaging machine for other fragile items.