Apple tray making machine | paper fruit tray machine

| model | SL-3*4 |

| product | apple tray |

| capacity | 2000-2500pcs/h |

| paper consumption | 200kg/h |

| Water Consumption | 450kg/h |

| energy used | 58kw/h |

| worker | 4-5 |

You can now ask our project managers for technical details

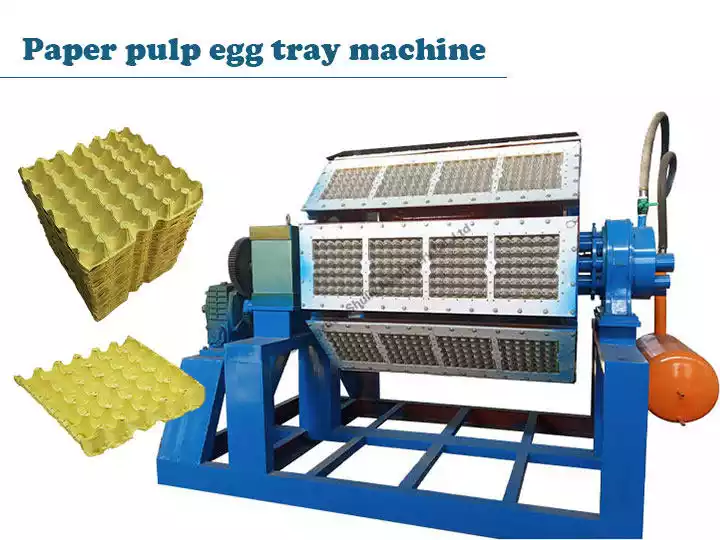

The apple tray making machine is a machine used to produce a fruit packing tray, and can also produce other fruit trays, such as kiwi fruit, persimmons, and other fruits that are easily crushed.

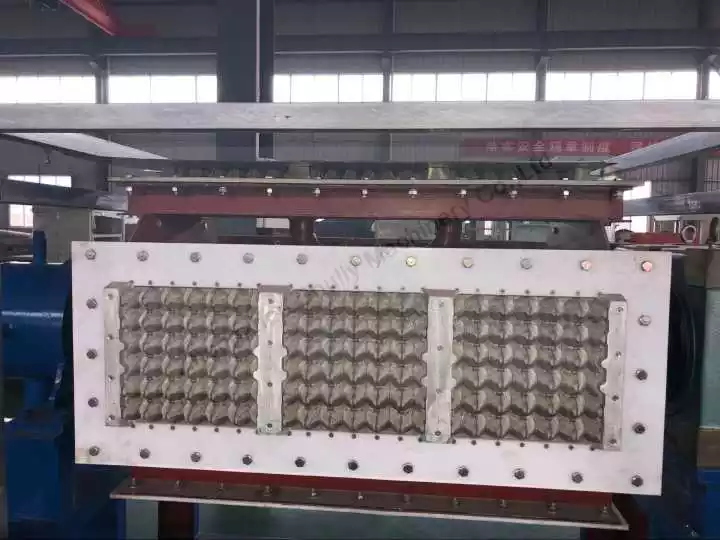

The apple tray machine can make paper trays of different sizes by replacing different molds. Since the apple trays are made of waste paper products, the packaging materials are environmentally friendly products. It will not pollute the environment during the production process.

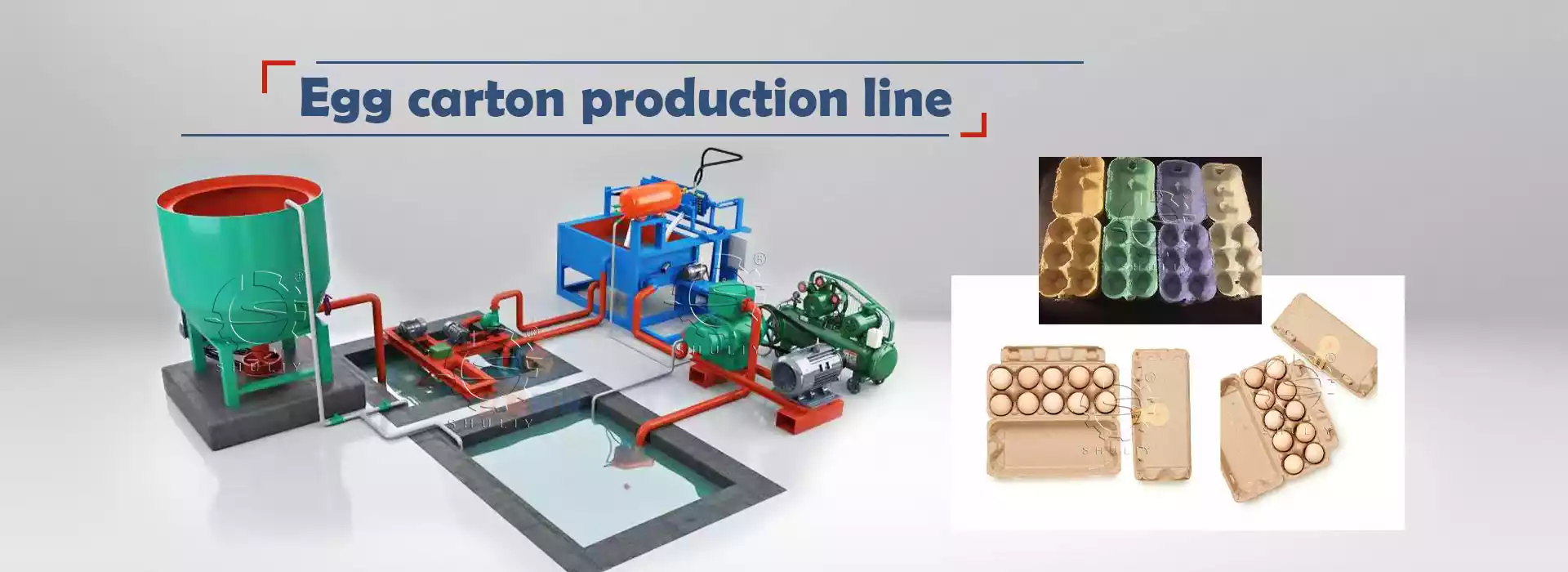

Apple tray processing process

Apple trays need to use waste paper as a raw material for a production called processing, which can be paper products such as cartons, books, newspapers, etc. The process of apple tray processing is pulping first, then apple tray molding, and finally drying and packaging. Since the raw material of the apple tray is paper, it is a degradable packaging material. very environmentally friendly

Apple holder parameters

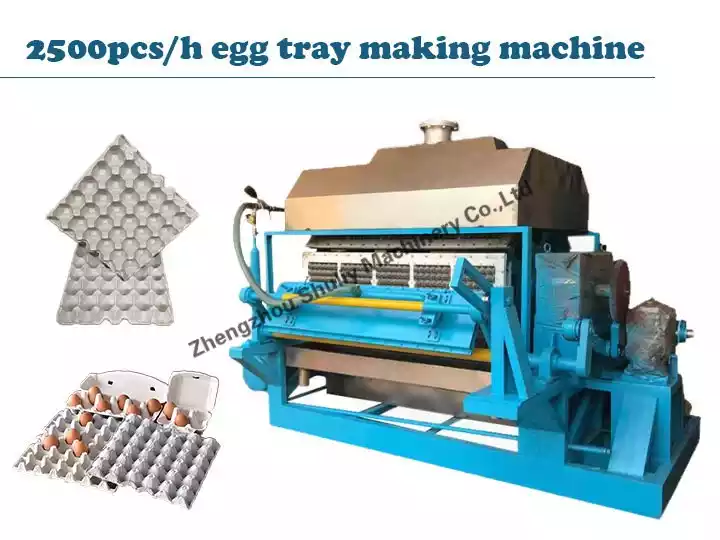

There are many models of apple trays from Shuliy company, ranging from 1000pc/h-8000pc/h, the smallest model is 1000pc/h, also called SL-3*1, the machine has one axis, and there are three small apple trays on one axis model so that 3 apple trays can be produced per processing.

| model | capacity | paper consumption | Water Consumption | energy used | worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kw/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kw/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kw/h | 3-4 |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kw/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

Why use an apple tray?

There are many areas where fruits are exported or need to be transported long-distance. If there is no protection on apple trays, the fruits may collide with each other, which will cause the apples to be extremely perishable. Therefore, fruits that need to be transported over long distances will be placed in the fruit tray for protection.

The apple tray making machine is designed and manufactured according to the geometric shape, specifications, and protection requirements of the product to be packaged. It has ideal protection effects such as buffering, shock resistance, compression resistance, impact resistance, anti-static, anti-corrosion, moisture-proof, etc.

It is widely used in glassware, ceramics, electronic appliances, mechanical parts, instruments, tools, toys, mobile phones, and other products on the lining packaging, with the improvement of technology and production technology, paper trays are also slowly used in outer packaging of products, directly packaging the product.

Which fruit trays can be processed?

Many fruits do not hurt that squeeze and need good packaging, this fruit tray-making machine can not only process apple trays but also trays of grapes, persimmons, kiwi, pears, and other fruits because our apple tray making machine molds can be customized, the corresponding mold can be made according to the customer’s fruit shape. Therefore, paper tray production machines are widely used.

It’s important to note that, our egg carton making machine can only make paper egg trays.

Features of the apple tray making machine

- The apple tray making machine model is an integrated machine. It can perform the functions of retrograde suction, forming and placing apple trays.

- It adopts a PLC control system. During the forming process of apple trays, the pulping will first be adsorbed on the machine, and then it will be formed.

- The excess water in the apple tray will be squeezed out, and the apple tray making machine will demold the formed apple tray. The whole process of Apple tray processing is fully automatic.

Export to Turkey paper fruit tray machine

We exported an apple tray production line to Turkey. The customer is a company. It mainly sells fruit trays after production to fruit export companies. Fruits need to be packaged before export. The customer purchased three kinds of molds, one an egg tray mold, one an apple tray mold, and the other a grape tray. Grapes need better protection during transportation.