Can I order a custom egg tray machine from Shuliy?

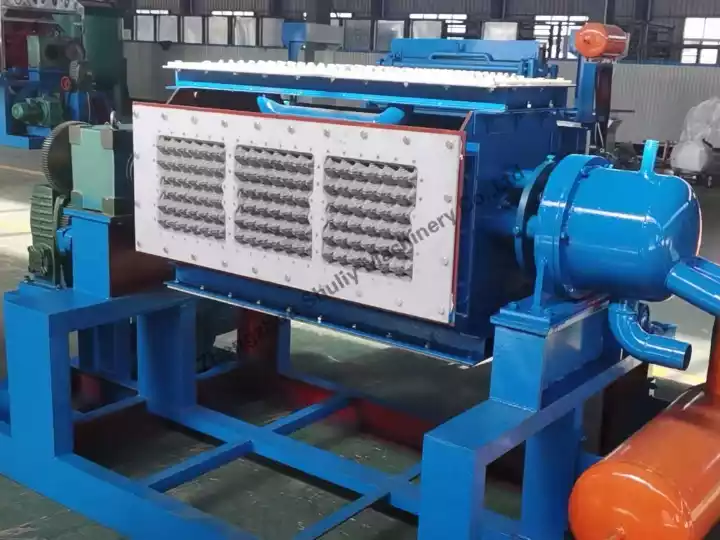

With so many models of egg tray machines available, can these standardized machines truly match 100% of customers’ unique business needs?

Shuliy gives you a clear and exciting answer: yes, you can absolutely produce your own custom egg tray machine at Shuliy!

Customized production capacity

This is the most fundamental and crucial customization option. Your business scale determines the machine size you require.

- Small-scale machines (1000-2500 sheets/hour): low investment, minimal footprint, and quick return on investment.

- Medium-scale machines (3000-5000 sheets/hour): the most popular models on the market, offering an ideal balance between production capacity and investment.

- Large-scale machines (6,000–8,000 pieces/hour and above): suitable for large paper mills or regional egg tray suppliers, capable of meeting massive market demands.

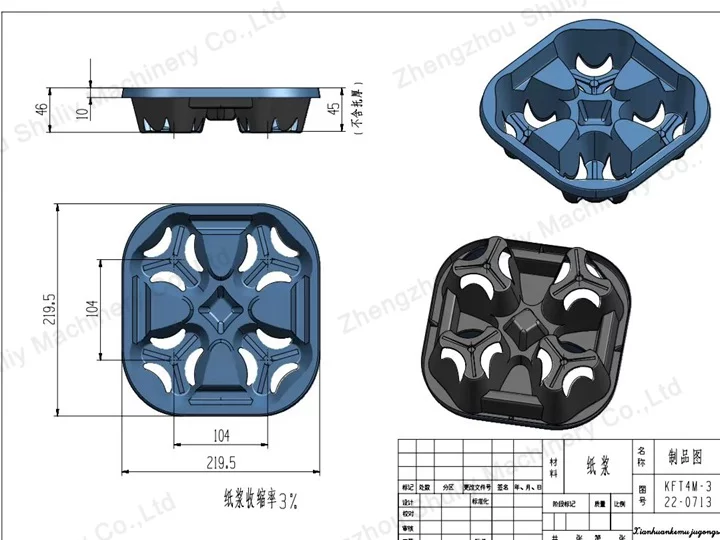

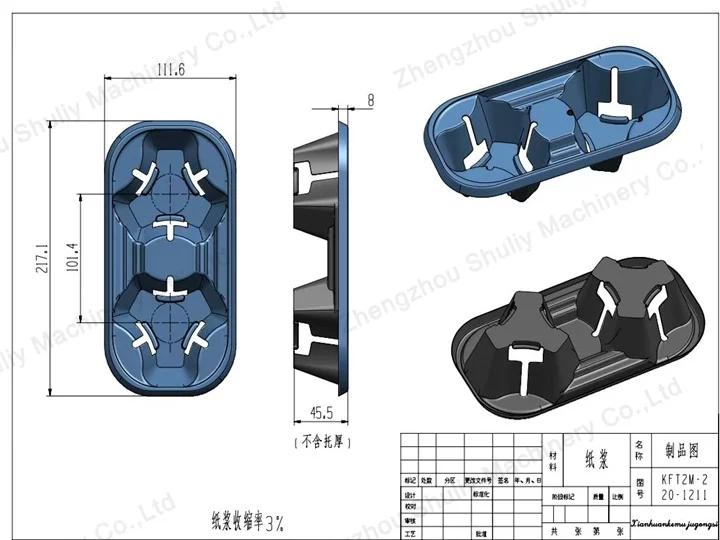

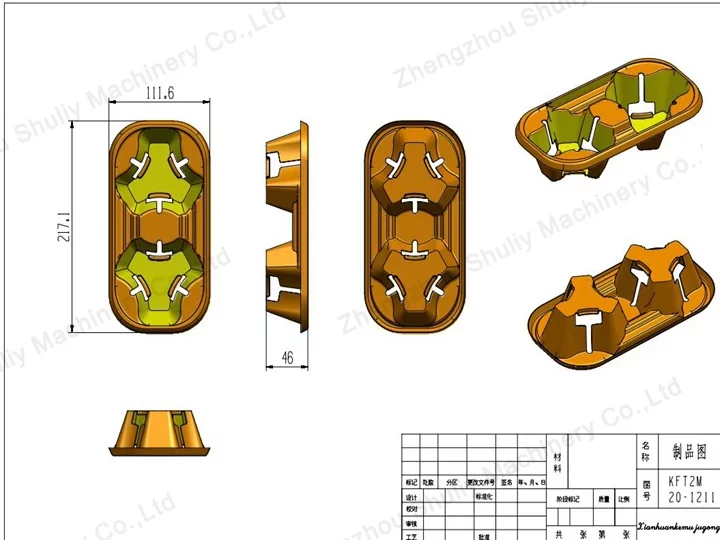

Custom mold manufacturing

Who says egg tray machines can only produce egg cartons? By customizing different molds, your machine transforms into a versatile production center.

Egg trays or cartons: 4-cell, 6-cell, 10-cell, 12-cell, 15-cell, 30-cell… We can customize any specification of egg tray or carton for you.

Fruit trays: apple trays, pear trays, mango trays, and more—providing perfect protection for delicate fruits.

Cup holders or coffee trays: 2-cup holders, 4-cup holders—essential for coffee shops and takeout businesses.

Industrial packaging: cushioning inserts for electronics, home appliances, and bottled wine.

Medical supplies: such as disposable bedpans, urinals, and more.

Custom drying solutions

Drying is the most energy-intensive stage in egg tray production. Selecting the drying method best suited to your local conditions can yield significant operational cost savings.

Sun-drying:

Suitable regions: areas with abundant sunlight, hot and dry climates, and low land and labor costs.

Advantages: Zero energy consumption, lowest initial investment.

Brick kiln drying line:

Suitable regions: customers with moderate land costs seeking efficiency improvements on a limited budget.

Advantages: utilizes multiple fuels (coal, wood, natural gas) for high cost-effectiveness. Requires the customer to construct the drying kiln structure.

Metal drying line and egg tray drying room:

Suitable regions: areas with limited land space, high automation requirements, and stringent environmental standards.

Advantages: compact footprint, rapid installation, high thermal efficiency, and the highest automation level. Supports multi-tiered design to maximize vertical space utilization.

Customizable automation levels

Based on your budget and local labor costs, you can select equipment with varying degrees of automation.

Manual or semi-automatic: suitable for small-scale equipment, requiring manual assistance for certain processes, with the lowest investment cost.

Fully automatic: the entire egg tray production line operates automatically—from pulping, forming, and drying to stacking, counting, and packaging—minimizing reliance on manual labor and ensuring production efficiency.

Your success begins with the right custom egg tray machine

A standardized machine may get the job done, but a machine tailored specifically for you becomes the true powerhouse driving your business growth. It perfectly aligns with your facility, budget, market, and development goals.

We take pride in offering such flexible customization services. Our goal is to provide you with a solution that isn’t just “functional”—it’s the “best fit” for your needs.

Ready to build an egg tray production line that’s truly yours? Contact our customization experts today, share your vision, and let’s turn your business blueprint into reality!