7 Essential Steps to Starting an Egg Tray Factory

With the continuous growth in egg consumption, eco-friendly biodegradable egg cartons are gradually replacing plastic packaging to become the mainstream choice for global egg transportation.

Egg carton machines utilize waste paper as raw material, offering low investment, high profits, and significant environmental benefits, making them a popular project among emerging investors.

So, how does one establish an egg tray factory from scratch?

Step 1: assess local waste paper resources

The primary raw materials for egg cartons include waste cardboard boxes, discarded books, newspapers, paper trimmings, and similar waste paper.

Before establishing the factory, investigate local waste paper collection channels, such as:

- Waste paper supply from paper mills

- Recycling centers

- Paper trimmings from printing plants

- Local waste sorting centers

The stability of raw material supply and the feasibility of transportation distances are critical factors for the project’s long-term profitability.

Step 2: selecting an appropriate factory site

The factory site selection should meet the following criteria:

- Proximity to raw materials and water sources (the pulping process consumes significant amounts of water)

- Convenient transportation access (facilitates finished product shipping)

- Distance from residential areas (beneficial for environmental approvals and noise control)

Spacious premises: a total area of no less than 1,500 square meters is recommended, encompassing pulping, forming, drying, storage, and office zones.

Step 3: determine equipment configuration and production line type

Based on investment budget and production scale, common egg tray production lines are categorized as follows:

| Type | Suitable scale | Features |

|---|---|---|

| Semi-automatic production line | Small factories | Low investment for initial trial production |

| Fully automatic production line | Medium to large factories | High automation, stable output |

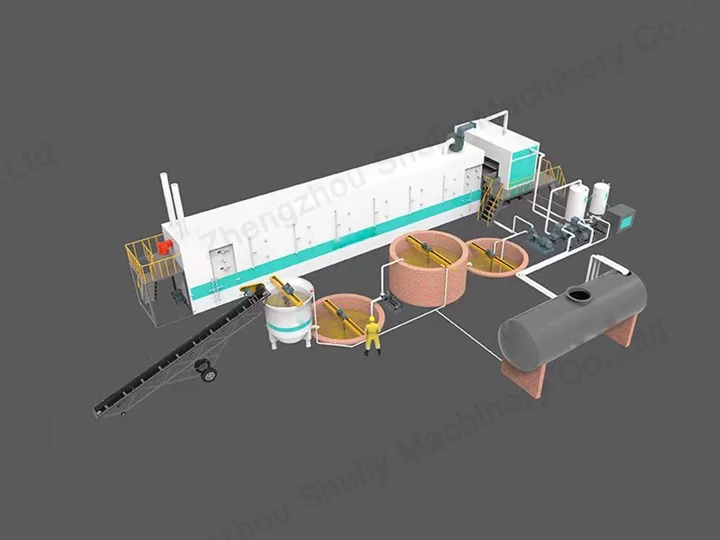

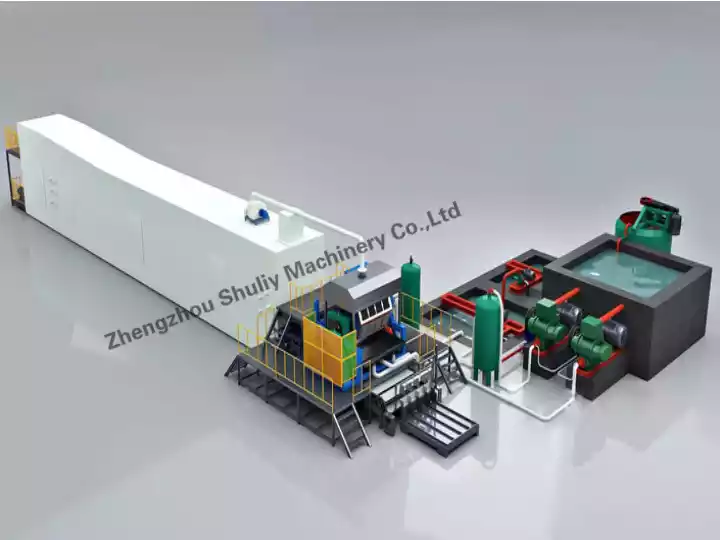

Production lines primarily include: pulper, egg tray forming machine, egg carton dryer, egg tray hot press, and packaging machine

Step 4: planning the egg tray factory production process

The entire egg tray production process is as follows:

Waste paper pulping → Molding → Drying → Hot pressing and shaping → Packaging and warehousing

The automated production line requires only 1–2 operators to run. It is energy-efficient and environmentally friendly throughout the process, featuring automatic temperature control and automatic pulp feeding, significantly reducing labor costs.

Step 5: ensure environmental and safety approvals

Before establishing the factory, familiarize yourself with local environmental regulations:

- Establish a wastewater recycling system to ensure pollution-free discharge

- Select energy-efficient fuel drying systems

- Conduct noise and flue gas emission tests

- Obtain legal production and environmental permits

Compliant operations not only reduce risks but also enhance corporate brand image.

Step 6: establish stable sales channels

Common egg tray sales clients include:

- Poultry farms and egg packaging plants

- Egg wholesale markets and food companies

- Supermarkets and agricultural product chain stores

- Export markets (Middle East, Africa, Southeast Asia)

Step 7: calculate the payback period

Using Shuliy’s 4000pcs/h egg tray production line as an example:

Initial equipment investment: approximately $60,000–$80,000

Daily egg tray output: approximately 30,000–40,000 units

At market prices of $0.04–$0.06 per tray, daily revenue is approximately $1,200–$2,400

With a net profit margin of 35%–45%, the payback period is 6–10 months

Summary

Starting an egg tray factory not only positions you as a participant in environmental conservation but also as a beneficiary of a sustainable economy.

By choosing an automated egg tray production line, you gain:

- Cost control

- Simplified operation

- Rapid return on investment

- Broad market prospects

Now is the prime time to enter the molded pulp industry. Contact our expert team today for a customized egg tray production solution tailored to your needs!