Egg Carton Production Line | Egg Carton Machine

| Product | Egg carton |

| Model | SL-6*12 |

| Capacity | 8000pcs/h |

| Energy used | 100kw |

| Worker | 4-5 |

| Equipment list | pulper, egg tray forming machine, dryer, baler |

| Paper consumption | 640kg/h |

| Water consumption | 1040kg/h |

You can now ask our project managers for technical details

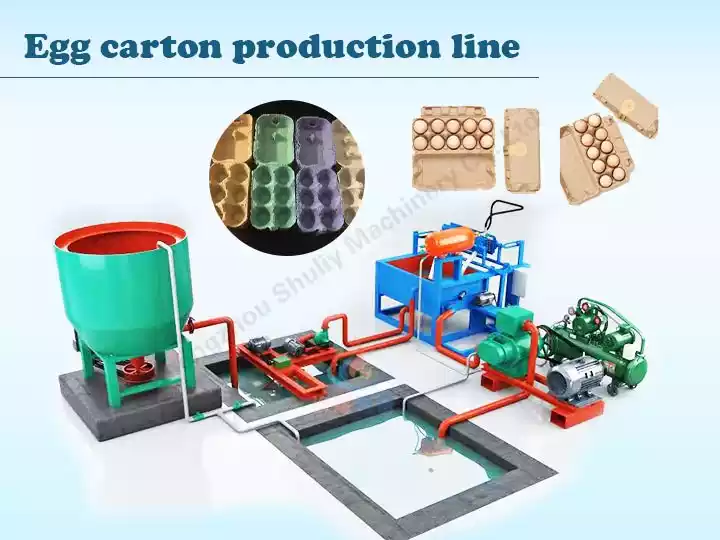

Shuliy egg carton production line provides a one-stop solution for everything from pulp molding to drying and packaging. It can ensure the production of high-quality egg cartons.

The capacity of 1,000-8,000pcs per hour can meet most of the egg carton production demands. Therefore, whether you are a small to medium-sized business or a large farm, our egg carton manufacturing line can meet your needs.

Paper egg carton production is processed by using waste paper. After simple processing, egg carton products can be obtained. There are two kinds of egg trays and egg boxes usually used for packaging eggs. Egg boxes are more sturdy when used for egg packaging, and have functions such as preservation and odor when placed inside the refrigerator. So egg boxes are often used in supermarkets and egg processing plants.

Raw materials for egg carton production line

Egg carton production can use corrugated cardboard boxes, waste quality, waste books, and other paper products to make egg cartons. It mainly uses recycled paper resources, crushing and pulping, and then egg cartons forming machines to form egg boxes.

In addition to waste paper, water, adhesives, and antimicrobial agents are essential. Adhesives add strength to paper egg trays. Antimicrobial agents extend the life of the egg tray and ensure food safety.

Because the raw material cost of egg carton production is low, the profit of egg cartons is high, which is why many people produce egg cartons.

Egg carton production line process

The process of egg carton production and egg tray production is the same. They all need to go through the steps of pulping → egg carton forming → egg carton drying → egg carton secondary processing (optional) → egg carton packaging.

Main machines for making egg cartons

Egg carton pulper

The egg carton pulper is the first step of the egg carton production line that produces a homogeneous pulp from waste paper.

Egg carton forming machine

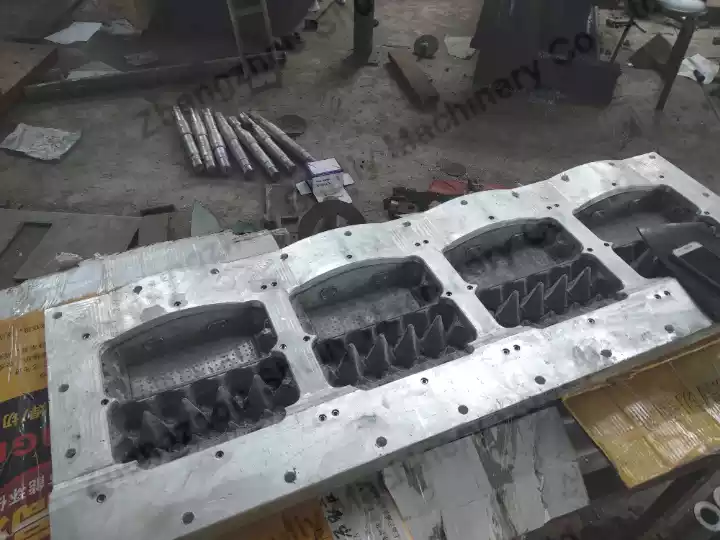

The egg carton forming machine is the most critical step in the egg carton production process. It adsorbs pulp into the shape of an egg carton using a mold and compresses it into shape.

Egg carton thermoforming machine

The egg carton hot pressed machine can be used to further shape and strengthen the egg carton by heating and pressing it in the machine’s mold.

Egg carton dryer

Egg carton dryers use hot air to remove moisture from egg cartons.

Egg carton drying method

As mentioned above, you can choose a multi-layer egg carton dryer, which is efficient and space-saving. The dried fuel can be selected in various ways such as gas or fuel oil. Compared with brick kiln drying, the biggest advantage of the dryer is that it saves fuel and at the same time can save about 30% of energy.

In addition, egg carton drying can use natural drying, which is suitable for small-volume production. You can also build your brick kiln for drying, which requires sufficient space.

Egg carton production line parameter

| Model | Capacity | Paper Consumption | Water Consumption | Energy Used | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kw/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kw/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kw/h | 3-4 |

| SL-5*12 | 6000pcs/h | 480kg/h | 900kg/h | 90kw/h | 3-4 |

| SL-6*12 | 8000pcs/h | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

The configuration of the egg carton production line, the degree of automation, and the size of the machine determine the output of egg cartons. This means that if you want to get 8000pcs of egg cartons in an hour, then you need to choose a line with high automation, high configuration, and a bigger machine.

How to produce egg boxes of different sizes?

The size of the egg carton is different for each egg carton manufacturer. Some require six eggs per carton, and some require 12 eggs per carton or 18 eggs per carton. So how does the egg carton machine produce egg boxes of different specifications? It is determined by the mold design of the machine. Therefore, the egg carton machine has various functions and can produce different sizes of egg cartons.

How are egg cartons of different colors produced?

We will see egg boxes of other colors in supermarkets or other places, not only white but how are the colorful egg boxes produced? In fact, during the production process of egg boxes, there is a very important pulping process. You can add dyes and coloring during the pulping process to produce egg cartons of different colors.

What is the difference between egg carton and egg tray production?

As we all know, there are two kinds of packaging methods for our common eggs. One is an egg tray and the other is an egg carton. What is the difference between the production methods of these two products? In fact, the production of raw materials and the production process of egg trays and egg boxes are the same.

The only difference in production is that the molds of egg tray forming machines for egg trays and egg boxes are different. Our molds can be customized according to customer needs. In this way, customers are more diversified in production and more competitive in sales.

Customer case about egg carton production line

There is a customer of a chicken farm in Cameroon who wants an egg carton machine production line. The customer has a chicken farm and wants to expand his business. So he chooses to process egg cartons, not only to meet the needs of his chicken farm egg boxes but also to be sold externally.

The customer ordered an egg carton production line, including a pulper, an egg carton former machine, a hydroforming machine, and an egg carton packing machine. After the machine was shipped to Cameroon, he was in full control of egg carton production within a week of production.

Before the purchase, we will send the production-related information of the egg tray to the customer, and the professional salesman will explain the use and structure of the machine. So customers can quickly produce egg cartons. If you are looking for an efficient egg carton manufacturing line, please feel free to contact us.