How Does Pulp Molding Reshape Branding and Consumer Experiences in FMCG?

In the fiercely competitive FMCG sector, how can brands stand out amidst the overwhelming array of products on store shelves? The answer has long transcended the product itself, extending to packaging.

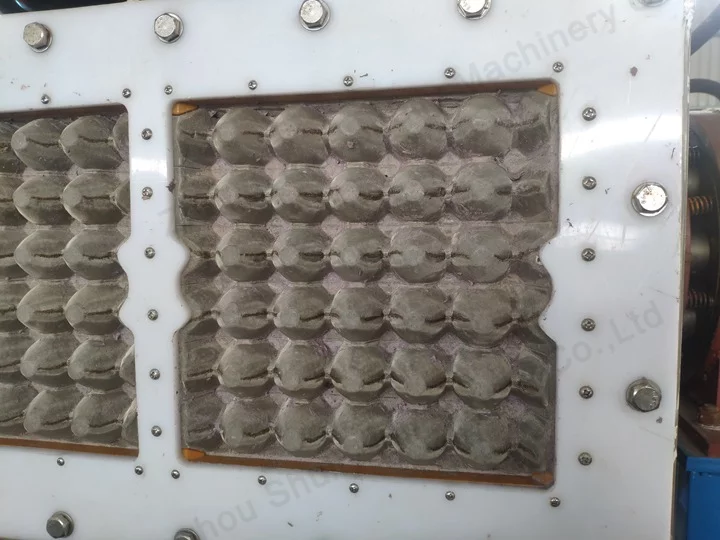

Pulp molding, this traditional technique utilizing waste paper as raw material, is making a powerful entry into the core of the fast-moving consumer goods industry with a fresh, innovative approach. The pulp molding machine that creates it is also undergoing continuous upgrades and evolution.

Aligning with the values of a new generation of consumers

Today’s consumers increasingly base their purchasing decisions on brand values. They are no longer merely price-driven followers but active practitioners of sustainable lifestyles.

Environmental sustainability as a core selling point: when your product packaging utilizes 100% biodegradable, recyclable pulp molding materials, you send a clear and powerful message to consumers. This resonates with their values and builds stronger brand loyalty.

Elevating the “unboxing experience”: the natural, rustic texture and warm tactile feel of pulp molding deliver a unique unboxing experience. Compared to cold, cheap plastic, pulp packaging conveys a sense of naturalness, premium quality, and thoughtful brand warmth.

Disruptive applications of pulp molding in three major FMCG sectors

The exceptional malleability of pulp molding breaks through the form limitations of traditional packaging, offering unprecedented creative possibilities for FMCG brands.

- Cosmetics and personal care sector

Challenge: beauty products demand both premium, luxurious aesthetics and precise internal cushioning to protect fragile bottles.

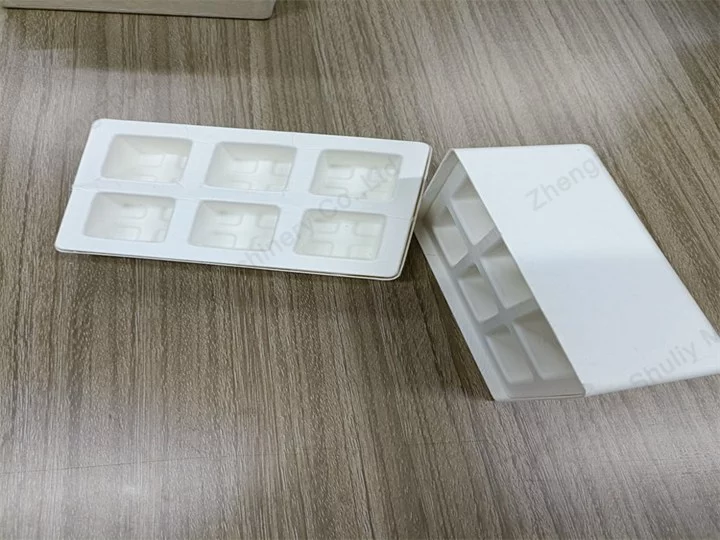

Opportunity: through dry or semi-dry molding techniques, pulp molding produces ultra-smooth surfaces and sharp-edged premium liners and gift boxes.

It can be dyed any color and perfectly conforms to irregular product contours. This delivers exceptional protection while projecting understated luxury.

- Food and beverage sector

Challenge: must comply with food-grade safety standards while offering moisture and oil resistance.

Opportunity: beyond traditional egg cartons and fruit trays, pulp molding is increasingly used for disposable dinnerware, takeout containers, and coffee cup sleeves.

With food-grade oil- and water-repellent additives, it can fully replace single-use plastic tableware.

- Consumer electronics

Challenge: requires exceptional cushioning performance and anti-static properties to protect intricate electronic devices.

Opportunity: pulp molding inserts serve as an ideal replacement for expanded polystyrene (EPS) foam.

They can be 3D molded to precisely match the contours of products like smartphones, headphones, and chargers, providing perfect form-fitting protection. Their superior cushioning capabilities, combined with the natural fiber structure, help prevent static buildup.

Shuliy’s pulp molding production line solutions

Having recognized the immense potential of pulp molding in the FMCG industry, you may wonder: How can you turn this opportunity into your own business reality? The answer lies in a set of efficient, reliable production equipment.

As an industry-leading pulp molding solutions provider, Shuliy Machinery offers you a complete range of equipment from entry-level to industrial-scale production. Our pulp molding machine production line is your ideal starting point to enter this golden opportunity.

Flexible customization: beyond producing standard egg cartons and fruit trays, our pulp molding machines effortlessly manufacture premium cosmetic inserts, electronic product cushioning packaging, coffee cup holders, and other FMCG packaging.

Complete solutions: we deliver turnkey projects encompassing pulping systems, forming systems, drying systems, and hot-press shaping systems. Each solution is tailored to your specific requirements—including output volume, automation level, and finished product quality standards—to provide the most cost-effective production plan.

Exceptional product quality: our equipment, particularly our high-end production lines equipped with hot-press shaping machines, consistently produces premium products featuring smooth surfaces, clean edges, and robust structural integrity.

Shuliy pulp molding machine for sale

From spotting opportunities to holding exquisite, sustainable packaging in your hands, this journey begins with the right technology. At Shuliy Machinery, our advanced pulp molding machines are your bridge to this future.

Don’t just read about the future of packaging—start creating it now. Contact us today for a free consultation on our customized pulp molding solutions.