Complete guide to egg tray drying: natural vs. mechanical

Egg tray production is an eco-friendly and profitable industry, but efficient drying plays a crucial role in the final product quality and production speed. This article breaks down both methods and helps you choose the most suitable one for your needs.

Overview of egg tray drying methods

After the egg trays are formed from pulp, they contain about 60–70% moisture. To make them strong and usable, they must be dried properly. There are two main drying methods:

Natural drying: sun-drying or air drying in open space.

Mechanical drying: drying using mesh belt dryers, trolley drying boxes, or brick kilns.

Natural drying: pros and cons

Advantages

Low cost: no need for expensive drying equipment.

Energy-saving: utilizes natural sunlight and air.

Simple setup: ideal for small-scale or rural operations.

Disadvantages

Weather dependent: drying time varies by season and climate.

Slow process: can take 4–24 hours.

Limited capacity: hard to scale up for large production.

Quality inconsistency: uneven drying may affect tray strength.

Mechanical drying: pros and cons

Advantages

High efficiency: drying time reduced to 15–30 minutes.

All-weather operation: runs regardless of the climate.

Scalable: supports mass production.

Consistent quality: uniform drying ensures better strength.

Disadvantages

Higher initial investment: cost of drying equipment.

Energy consumption: requires electricity, gas, or coal.

Which drying method is right for you?

| Scenario | Recommended Method |

|---|---|

| Small-scale, budget-limited setup | Natural drying |

| Large-scale or industrial production | Mechanical drying |

| Unstable weather conditions | Mechanical drying |

| Stable, sunny climate with low volume | Natural drying |

Our drying solutions

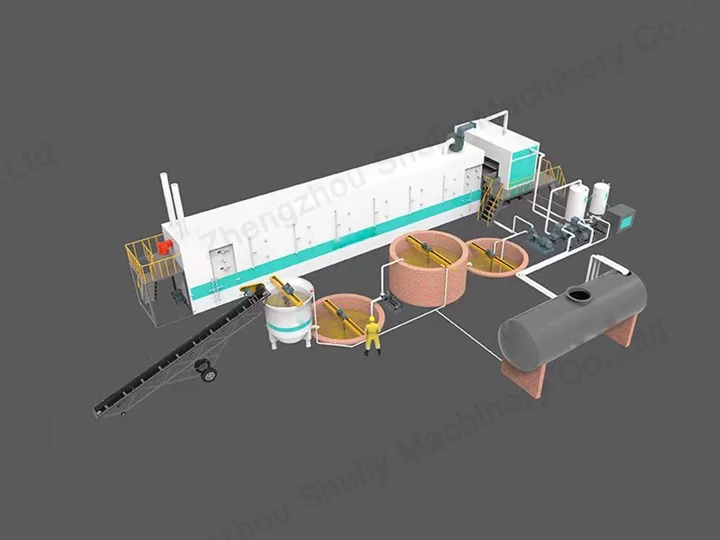

We provide multiple drying options tailored to your production scale:

Natural drying system layout guidance

Brick drying kiln (coal or wood-fired)

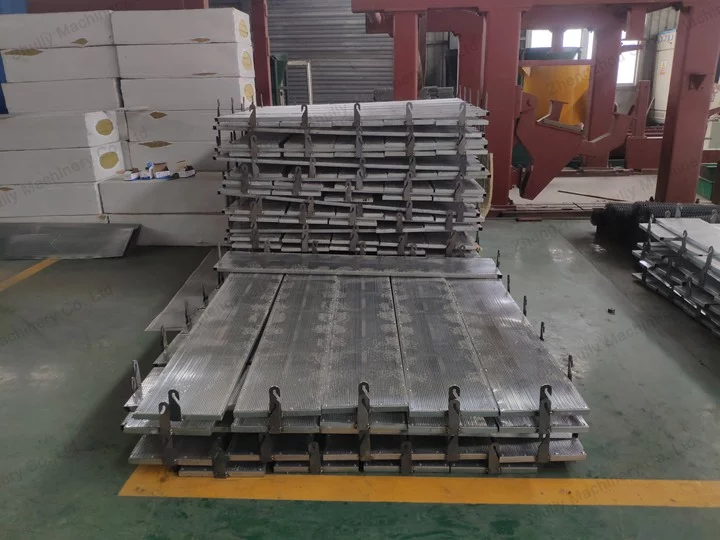

Multilayer metal drying line (electric or gas heated)

All dryers are compatible with our automatic egg tray production lines.

Conclusion

Choosing the right egg tray drying method can significantly influence your production efficiency, cost, and product quality.

If you’re aiming for high-volume, year-round production, mechanical drying is the clear winner. For those with limited investment and small batches, natural drying remains a viable option.