Egg tray dryer structure analysis and efficiency improvement methods

In the process of egg tray production, the moulded egg tray contains high moisture and must be dried efficiently before entering the packaging process. Egg tray dryer, as a key supporting equipment, is directly related to the production efficiency and quality of the finished product.

So, what is the structure of the common egg tray dryer composed of? What are the methods to improve the drying efficiency?

The basic structure of the egg tray dryer

Different types of egg tray drying equipment vary slightly in structural design, but mainly include the following core parts:

- Transmission System

The wet egg trays are output from the moulding machine and smoothly transported to the drying area by means of chains, rollers, or conveyor belts. The conveyor speed can be adjusted to suit different capacity requirements. 2. - Hot Air Circulation

The heat source generates hot air through a combustion chamber or heater, and the fan sends it evenly into the drying channel. Some systems are equipped with a hot air recovery function to enhance the utilisation of heat energy. - Drying Tunnel

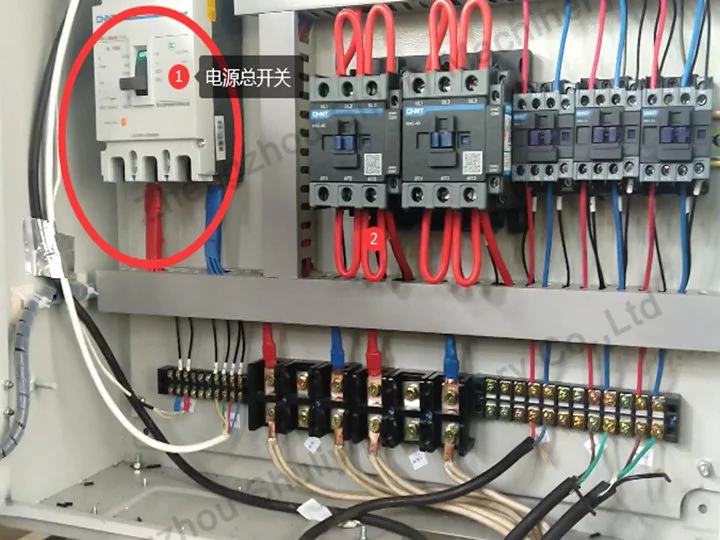

This is the core area of the egg tray drying process and is usually constructed as a multi-layer or single-layer structure with thermal insulation to ensure that no heat is lost. The internal design has a wind guide plate to optimise the distribution of hot air flow and improve the drying uniformity. - Control Panel

Contains a temperature controller, a conveying speed regulator, an alarm, etc., to ensure the stable operation of the equipment.

Comparison of common egg tray drying methods

Brick kiln drying room

Structural features: fixed brick walls and hot air ducts.

Investment cost: medium

Drying efficiency: uniform drying, weather restricted.

Internet loan dryer, trolley drying box

Structural features: modular design, easy to install, and move.

Investment cost: high

Drying efficiency: energy efficient, intelligent control.

Dry naturally

Structural features: no need for complex structures.

Investment cost: low

Drying efficiency: significantly limited by weather.

How to improve the efficiency of egg tray drying?

- Optimise the structure of the heat source

Choose burners with high thermal efficiency and match them with energy-saving insulation materials. A hot air circulation system can be considered to avoid energy waste. - Maintain a stable temperature and wind speed

Reasonably set the drying temperature and ventilation speed to avoid uneven drying or egg tray deformation caused by a large temperature difference. - Adjust the speed of the conveyor belt

According to the thickness and moisture content of the egg tray, set the appropriate drying time. In general, the drying time is 15~25 minutes. - Segment control temperature zone

Divide the drying channel into preheating zone, drying zone, and cooling zone. Each temperature control is designed to improve drying efficiency while reducing the risk of egg tray cracking. - Regular maintenance of the equipment

Clean the air ducts, check the combustion of the heat source, and maintain the conveyor system. Ensure efficient operation of the equipment and reduce the failure rate.

Advantages of our egg tray dryer

Modular structure: easy to transport and install, small footprint, suitable for rapid production.

Various heat source options: support for natural gas, electricity, diesel, and other fuels, to adapt to different regional resource conditions.

Full-automatic control system: adjustable temperature, wind speed, and conveying speed, improving drying stability and automation level.

Energy-saving design: high-efficiency heat insulation material and hot air recovery system, significantly reducing operating costs.

Improving the quality of egg trays starts with efficient drying

Choosing an egg tray production line equipment with a scientific structure and stable operation is the key to improving the quality of egg trays and factory productivity.

Shuliy Machinery will continue to be committed to providing high-performance egg tray production line equipment and technical support to global customers.

If you want to know the specific dryer configuration plan or get a quotation, welcome to contact us. We will provide you with one-stop egg tray production solutions.