2000pc/h pulp egg tray machine

| product | egg tray |

| model | SL-3*4 |

| output | 2000-2500pcs/h |

| paper consumption | 200kg/h |

| Water Consumption | 450kg/h |

| energy used | 58kw/h |

| work number | 4-5 |

| color | customizable |

You can now ask our project managers for technical details

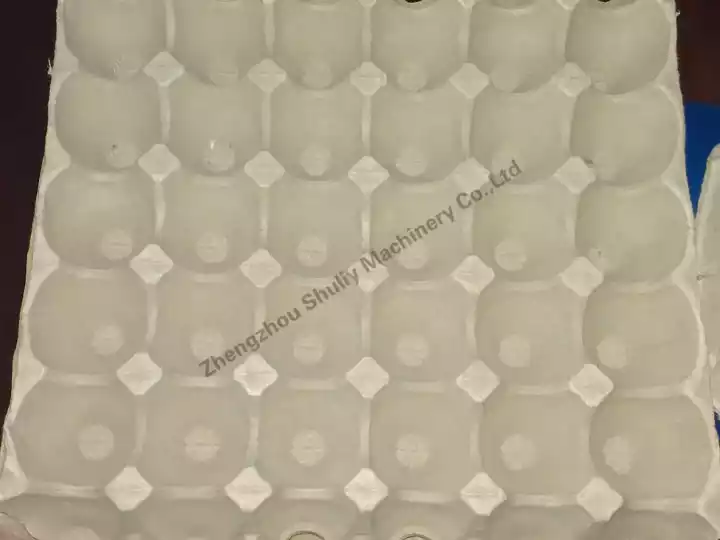

This pulp egg tray machine is an egg tray machine with an output of 2000pc per hour, and our egg tray production has 1000-8000 different configurations. The egg tray is recycled by using waste paper. After crushing, the egg tray is made. The normal size of the produced egg tray is 30 holes, and it can also be customized.

Why is the egg tray industry so popular?

There are three reasons for the popularity of egg tray production. First, the production cost of egg trays is low, and the cost of egg tray production, especially raw materials, is low. In addition, the production of egg trays is an environmentally friendly process, and the whole process of egg tray production is free of pollution and meets the environmental sanitation standards of various countries. Finally, egg trays are consumables, and egg tray manufacturers can have regular customers and stable orders. These are the reasons why egg tray production is so popular.

2000pc/h pulp egg tray machine parameter

| model | output | paper consumption | Water Consumption | energy used | work number |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

The minimum output of this pulp egg tray machine is 2000/h, and the highest can reach 2500pc/h, which has a certain relationship with the operation skills of the egg tray production line workers. After calculating, 200kg of paper and 450kg of paper need to be consumed in one hour. The ratio of water to paper is about 3:1.

Model selection of egg tray machine

Shuliy factory has egg tray production lines with different outputs of 1000-8000pc/h, which meet the needs of most egg tray production, among which 1000-2000pc/h egg tray production belongs to small-volume egg tray processing, suitable for family workshops Production. Or when a small factory processes egg trays, 8000pc/h is the maximum output. If you work 8 hours a day, you can produce 64,000pc per day, which can form a certain scale of egg tray processing.

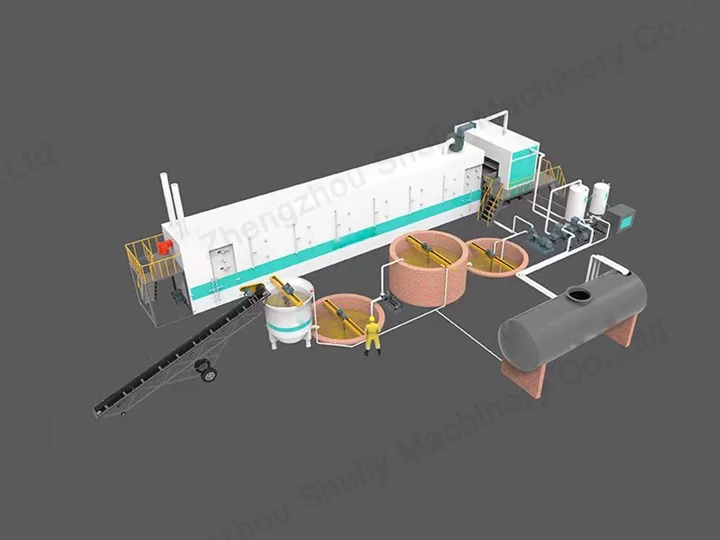

2000pc/h egg tray production equipment configuration

2000pc/h egg tray production requires a pulper, an egg tray forming machine, a dryer, and a baler. These devices form a complete egg tray production line.

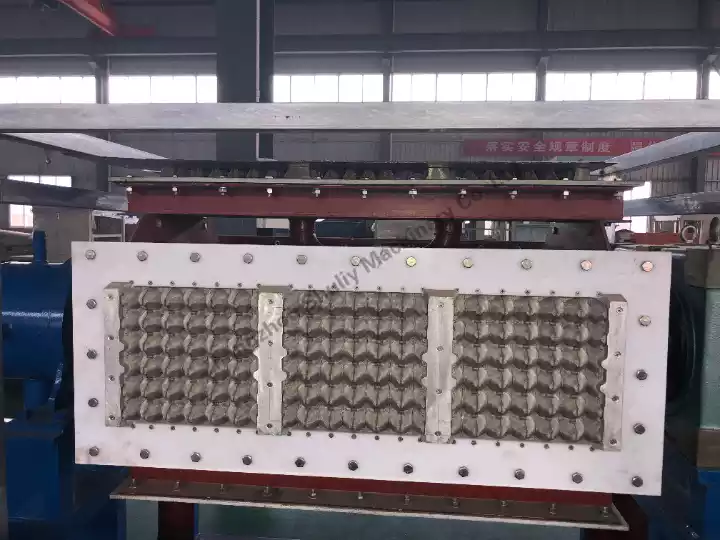

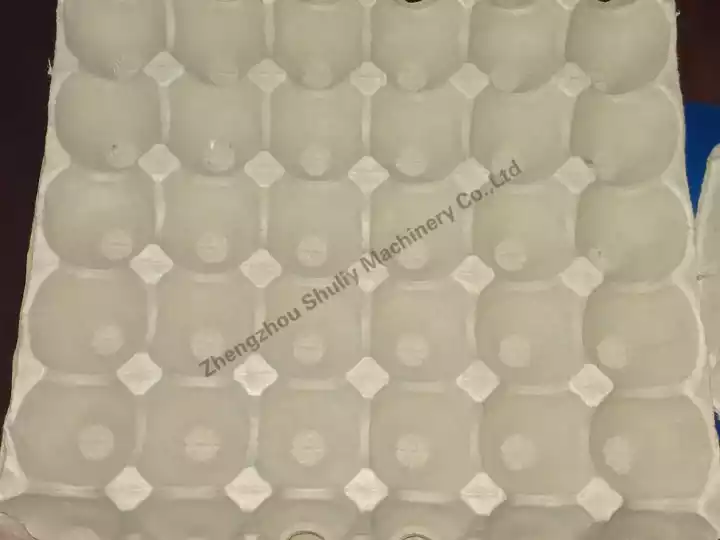

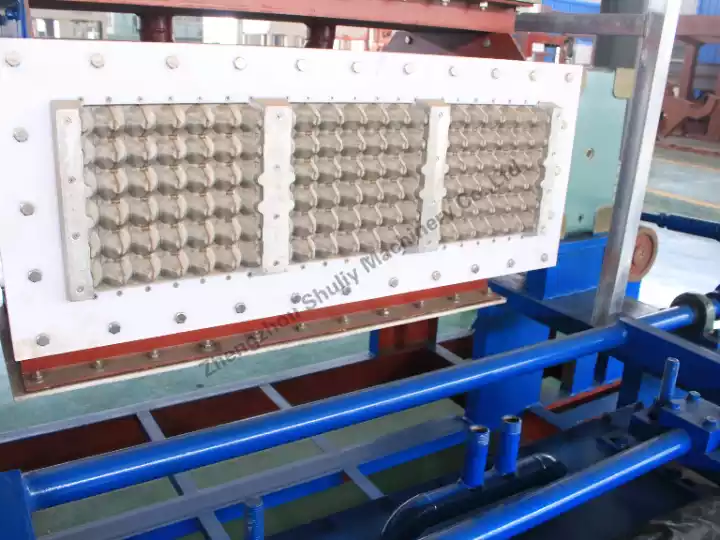

Pulp egg tray machine mold

The mold of the pulp egg tray machine has two materials, one is the egg tray made of plastic material, and the other is the egg tray made of metal material. Also a little more expensive. To make different types of egg trays, you only need to replace different egg tray molds, but in addition to making egg trays, metal egg trays are required to make other types of paper products. Because metal egg trays are made more finely, plastic egg trays cannot meet the requirements.

2000kg/h egg tray dryer

Natural drying of 2000kg/h egg trays can no longer meet the production needs. It needs to be dried with a metal egg tray dryer, or a brick kiln can be built for drying. The drying efficiency of the dryer is about 30-40 minutes, and the drying process can be fully automatic production.