Automatic paper egg tray production line

| model | SL-4*4 |

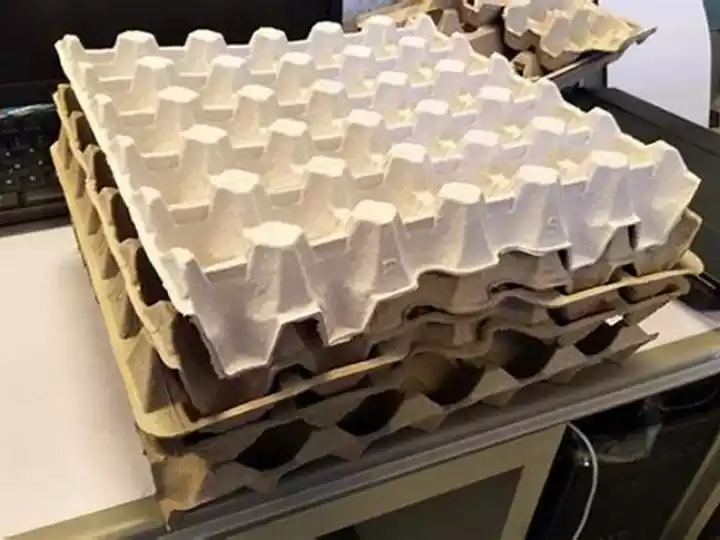

| product | egg tray |

| capacity | 3000-3500pcs/h |

| paper consumption | 280kg/h |

| Water Consumption | 560kg/h |

| energy used | 78kw/h |

| worker number | 4-5 |

You can now ask our project managers for technical details

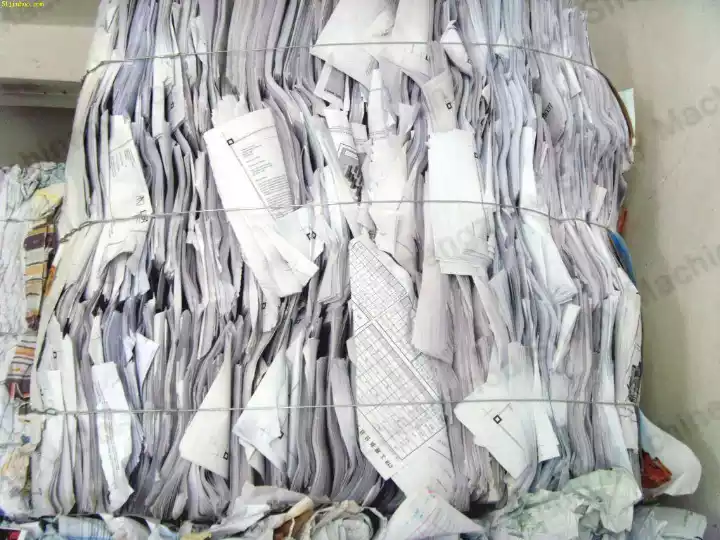

The automatic paper egg tray production line is a device used to produce egg trays. The egg tray machine uses waste paper to make egg trays, which is a very environmentally friendly product.

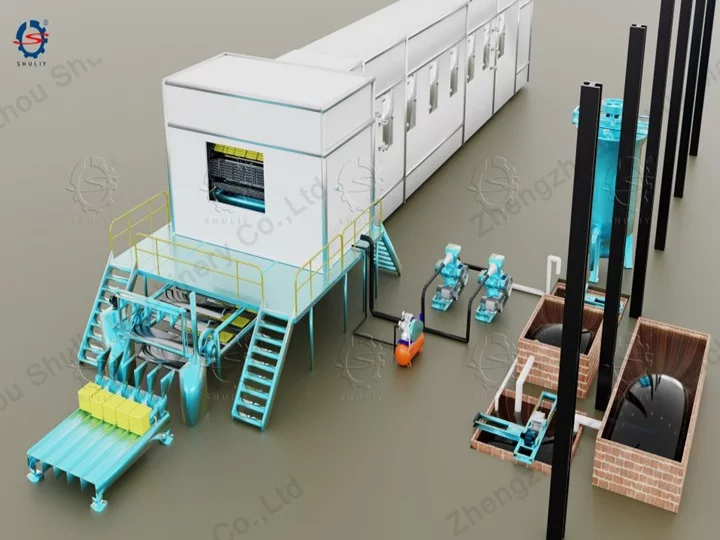

The paper egg tray production line mainly includes the pulping part, the egg tray forming part, the drying part, and the packaging part. The output of Shuliy’s paper egg tray production line is 1000-8000pcs/h.

How does the paper egg tray production line work?

Automatic paper egg tray production line process

Egg tray pulping

The production of the paper egg tray production line needs to build three pools, which are used for pulping, pulp storage, and a water storage pool, respectively. The required equipment is a hydraulic pulper. It needs to be stirred for nearly 40 minutes.

The specific production process is to pulverize the waste paper through a pulper, add water, and transport it to the pulp storage tank, and then put the pulp in the pulp storage tank into the pulp mixing tank to adjust the concentration of the pulp, which can be used. The homogenizer stirs the pulp evenly.

The pulp with a good consistency can be input into the pulp supply tank for processing. The structure of the pulping machine includes several parts: pulping machine, homogenizer, pulp pump, vibrating screen, and pulp disintegrating machine.

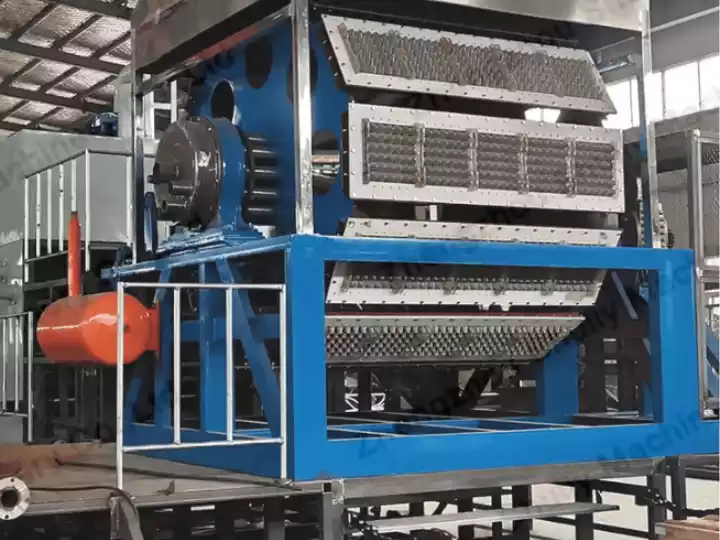

Egg tray forming

Molding is simply divided into two steps. In the first step, the pulp in the pulp supply tank is adsorbed onto the mold through the vacuum adsorption system. After the mold is adsorbed, it is transferred to the mold to form the shape of the egg tray.

In the second step, the egg tray adsorbed on the mold is transferred to the transfer system through the air compressor, and the machine can be automatically removed.

The structure of the egg tray forming machine includes an egg tray forming machine, mold, vacuum pump, negative pressure tank, water pump, air compressor, and mold cleaning machine.

Egg tray drying

The drying methods of egg trays are divided into natural drying, brick kiln drying, and dryer drying. The drying method is determined according to the output and local climate. With the paper egg tray dryer, the egg trays can be dried in a short time.

Hot press forming

The prepared egg tray is filled with water when it is just finished, but after drying, the moisture is reduced, and the surface of the egg tray will leave some wrinkles, which affects its use. But if you want the surface to be smoother, then you need to be hot-pressed with a hot press forming machine. And the formed egg tray will be more beautiful.

Egg tray packing

Packaging is the last step of the pulp egg tray production line. The egg tray packaging machine can stack multiple egg trays tightly together.

Egg tray machine parameters

| Model | Capacity | Paper consumption | Water Consumption | Energy used | Worker |

| SL-3*1 | 1000-1500pcs/h | 120kg/h | 300kg/h | 32kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

| SL-3*4 | 2000-2500pcs/h | 200kg/h | 450kg/h | 58kw/h | 4-5 |

| SL-4*4 | 3000-3500pcs/h | 280kg/h | 560kg/h | 78kw/h | 4-5 |

| SL-4*8 | 4000pcs/h | 320kg/h | 600kg/h | 80kw/h | 5-6 |

| SL-5*8 | 5000pcs/h | 400kg/h | 750kg/h | 85kw/h | 3-4 |

| SL-6*8 | 6000pcs/h | 480kg/h | 900kg/h | 90kw/h | 3-4 |

| SL-8*8 | 8000pcs/h | 640kg/h | 1040kg/h | 100kw/h | 3-4 |

Whether you are looking for small-capacity egg tray production equipment or a large-capacity egg tray machine. We can meet your needs. We have the machine with outputs of 1000pcs/h-8000pcs/h for you to choose from.

Advantages of the paper egg tray production line

- No pollution, the egg tray production process has no environmental pollution, but it belongs to the recycling resource utilization industry

- Low cost because the raw material is used paper, the cost is low

- Fully automated production, saving labor. The whole egg tray production process only needs 3-4 people

What raw materials can be used to produce the paper egg tray production line?

The production of egg trays can use waste cartons, waste books, A4 paper printing, or waste egg trays for recycling. Therefore, the raw materials for egg tray production are very extensive.

3D video of paper egg tray production line

Why is the egg tray machine welcomed?

After the statistics, it is found that the sales of egg tray machines are constantly increasing. During the process of docking with customers, we found that there are three main reasons for them to make egg tray machines.

First of all, the egg tray machine belongs to the resource recycling industry, which is very environmentally friendly and is also supported by the local government.

Secondly, the raw materials of the paper egg tray production line are easy to obtain. The raw materials used by the egg tray machine are mainly waste paper, which can be easily collected in many countries.

Finally, of course, it is very easy to sell egg trays. Chickens have a great demand for egg trays, and these are consumables, so it is easy to fix for customers. Many people are willing to choose to produce egg trays and make a profit because of it.

What is the pulping process of the egg tray?

Pulp mainly needs to control the ratio of water and pulp. Generally speaking, the ratio of water and pulp is 1:3 and is evenly mixed. A certain amount of glue or lime water needs to be added in the process, which can make the egg tray firmer. These are generally the work that needs to be done in the form of egg trays.

- Egg trays are produced using waste paper, and their quality is, of course, closely related to the raw materials.

- It is also related to the machine, the egg tray produced by a good-quality machine is stronger

- On the other hand, it is also related to production technology. The production of egg trays also has many skill points, such as the ratio of pulping and the number of additives, which need to be calculated without conducting experiments.

Employment arrangement of the paper egg tray production line

The production process of egg trays is probably understood, so how much labor do you usually need to build a complete egg tray industry? After experiments, it was found that only 4 workers were needed: one worker was required for egg tray pulping, one worker was required for egg tray molding, one worker was required for secondary processing of hot-pressed egg trays, and one worker was required for packaging.

Shuliy’s service

- Pre-sale detailed egg tray production process introduction, video tour of the factory

- Design machine placement and provide free online installation instructions

- After-sales problems are solved online, and technical problems in the production process can be helped to answered

FAQ

What is the production capacity of the egg tray machine?

From 1,000–8,000 pcs/h, depending on the model and drying system.

What types of egg trays can it produce?

30-cell egg trays, egg cartons, fruit trays, cup carriers, and other pulp molded products (by changing molds).

Can the molds be customized?

Yes. Aluminum or plastic molds can be customized based on your tray design.

Do you provide installation and after-sales service?

Yes. We offer layout design, online installation guidance, training, spare parts supply, and engineer support if needed.

Start your egg tray business today!

Contact our professional engineering team for a free project evaluation and quotation — we’ll help you design a profitable egg tray production plant tailored to your raw material supply, capacity, and budget.