1000pc/H Semi Automatic Egg Tray Making Machine

| model | SL-3*1 |

| output | 1000-1500pc/h |

| paper consumption | 120 kg/h |

| Water Consumption | 300kg/h |

| energy used | 32kW/h |

| Worker | 3-4 |

| raw material | waste paper |

You can now ask our project managers for technical details

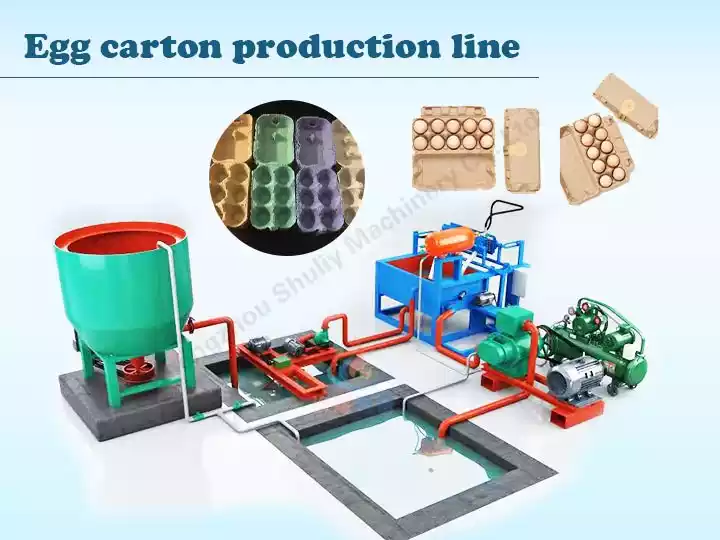

The semi-automatic egg tray making machine is a machine used to produce egg trays. This machine can use waste paper products to be processed into egg trays. This egg tray machine is a semi-automatic egg tray machine because customers who buy this type of egg tray machine generally dry it naturally. The main function of this egg tray machine is the forming of egg trays. The complete production line also includes egg tray pulping, egg tray hot pressing, and egg tray packaging machines.

Introduction of egg tray making machine

This 1000pc/h egg tray machine is also called a 3*1 type egg tray machine. The output of the machine is relatively small, and it can produce 1000 pieces per hour. It is suitable for a small family workshop production. Small egg tray machines belong to small output production. You can use the drying method of natural drying, which can reduce the cost. However, the local weather conditions need to be considered, so the drying time is uncertain. If the local weather temperature is not so high, you can also choose a dryer to dry the egg tray, and the production efficiency is higher

Egg tray production machine parameters

| model | output | paper consumption | Water Consumption | energy used | Worker |

| SL-3*1 | 1000-1500pc/h | 120 kg/h | 300kg/h | 32kW/h | 3-4 |

Staff arrangement of making egg tray

After the processing test, it was found that the number of workers employed for the egg tray was very small. The egg tray product line requires 4 people, namely 1 person in the pulping area, 1 person in the forming area, 1 person for packing after stacking, and 1 person for moving the warehouse. , a total of 4 people/class. Because the degree of automation of the machine is relatively high, it is only necessary to control the machine.

Semi-automatic egg tray making machine advantages

- The egg tray machine adopts a high-precision gearbox, which has accurate indexing, stable operation, and low noise.

- Using PLC automatic control system, automatic stack counting system, high degree of automation, saving labor costs, egg tray machine pulp tank and shield are made of stainless steel, corrosion resistance, long life.

- With specialized mold design engineers and mold manufacturing workshops, we can quickly design and manufacture various industrial packaging molds and other special molds, and provide customized services.

Egg tray making machine mold replacement

The mold of the egg tray machine can be replaced to produce different types of products, such as egg boxes, wine trays, fruit trays, and other products, mainly through the replacement of molds. For the production of egg trays, a tray can hold 12, 24, or 36 eggs, all of which can be processed.