4000–7000pcs/h Egg Tray Machine | Large Scale Paper Pulp Molding Equipment

| Product | egg tray machine |

| Capacity | 4000-7000pcs/h |

| raw material | waste paper pulp |

| step | egg tray forming |

| model | SL-4*8/SL-5*8/SL-6*8 |

You can now ask our project managers for technical details

Our large-scale egg tray machine with 4000-7000pcs/h capacity represents the pinnacle of industrial paper pulp molding technology. Designed for high-volume egg packaging production, this advanced equipment combines efficiency, reliability, and environmental sustainability to meet the demanding requirements of large-scale poultry operations, egg distributors, and packaging manufacturers.

Compared to smaller models, this equipment supports greater mold quantity, faster rotation, and heavier-duty components, making it ideal for industrial-scale packaging production.

Ingredients needed for egg trays

The selection of raw materials plays a crucial role in determining the quality standards, uniformity, and economic efficiency of egg tray production. Therefore, which primary materials serve as the foundation for egg tray manufacturing processes?

A significant benefit of egg tray manufacturing equipment lies in its ability to utilize diverse locally available materials as feedstock. Such materials encompass recycled newsprint, used cardboard packaging, paper production waste, and agricultural residues, including sugar cane fiber, wheat stalks, and processed bamboo material.

Egg tray machine and paper tray application

This machine is designed for producing various pulp-molded packaging trays, including:

- Egg trays

- Duck egg trays, quail egg trays

- Fruit trays, apple trays

- Industrial packaging trays

The above can be achieved by simply changing the shape of the mold.

Then our large-scale egg tray machine serves various industries and applications:

- Commercial egg farms: large poultry operations requiring high-volume packaging solutions

- Egg processing plants: industrial facilities processing and distributing eggs

- Packaging companies: manufacturers specializing in biodegradable packaging products

- Agricultural cooperatives: farmer cooperatives need cost-effective packaging solutions

- Export operations: companies requiring standardized packaging for international markets

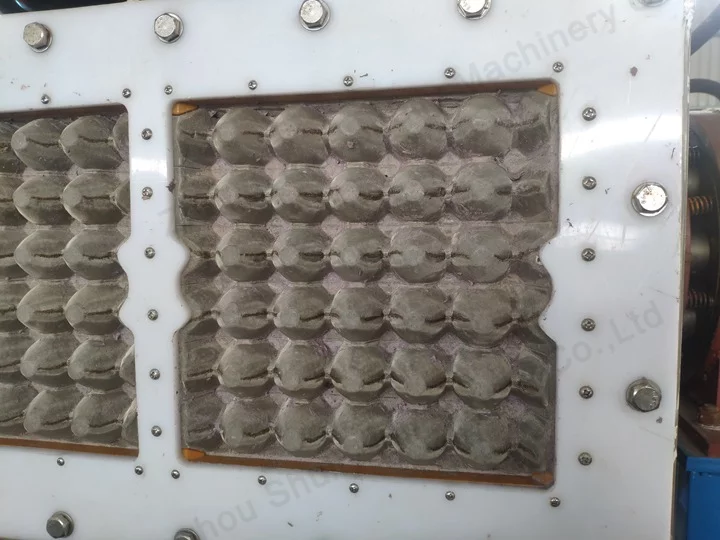

Egg tray forming machine structure

The egg tray machine is composed of the following core modules:

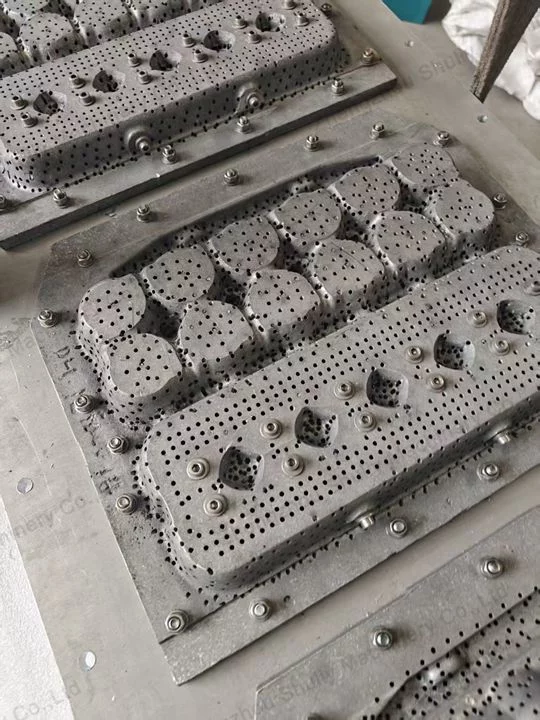

Rotary molding rollers: 4-6 rows (32-48 molds) for efficient molding.

High precision molds: made of aluminum alloy or copper for better shape and longer service life.

Main drive motor and gearbox: smooth speed control and strong power output.

Vacuum suction system: effective separation of water and pulp for fast molding.

Technical parameters of the egg tray machine

| Model | Molds (rows×columns) | Forming Molds Qty | Output (pcs/h) | Installed Power |

| SL-4×8 | 4 rows × 8 columns | 32 | 4000–5000 | 90–120 kw |

| SL-5×8 | 5 rows × 8 columns | 40 | 5000–6000 | 110–140 kw |

| SL-6×8 | 6 rows × 8 columns | 48 | 6000–7000 | 130–160 kw |

Key features of the 4000–7000 pcs/h egg tray machine

High output: up to 7000 pcs/h with 48-mold rotary forming

Precision engineering: balanced rotating system with low vibration

Durable molds: aluminum or copper molds ensure long-term reliability

Stable running: heavy-duty gear reducer and chain drive

Intelligent control: supports automatic lubrication

Customizable layout: adaptable to various workshop environments

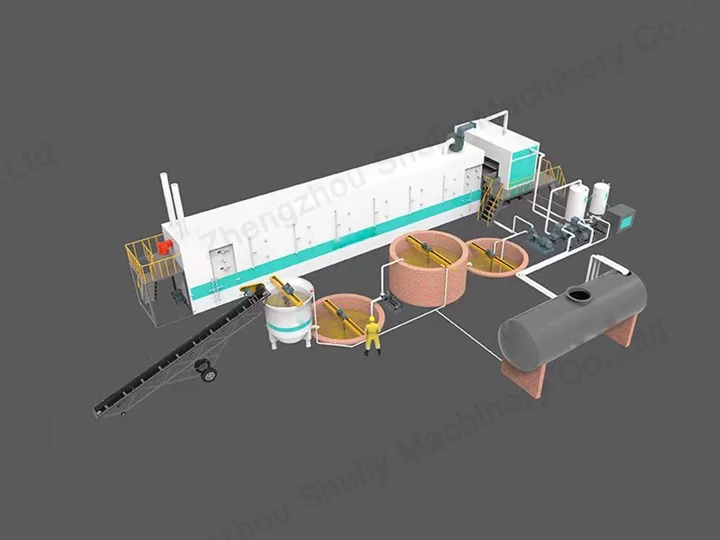

Large-scale paper pulp molding production process

- Pulp preparation: feed waste paper materials into the pulp preparation unit, incorporate the required water volume for mixing, and agitate thoroughly.

- Transportation: the blended pulp mixture is transferred to the pulping equipment via the pulp transport system.

- Pulp processing: mix and regulate the pulp within the pulping unit to achieve the optimal consistency required for molding operations.

- Molding: the prepared pulp is transformed through the molding apparatus to create the egg tray configuration.

- Dewatering: apply pressure to the molded egg tray to extract surplus moisture content.

- Drying: position the dewatered egg tray within the drying chamber for complete moisture removal.

- Automated packing: the cured egg trays undergo packaging through automated packing equipment, facilitating efficient transport and storage.

Automatic egg tray production process working video

Why choose us?

Proven Track Record

With over 10 years of experience in pulp molding technology, we have successfully installed more than 500 production lines worldwide. Our machines operate reliably in diverse climatic conditions and have earned recognition from industry leaders.

Comprehensive Service

From initial consultation to after-sales support, we provide complete solutions including:

- Feasibility studies and project planning

- Custom design and engineering

- Installation and commissioning

- Training and ongoing support

Quality Assurance

All of our machines undergo rigorous testing and quality control procedures. And all of them are provided with a test machine, packaging, and shipping video before shipment.

Competitive Pricing

Our direct factory pricing eliminates middleman costs, providing exceptional value for your investment. Flexible financing options and leasing programs are available to suit different budget requirements.

FAQ

Can I use my mold design?

Yes. We support custom mold production based on your sample or CAD drawing.

Does this machine include the drying or pulp system?

This machine focuses on the molding only. We can provide matching systems separately.

What type of waste paper can be used as raw material?

The machine can process a variety of waste paper types, including newspapers, magazines, office paper, and cardboard. The paper should be free from plastic coatings and excessive ink content.

Contact us

Seeking a dependable, high-output egg tray forming machine for your packaging needs?

Contact us for a detailed quotation, mold samples, and 3D workshop layout design.