Cyprus Customer Invests in 4*8 Egg Tray Forming Machine to Expand Egg Packaging Business

A professional egg farming and supply company in Cyprus recently purchased a 4*8 egg tray forming machine with an integrated pulping system from Shuliy. The investment enabled them to produce 4000–5000 egg trays per hour, significantly reducing packaging costs and improving overall efficiency.

With this equipment, the client not only gained control over tray production but also strengthened their ability to handle bulk orders and streamline their logistics.

Customer background and needs

Located in Cyprus, the client operates a medium-sized egg production facility, supplying eggs to supermarkets, restaurants, and wholesale distributors. Due to the country’s agricultural focus and growing demand for local produce, packaging capacity became a bottleneck in the client’s operations.

Previously relying on third-party suppliers for egg trays, the client faced frequent delays and increasing costs. To solve this, they sought to establish an in-house tray production line that was cost-effective, scalable, and easy to manage. They required a machine that could:

- Handle large-scale continuous production

- Be configured for local voltage and plug types

- Produce standard-size 30-cell egg trays

- Integrate smoothly with their existing factory layout

The customized solution we provided

Based on the client’s site layout and production requirements, we supplied a complete egg tray production line, including:

- One 4*8 egg tray forming machine

- One hydraulic pulper

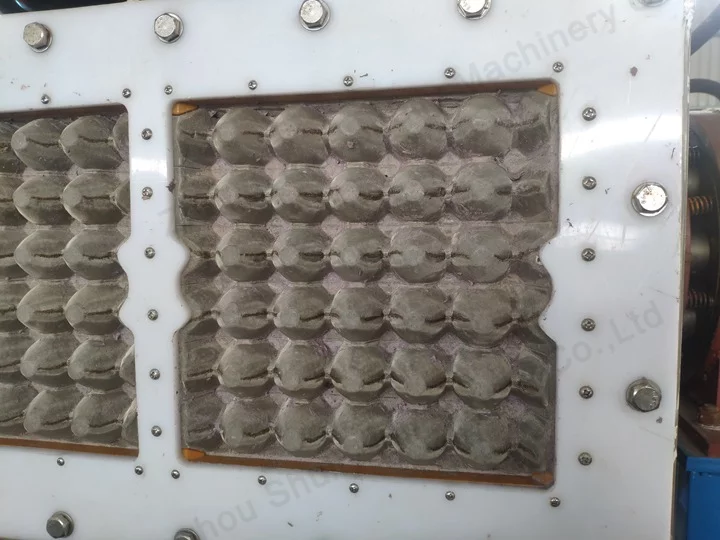

- Mold set for standard 30-cell egg trays

- Customized voltage configuration (3-phase 380V, 50Hz) and local plug type

- Technical layout drawing to assist with installation

This configuration allowed the customer to start independent tray production with minimal setup time and high operational efficiency.

Test video before shipment

Why choose Shuliy’s 4*8 egg tray forming machine

Our 4*8 egg tray machine was the ideal solution for the client’s production needs, offering the following advantages:

High output: 4000–5000 pieces/h, suitable for medium to large farms

Customizable molds: optional aluminum or plastic molds for various tray types

Flexible configuration: voltage and plug types adapted to Cypriot standards

Energy-efficient operation with reduced water and electricity consumption

Easy to operate: requires minimal labor, supporting semi-automatic and fully automatic options

Shuliy’s service advantages

We provided comprehensive services to ensure the client had full confidence in their purchase:

- Test video of the 4*8 machine before shipment

- Detailed packaging photos and confirmation before dispatch

- Protective film wrapping for all core components

- Reinforced wooden crates for overseas transport

- On-site product inspection via live video call

Every piece of equipment was carefully inspected, packed, and delivered with international shipping safety standards in mind.

Positive feedback and successful installation

After receiving the equipment, the Cypriot client praised the professional packaging and fast delivery. Our technical team provided remote video guidance for machine installation, mold calibration, and pulping system setup.

The customer expressed great satisfaction and indicated plans to order a drying system from Shuliy shortly to further automate their production.