South African clients adopt egg tray drying box to automate egg tray production

How can egg tray production be upgraded from traditional sun-drying to an all-weather, high-efficiency industrial process? This is precisely the core challenge our South African client addressed by introducing our multi-layer metal egg tray drying line.

Client background and core requirements

Our client operates a medium-sized poultry farm in South Africa, complemented by pulp egg tray production for both internal use and external sales. Certain regions of South Africa experience prolonged rainy seasons with high humidity, creating significant uncertainty for egg tray production that relies on natural air-drying.

The client consistently faces the following challenges:

- Extended drying cycles, with complete drying taking days during the rainy season.

- Substantial land area required for drying, limiting factory expansion.

- Inconsistent drying results in insufficient strength and high deformation rates of finished egg cartons, compromising product quality.

As the capacity of their egg carton forming machines increases, the outdated drying process has become the primary bottleneck constraining their growth.

Tailor-made solutions

During the project’s initial phase, we thoroughly assessed the hourly output of the client’s egg tray forming machine. Based on a production rate of 3000pcs/h, we precisely calculated and configured an egg tray drying box with corresponding length and tier specifications.

This ensures drying speed perfectly matches forming speed, eliminating production bottlenecks. Additionally, we provided a complete heat source system including a hot air furnace, an induced draft fan, and a chimney.

Core advantages of our egg tray drying box

Addressing customers’ key concerns regarding efficiency, stability, and footprint, we highlighted the critical technical features of our egg tray drying chamber:

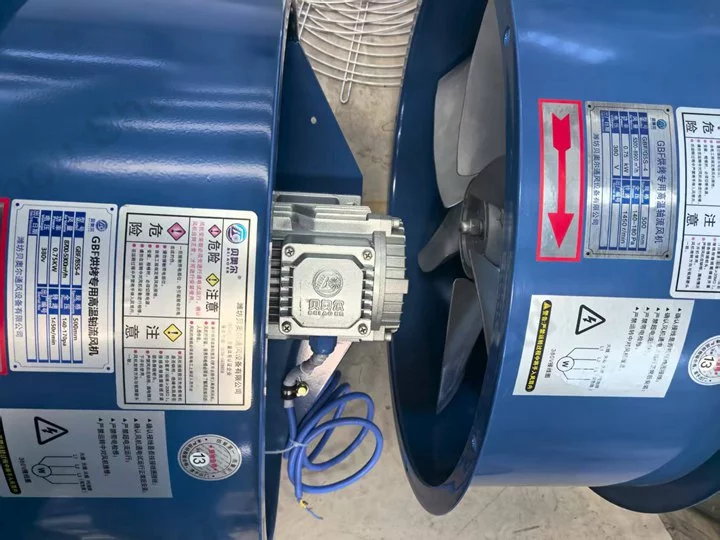

Uniform hot air circulation system: the chamber incorporates scientifically designed hot air circulation ducts. Paired with high-power, high-temperature-resistant fans, this ensures that hot drying air from the furnace uniformly penetrates every egg tray across all layers.

Intelligent temperature control and stable transmission: the equipment features an intelligent temperature control system that precisely sets and maintains optimal drying temperatures based on the moisture content of the egg trays.

Premium insulation and durable structure: the chamber utilizes thickened rock wool or alumina silicate insulation boards, delivering outstanding thermal insulation. This effectively minimizes heat loss and reduces fuel consumption.

Why choose Shuliy?

We eliminate customer concerns through unparalleled transparency and reliability. Before shipping equipment, we:

Provide operational videos: we capture footage of identical drying chambers in operation at other factories, along with test videos of our factory’s drive systems and control cabinets.

Ensure meticulous, secure packaging: we individually wrap components like trolleys and pack them into sturdy wooden crates meeting international shipping standards, photographing the process for customer verification.

Support real-time video inspection: before packing, we proactively invite customers to join a video call. This allows them to inspect the material quality of every component in real time and from all angles, ensuring what they see is what they get.

Positive customer feedback and successful operation

Upon arrival at Durban Port, the customer highly commended our professional packaging, which greatly facilitated rapid on-site installation. During the installation phase, our engineers guided the local team through detailed 3D assembly drawings and remote video calls, ensuring the successful assembly and commissioning of the drying room.

Today, the client has doubled their egg tray production capacity while maintaining stable and reliable product quality. This success has secured long-term supply contracts with several major supermarket chains.