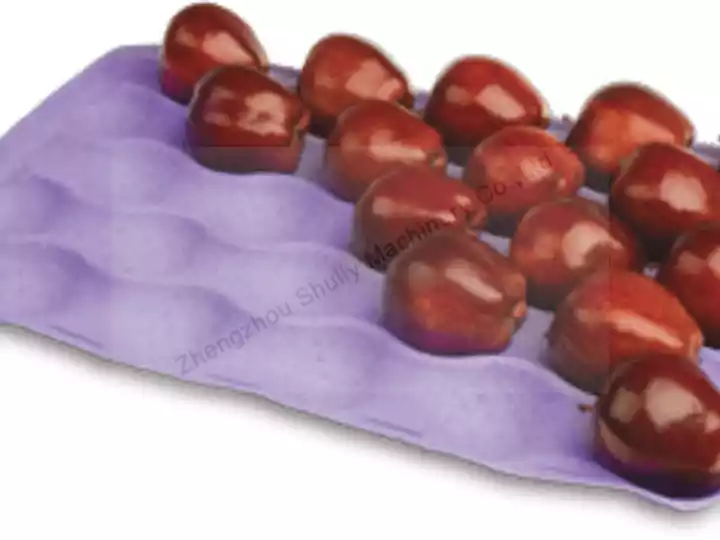

What materials are needed to produce apple trays?

The working principle of apple tray forming machines is essentially the same as that of egg tray machines—both produce pulp trays through pulping, forming, and hot-press drying. However, during actual factory construction, one of the key concerns for clients is:

What is the best raw material for apple tray production? Waste paper? Paper pulp? Or wood pulp? Is there a significant difference in cost and quality?

Today, we’ll analyze the advantages and disadvantages of these three common materials from three perspectives: production cost, finished product quality, and stability. This will help you quickly make the right material choice.

Waste Paper Materials

Waste paper is the most common and cost-effective raw material source in apple tray production, including: discarded packaging paper, cardboard boxes, corrugated paper, waste newspapers, and recycled pulp blocks.

Advantages:

- Low-cost raw materials: suitable for mass production with fast return on investment

- High adaptability: compatible with most apple tray molds

Target audience: new factories with limited budgets, seeking rapid production ramp-up, and without stringent requirements for finished product appearance.

If you’re planning to build an apple tray production line, the waste paper pulping and automatic forming machine solution offers the best cost-performance ratio and fastest return on investment.

Virgin pulp

Virgin pulp refers to unprocessed paper fibers sourced from wood or bamboo pulp, free of impurities and featuring longer fibers.

Advantages:

- Whiter color and premium appearance

- Superior load-bearing capacity, ideal for exporting fruit trays

- Faster molding with lower scrap rates

Disadvantages:

- 30–80% higher cost than recycled paper

- Requires stricter pulp mixing ratio control

Suitable for: premium apple trays, high-end fruit gift box packaging, export product factories

If your target market includes premium fruit retailers, boxed exports, or gift packaging, the pulp properties enable higher product pricing and greater gross margins.

Wood Pulp Raw Material

Wood pulp is the preferred material for manufacturing high-end molded pulp products. Its fibers are strong and resilient, offering excellent toughness and optimal molding performance.

Features:

- Intact fiber structure far superior load-bearing capacity compared to recycled paper

- Smooth surface, attractive color. Suitable for suppliers with high branding requirements

- Low finished product shrinkage, more precise and standardized molding

Wood pulp is typically used for premium fruit trays, supermarket premium sections, and high-end gift-boxed fruits. If you’re producing mass-market or wholesale items, it may create cost pressures.

So which raw material should we choose?

| Raw materials | Recommended Candidates | Product Positioning |

|---|---|---|

| Waste paper | Pursuing low costs and mass production | Mid-range market, basic fruit tray |

| paper pulp | Need more attractive and durable products | Export fruit trays, premium packaging |

| wood pulp | High profit premium fruit trays | Ultra-high-end, bespoke clients |

We also support factory trials and will help formulate the optimal pulping solution based on the raw materials you have available.

Looking to build an apple tray production line?

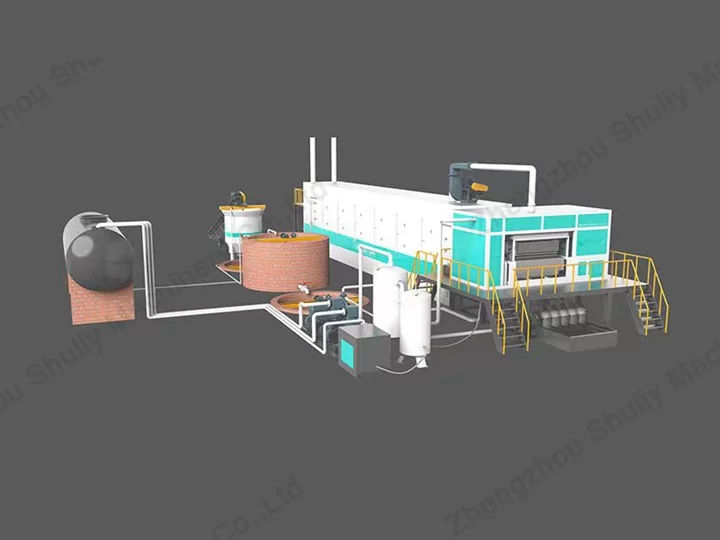

We can provide you with a complete turnkey solution! We provide a complete apple tray forming equipment suite:

- Pulping System

- Apple Tray Forming Machine (supports multiple mold specifications)

- Hot Pressing and Shaping Machine

- Drying Line

- Packaging System

Simply tell us: daily output / raw material type / finished product dimensions. We’ll provide free factory configuration and investment budget.

Contact us now for a quote and solution! You invest, we make sure your equipment turns a profit!