3000pcs/h paper pulp egg tray machine

| Product | paper pulp egg tray machine |

| Capacity | 3000pcs/h |

| raw material | waste paper pulp |

| step | egg tray forming |

| model | SL-4*4 |

You can now ask our project managers for technical details

A paper pulp egg tray machine is equipment that uses pulp to produce paper egg trays. Egg trays are a common packaging material used to protect the transportation and storage of fragile products such as eggs. The pulp egg tray machine is easy to produce, highly profitable, and environmentally friendly. So many chicken farms, waste paper recyclers, and investors started egg tray production projects. There are many models of egg tray machines; this one is a 3000pcs/h egg tray machine.

Ingredients for the egg tray machine

The quality, consistency, and cost control of egg trays depend to a large extent on the choice of raw materials. So, what are the dominant raw materials behind egg tray moulding?

One of the biggest advantages of the egg tray moulding machine is that a wide range of raw materials can be sourced locally. These raw materials include used newspapers, corrugated cartons, printing trimmings, and even crop waste such as bagasse, straw, and bamboo pulp.

Most of the raw materials for egg trays are widely available, easily accessible, and inexpensive. Africa, South-East Asia, Latin America, and other places with abundant waste paper resources and low-cost access are particularly well suited to the development of the egg tray manufacturing industry.

Machine types of egg tray machines

Egg tray machines are divided into automatic egg tray machines and semi-automatic egg tray machines. The egg tray machines in our factory are fully automatic egg tray machines. The difference between the two egg tray machines is as follows.

Semi-automatic egg tray machine

A semi-automatic egg tray machine is a small model machine for making egg trays, also known as a semi-automatic paper egg tray forming machine. The semi-automatic egg tray machine needs to manually place the egg tray mold in the machine, and then start the machine for production. Compared with the fully automatic egg tray machine, the production process of the semi-automatic egg tray machine requires a certain degree of manual operation.

Automatic paper pulp egg tray machine

Compared with the semi-automatic egg tray machine, the production process of the automatic egg tray machine is more automated and efficient, without manual operation, and is suitable for large-scale production. The whole egg tray production needs 4 people to complete.

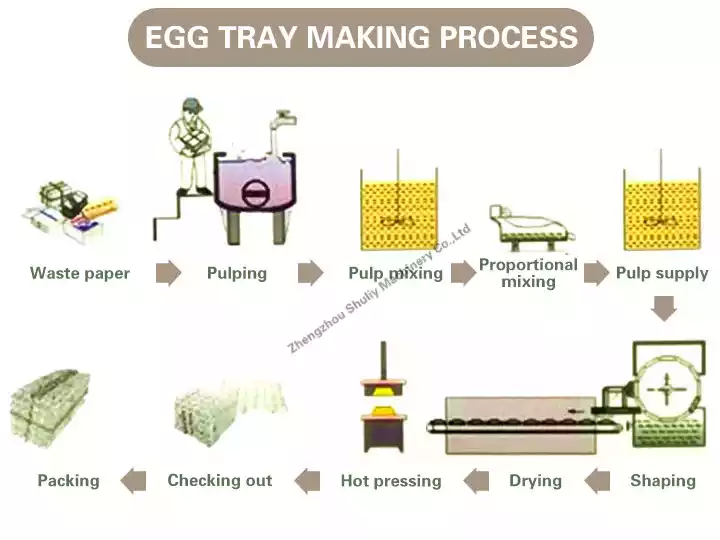

Fully automatic egg tray production process

1. Pulp conditioning: put the waste paper into the pulp conditioning machine, add an appropriate amount of water to mix, and stir.

2. Pulp conveying: the mixed pulp is conveyed to the pulp machine through the pulp conveyor.

3. Pulping: stir and adjust the pulp in the pulper to make the pulp reach a suitable concentration for forming.

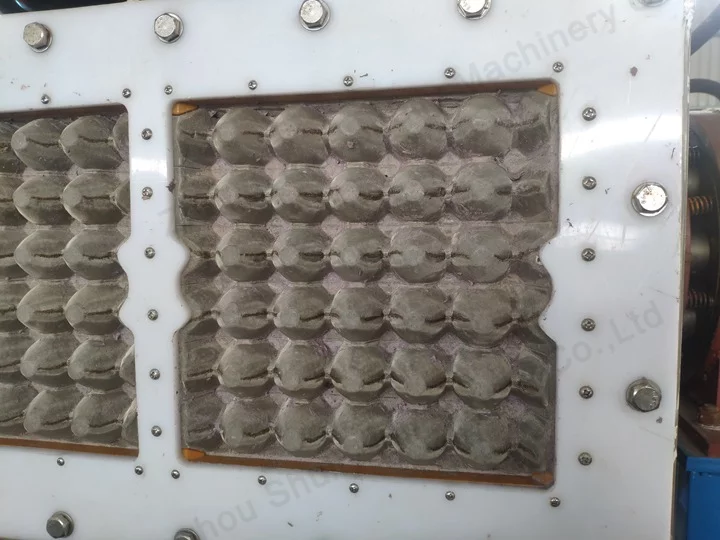

4. Forming: the pulp is shaped by a forming machine to form the shape of an egg tray.

5. Pressing water: press the formed egg tray with water to remove excess water.

6. Drying: place the pressed egg tray in a dryer to dry it completely.

7. Automatic packaging: the dried egg trays are packaged by an automatic packaging machine, which is convenient for transportation and storage.

Automatic egg tray production process working video

3000pcs/h paper pulp egg tray making machine parameters

| model | output | power | worker | paper consumption /h | water consumption /h | drying method |

| 4*4 | 3000pcs/h | 45kw | 4 | 240kg | 480kg | Brick kiln drying or metal dryer |

3000pcs/h paper pulp tray machine features

- Efficient production: The production speed of 3000pcs/h can meet the needs of large-scale production, and it is the choice favored by many egg tray producers.

- High stability: The machine has been tested many times and by customers, which proves that the machine is very stable and has a long service life.

- Simple and easy to operate: the paper pulp egg tray machine is easy to operate, and the operation of the egg tray machine is very simple. You can understand the operation of the machine through videos and instructions.

- Environmental protection and energy saving: the paper pulp egg tray machine uses pulp as raw material, and no chemical substances are added in the production process, which is in line with the concept of environmental protection and sustainable development.

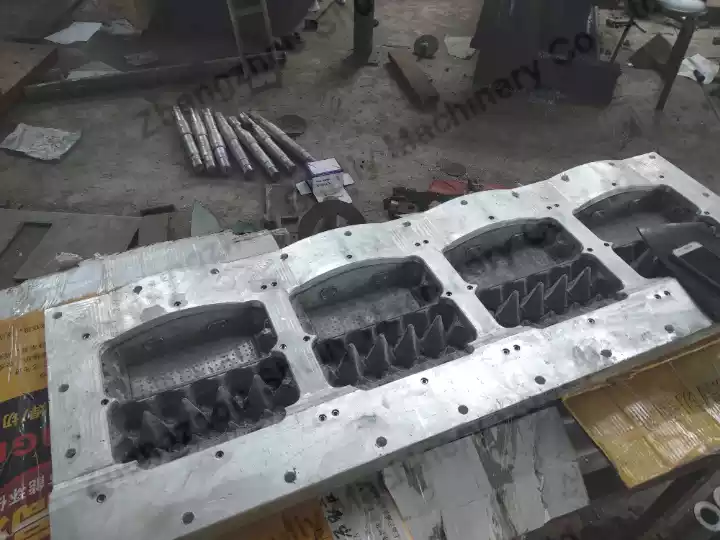

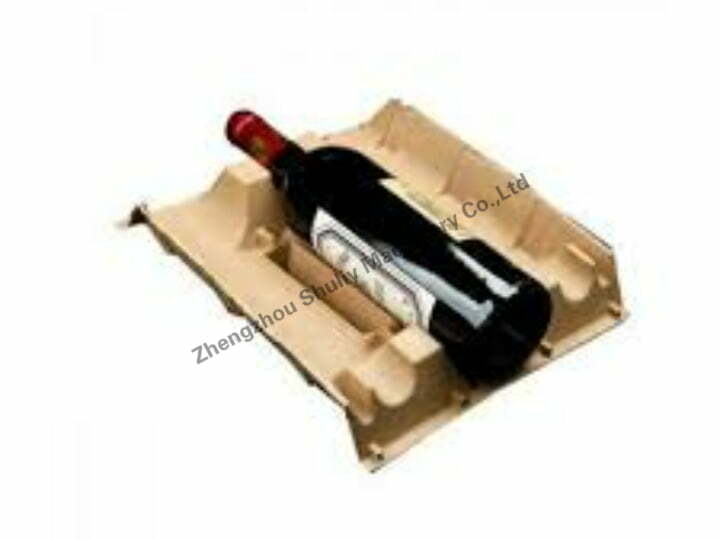

- Diversification of moulds: customized moulds are available to fit many types of paper tray products. For example, egg tray, wine tray, fruit tray, and shaped tray.

Application field of the egg tray machine

- Egg Production Industry: Egg trays are an important packaging material to protect eggs, so the egg production industry is the main market for egg trays. The egg production industry is trending favorably with the increasing global population and increasing demand for high-quality eggs, which will further drive the demand for egg trays.

- Food processing industry: Egg trays can not only be used for the packaging of eggs and other foods, but also can be used for the packaging of other foods, such as fruits, vegetables, meat, etc. As people’s requirements for food safety and hygiene are getting higher and higher, the demand for egg trays in the food processing industry is also increasing.

- Transportation industry: By changing the mold, the egg tray machine can be used for the packaging of many precision instruments and as a packaging box for fixed products

- Agricultural production industry: Seedling trays are generally made of degradable paper materials, and paper seedling trays can be produced by egg tray machines.

Why choose the Shuliy egg tray making machine?

As an experienced paper tray equipment manufacturer, Shuliy has successfully exported egg tray machines to more than 30 countries. This includes Indonesia, Saudi Arabia, Georgia, Peru, and others.

Our services include:

Machine voltage and plug customisation to meet national standards.

Provide test machine video and remote installation guide before shipment.

The machine is shipped in a wooden case and encapsulated with rust-proof film to ensure the safety of long-distance transport.

After the purchase of the machine, provide project consulting and programme recommendations to help customers choose the type of not stepping into the pit.

FAQ

Which ingredients are suitable for the egg tray machine?

Egg tray machine mainly uses waste paper (such as old newspaper, book paper, corrugated paper, carton trimmings) mixed with water to make pulp.

What products can I make with a pulp tray making machine?

In addition to egg trays, moulds can be modified to produce fruit trays, shoe trays, cup trays, industrial cushioning trays, and other pulp-moulded products to meet different market demands.

How productive is an egg tray making machine?

We offer a wide range of models, from 1,000 pieces per hour to 8,000 pieces per hour, which are suitable for the different needs of home workshops, small factories, and large enterprises.

Is installation and technical support available?

We provide complete operation manuals, installation videos, remote video guidance, or we can send engineers to the local area for installation guidance.

Welcome to the Shuliy egg tray machine factory visit

We welcome guests from all over the world to visit our facility and offer flight and hotel services. Please contact us if interested!