1500pcs/h egg tray forming machine | egg tray molding machine

| model | SL-4*1 |

| egg tray size | 30*30cm |

| output | 1500-2000PCS/h |

| paper consumption | 160kg/h |

| Water Consumption | 380kg/h |

| energy used | 380kg/h |

| worker number | 3-4 |

You can now ask our project managers for technical details

This machine is a 1500pcs/h egg tray forming machine. When purchasing, you can choose according to the egg tray output you want to add functions. We have a 1000pcs/h-5000pcs/h egg carton making machine.

Of course, different machine models have different structures. This 1500pcs/h egg tray forming machine has been exported to Brazil, Turkey, the Philippines, Nigeria, and other places.

Advantages of small scale egg tray forming machine

- A small scale machine means low cost. You can have a high-quality egg tray forming machine for very little money.

- Easy to operate. It can be easily operated by only 3-4 workers.

- Just change the molds, you can use this machine to make coffee trays, fruit trays, shoe trays, and so on.

Egg tray molding machine parameters

| model | output | paper consumption | water consumption | energy used | worker number |

| SL-4*1 | 1500-2000PCS/h | 160kg/h | 380kg/h | 45kw/h | 3-4 |

This egg tray forming machine can produce 1500 egg tray machines per hour, the paper consumption per hour is 160 customers, and the water consumption is 380kg/h. The general size of the egg tray is 30*30cm, and the depth of the egg tray is 46mm. In addition, If the size of the egg tray produced is different from this, it can support custom egg tray molds.

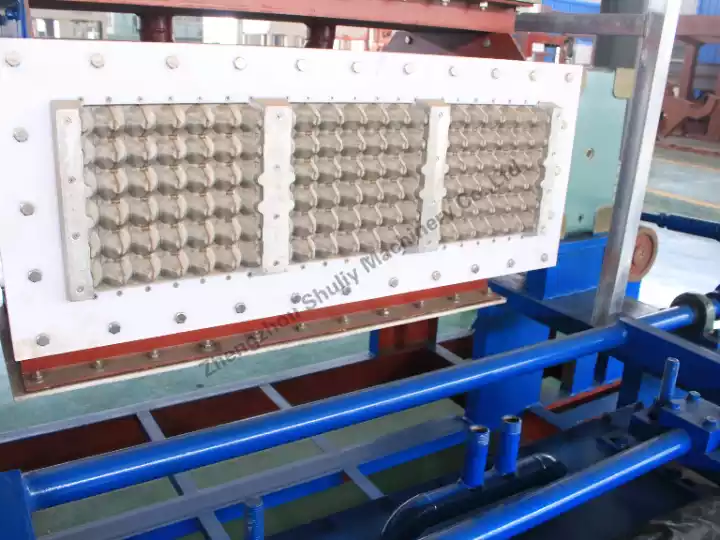

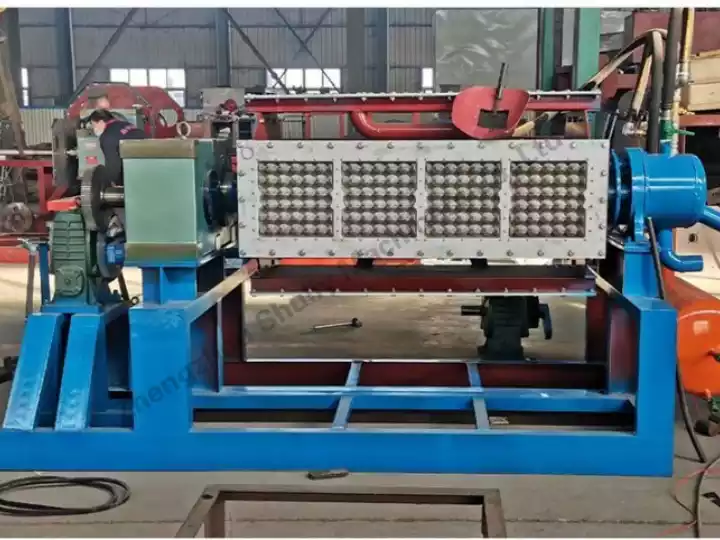

The structure of the egg tray forming machine

This 1500pcs/h egg tray forming machine is an egg tray machine with model SL-4*1, which means that the machine has one egg tray mold, and one side can produce 4 egg trays at a time. This structure improves the production efficiency of the egg tray. The company’s small scale egg tray machine is 1000pcs/h, the model is SL-3*1.

How to dry egg trays?

- Dry naturally. After the egg tray is formed, it can be directly placed in the sun to dry naturally. Generally, it can be dried on a good day.

- Own a brick kiln. Self-built brick kilns need a certain site, and the drying efficiency is relatively high. One thousand pieces of 25m-30m

- Metal dryer. Metal dryers are divided into single-layer dryers and double-layer multi-layer dryers. Multi-layer dryers save space. Also saves more fuel.

How to buy the 1500pcs/h egg tray forming machine?

- Decide if you want to enter the egg tray production industry. You can do your research first, or learn about the egg tray production industry first

- Decide to buy the output of the machine. The scale of production is an indicator that must be clear.

- Learn about the egg tray production process. Consider what equipment is needed for your egg tray production. For example, you can use machine drying for egg tray drying, or you can build your brick kiln.

- You also need to understand the material of the machine. Egg tray machines made of high-quality materials have a longer service life.

Our service about egg tray forming machine

- Design plant site planning drawings. We can plan the location of the egg tray forming machine for the customer according to the production characteristics of the customer and list the main points of the factory

- Send details. The production data of the egg tray forming machine can be provided to the customer before the contract is signed, and the production video of the egg tray forming machine can also be sent

- Assist in production. Professional and technical personnel can provide free online production questions and answers, and know the production and installation production technology to ensure normal production.