How to choose egg tray production equipment?

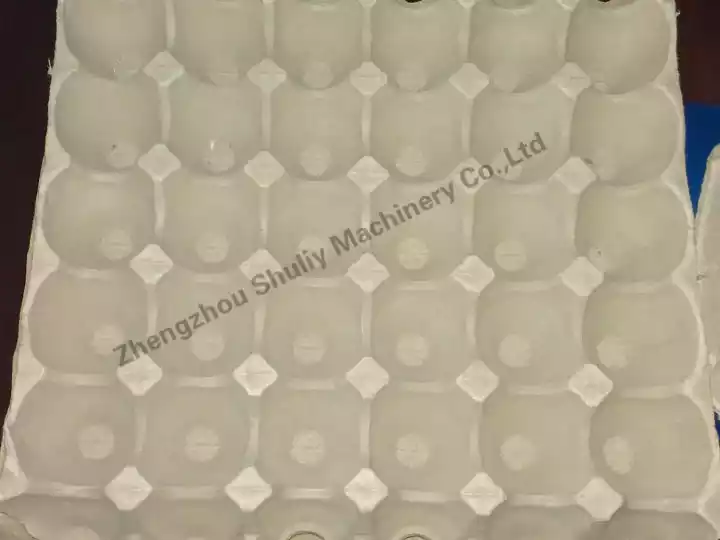

Egg tray production equipment is a machine for processing egg trays, a complete egg tray production line includes a pulper, egg tray forming machine, hot pressing forming machine, and packing machine. There are many producers who want to buy egg tray machines but don’t know how to choose them. The following summarizes the purchase method and precautions for the purchase of the egg tray machine.

How to choose egg tray production equipment

1. When choosing an egg tray machine, the intermittent divider of the main machine is the core component, which directly determines the service life of the egg tray machine and the quality of the formed egg tray products. When purchasing equipment, pay attention to whether the divider equipped with the main engine of the egg tray machine is produced by a famous brand factory.

2. The dehydration system of the egg tray molding machine directly determines the dehydration effect of the egg tray. At the same time, the dehydration system achieves the sealing effect through the frictional contact between the moving ring and the static ring. Wear-resistant materials must be selected, and the connected pipes must be durable. If the quality is not good enough, it will age and leak for a long time, which will directly affect the dehydration effect of the egg tray and increase the drying cost in the later stage.

3. It is also very important to choose egg tray drying equipment. You can choose a suitable egg tray drying equipment according to the heat source and venue used for drying. If it is natural gas, liquefied gas, steam, gas, etc. Energy-saving multi-layer drying; if it is burning coal, wood, and biomass particles, you can choose a durable civil brick kiln for drying.

4. Fourth, the material of the egg tray equipment is also very critical. For example, the contact surface of the pulp with corrosion is made of stainless steel, and the high-temperature area of the drying is made of 316L stainless steel of the refractory brick machine. The screen of the pulper and the dragon piece of the pulper is made of wear-resistant materials such as manganese steel or stainless steel.

How to perform routine maintenance?

During the operation of the egg tray machine equipment, it is inevitable to contact with water, which requires more maintenance of the egg tray machine to prolong its service life. In mild cases, wipe with a sponge or cloth dipped in alcohol, volatile oil, Dina, alcohol, and a mixture of toluene or acetone. Because the egg tray machine shapes the pulp and absorbs the pulp in the pulp tank, the pulp around the egg tray machine will be stained with pulp.

These need to be cleaned in time, not only to ensure the cleanliness of the egg tray machine but if there is too much pulp accumulated The residue can wear down the machine. Do not use hard steel wire balls, chemical agents, or steel brushes when cleaning egg tray production equipment. Use a soft towel, a soft cloth with water, or a neutral detergent, otherwise, it will cause scratches or erosion.