Egg tray carton hot pressing machine

| Name | egg tray hot press machine for shape correction |

| Dimension | 1200*800*1800mm |

| Working Pressure | 15 Tons |

| power | 6.5KW |

| Working Temperature | 160~200℃ |

| Working Cycle Time | 6-10 second |

| Compressed air required | 0.5~0.6MPa, 1M3/min |

| Control | PLC control |

You can now ask our project managers for technical details

An egg tray carton hot pressing machine is a machine for smoothing the surface of egg trays and egg trays, and for deep processing of egg trays. It is generally used for hot pressing after the forming box of the egg tray forming machine, and it can be packaged after the hot pressing.

The heat press only takes 6-10 seconds to press an egg tray, with extremely high production efficiency. At present, the hot press shaping machine has been sold to the United States, France, Vietnam, the Philippines, and other places.

Working video of egg tray hot press

Which products must be shape corrected?

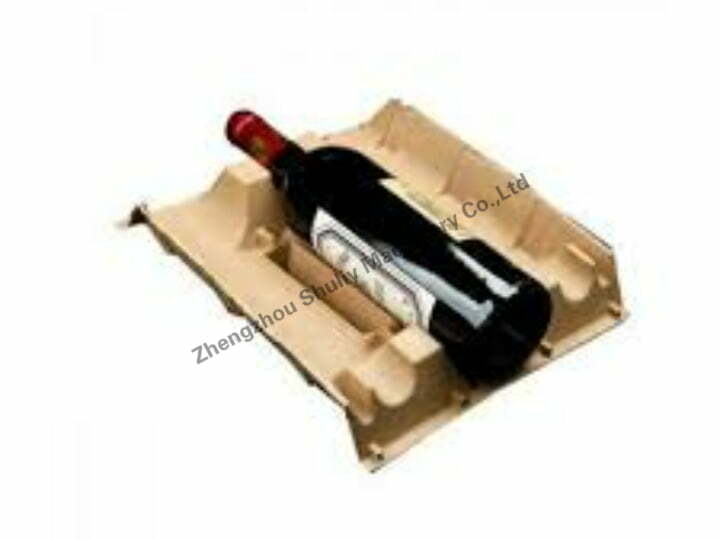

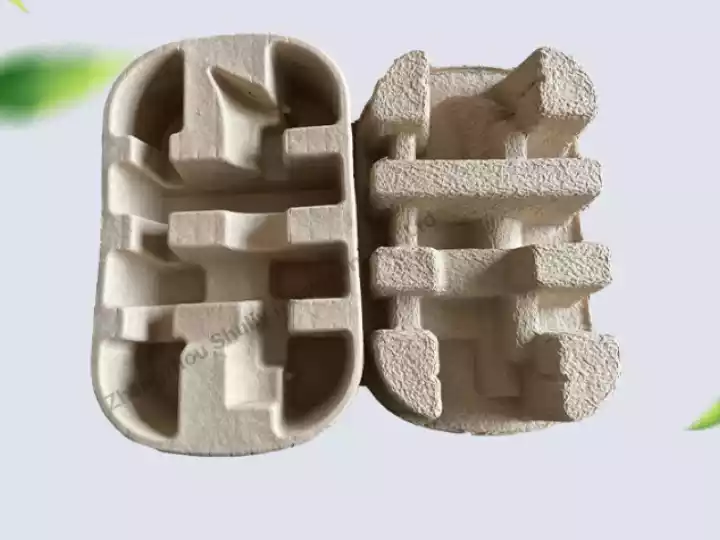

Premium egg trays and other paper products require hot pressing machines. If the requirements for the appearance of the egg tray are not very high, the egg tray can be omitted, but other paper products need to be equipped with a hot pressing machine, such as egg boxes, fruit trays, wine trays, and coffee drink trays.

The function of the egg tray pressing machine

The hot press is used for shape correction after the egg tray is formed, which can make the surface of the egg tray or paper tray smoother. After using the hot press forming machine, the egg carton will be more beautiful, which can increase the price of the egg carton and produce it for the egg carton bringing higher profits.

How to use the egg tray hot pressing machine?

An egg carton hot pressing machine is a semi-automatic machine that needs to be manually operated. By hot pressing the machine, the surface of the egg carton and egg tray is more even. The temperature can be adjusted between 150-200 degrees Celsius according to actual needs.

It has a wide range of applications, which can be used to heat press egg cartons, wine trays, fruit trays, and other paper trays. The time required to hot press an egg tray is 6-10 seconds. Production efficiency is very high.

How an egg carton hot pressing machine works

The egg tray heat press is formed by high temperature. When the surface of the egg carton is exposed to high temperature, the folds on the surface will become stretched, just like ironing clothes at home, which uses the same working principle. The temperature of the egg tray hot pressing machine can also be adjusted, which is very simple and convenient.

The structure of the hot press shaping machine

The core components of the egg tray hot pressing machine include the engine, gear, motor, bearing, gearbox, etc. The main component is the motor. The mold of the egg tray hot press can be replaced, and different molds need to be replaced to process different paper trays.

Advantages of the egg tray pressing machine

- Simple operation, one person can complete the egg tray hot pressing work.

- The machine is equipped with a counter device, which is easy to operate.

- With an infrared safety device.

- With upper and lower mold blowing functions.

Parameters of the hot press forming machine

| Name | egg tray hot press machine for shape correction |

| Dimension | 1200*800*1800mm |

| Working pressure | 15 tons |

| Power | 6.5kw |

| Working temperature | 160~200℃ |

| Working cycle time | 6-10 second |

| Compressed air required | 0.5~0.6mpa, 1m³/min |

| Control | PLC control |

FAQ

What is the function of an egg tray hot press machine?

It is used to press molded pulp egg trays at high temperatures to make them smoother, harder, and more water-resistant, improving appearance and durability.

Can the machine be used for trays other than egg trays?

Yes, by changing the mold, it can be used for fruit trays, bottle trays, cup holders, and other molded pulp products.

Does hot pressing increase tray strength?

Yes, it compacts the fiber structure, improving mechanical strength, waterproofing, and resistance to deformation.

Can I customize the mold shape and logo?

Yes, we can produce molds with your desired tray shape, cell size, and embossed logo.

Does my egg tray production line need to be equipped with a hot press machine?

Not necessarily. A hot press machine is optional equipment. However, egg trays that have been hot pressed look better and can command a higher price.

Contact us!

If you would like to learn more about egg tray hot press machines, videos, or quotes, please feel free to contact us.