Paper wine tray-making machine | molded pulp packaging machine

| model | SL-4*4 |

| capacity | 3000-3500pcs/h |

| paper consumption | 280kg/h |

| Water Consumption | 560kg/h |

| energy used | 78kw/h |

| worker | 4-5 |

You can now ask our project managers for technical details

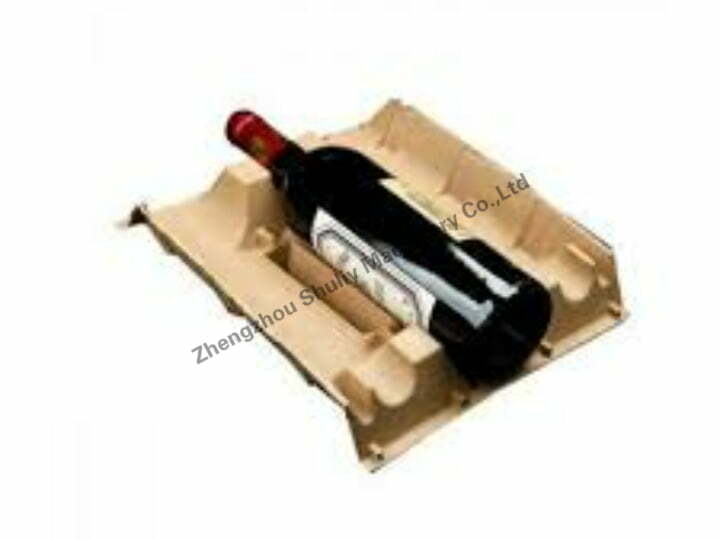

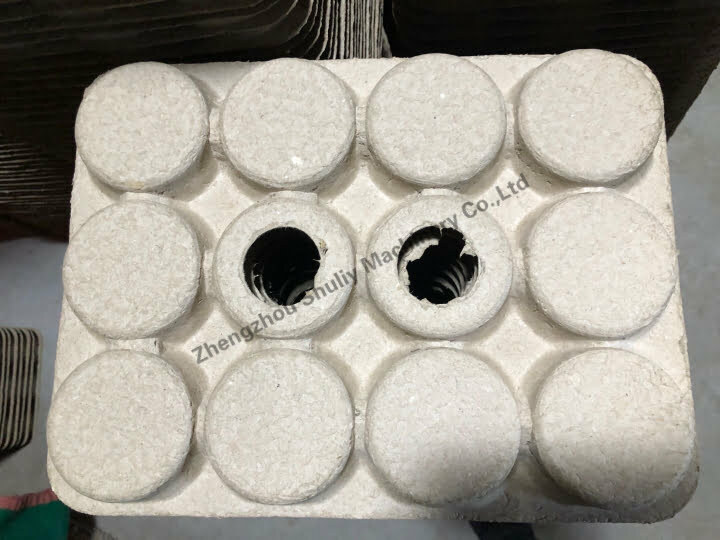

The paper wine tray-making machine is a kind of paper tray for wine bottle packaging. The wine tray production machine uses waste paper to perform processes such as crushing, molding, drying, etc., to produce the packaging of wine bottles to prevent glass products from hitting and breaking. This paper wine tray-making machine can Production of egg trays, nursery trays, apple trays, and other products. The machine has been sold to Canada, Nigeria, Saudi Arabia, Oman, South Africa, and more.

Why egg tray machine can produce a wine tray

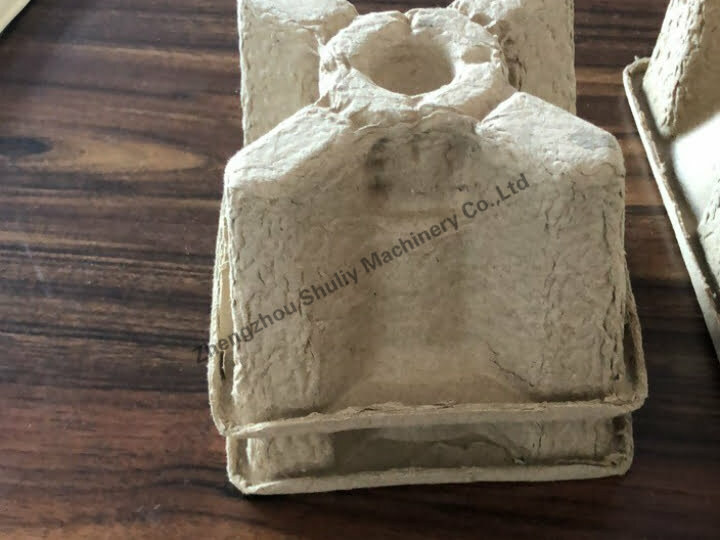

Because the molds produced by the egg tray machine can be replaced, different shapes of packaging can be produced by changing different molds. This is also the reason for the diversity of functions of the egg tray machine. If you need to order a wine tray for your winery machine to produce the packaging of red wine, then you only need to provide the size of the wine bottle, and you can customize a unique machine.

Paper wine tray production process

1. Pulping system Of paper wine tray-making machine

(1) Put the raw material into the pulping machine, add an appropriate amount of water, stir it for a long time to turn the waste paper into pulp, and then put it into the pulp storage tank for storage.

(2) Put the pulp in the pulp storage tank into the pulp mixing tank, adjust the pulp concentration in the pulp mixing tank, and further stir through the white water in the return tank and the thick pulp in the pulp storage tank through the homogenizer. After adjusting to a suitable pulp, put it into the pulp supply tank to be used in the forming system.

Equipment used: pulper, homogenizer, pulp pump, vibrating screen, pulp decompressor

2. Forming a system

(1) The pulp in the pulp supply tank is fed into the forming machine, and adsorbed by the vacuum system, the pulp is passed through the mold on the equipment, and the pulp is left on the mold to form, and the white water is adsorbed and transferred back to the water tank by the vacuum pump.

(2) After the mold is adsorbed, the transfer mold passes through the positive pressure of the air compressor to discharge the air, and the molded product is blown from the molding mold to the rotating mold, and some are sent out by the transfer mold.

Equipment used: molding machine, mold, vacuum pump, negative pressure tank, water pump, air compressor, mold cleaning machine

3. Drying system

(1) Natural drying method: directly rely on the weather and natural wind to dry the product.

(2) Traditional drying: brick-built tunnel kiln, the heat source can choose natural gas, diesel, coal, dry wood, heat sources such as liquefied petroleum gas.

(3) New multi-layer drying line: 6-layer metal drying line can save energy by more than 30% compared with transmission drying, and the main heat source is natural gas, diesel oil, and liquefied petroleum gas.

4. Auxiliary packaging of finished products

(1) Automatic stacker

(2) Baler

The equipment and technological processes used in the production of wine trays are the same as those of egg trays. The production is relatively simple, and there are many types of paper wine tray-making machines The minimum output is a paper wine tray-making machine 1000pc/h.