Línea de producción automática de bandejas de huevos de papel.

| modelo | SL-4*4 |

| producto | bandeja de huevos |

| capacidad | 3000-3500 piezas/h |

| consumo de papel | 280kg/hora |

| Consumo de agua | 560kg/hora |

| energía utilizada | 78 kw/h |

| numero de trabajador | 4-5 |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

La línea de producción automática de bandejas de huevos de papel es un dispositivo utilizado para producir bandejas de huevos. La máquina de bandejas de huevos utiliza papel de desecho para fabricar bandejas de huevos, lo cual es un producto muy respetuoso con el medio ambiente.

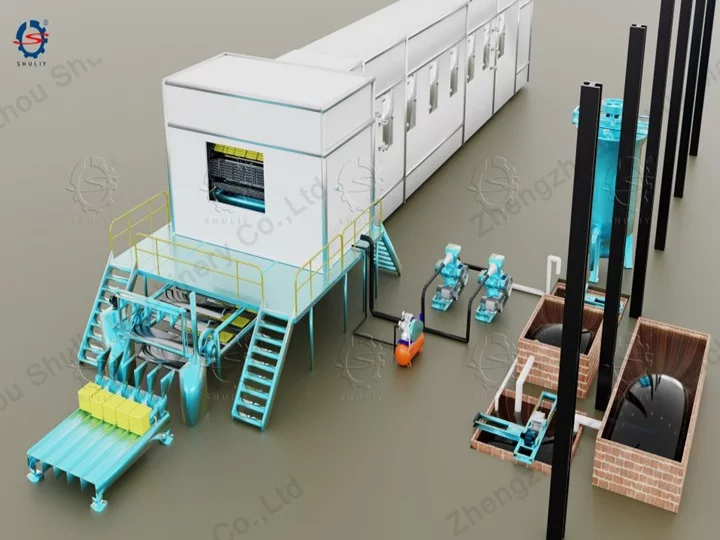

La línea de producción de bandejas de papel para huevos incluye principalmente la parte de pulpa, la parte de formación de bandejas de huevos, la parte de secado y la parte de embalaje. La producción de la línea de producción de bandejas de papel de Shuliy es de 1000-8000pcs/h.

¿Cómo funciona la línea de producción de bandejas de huevos de papel?

Proceso automático de línea de producción de bandejas de huevos de papel

Pulpa de bandejas de huevos

La producción de la línea de producción de bandejas de papel para huevos necesita construir tres estanques, que se utilizan para la pulpa, almacenamiento de pulpa y un estanque de almacenamiento de agua, respectivamente. El equipo requerido es un pulper hidráulico. Necesita ser agitado durante casi 40 minutos.

El proceso de producción específico es pulverizar el papel reciclado a través de un pulper, agregar agua y transportarlo al tanque de almacenamiento de pulpa, y luego poner la pulpa en el tanque de almacenamiento de pulpa en el tanque de mezcla de pulpa para ajustar la concentración de la pulpa, que se puede usar. El homogeneizador agita la pulpa uniformemente.

La pulpa con buena consistencia se puede introducir en el tanque de suministro de pulpa para su procesamiento. La estructura de la máquina despulpadora incluye varias partes: máquina despulpadora, homogeneizador, bomba de pulpa, criba vibratoria y máquina desintegradora de pulpa.

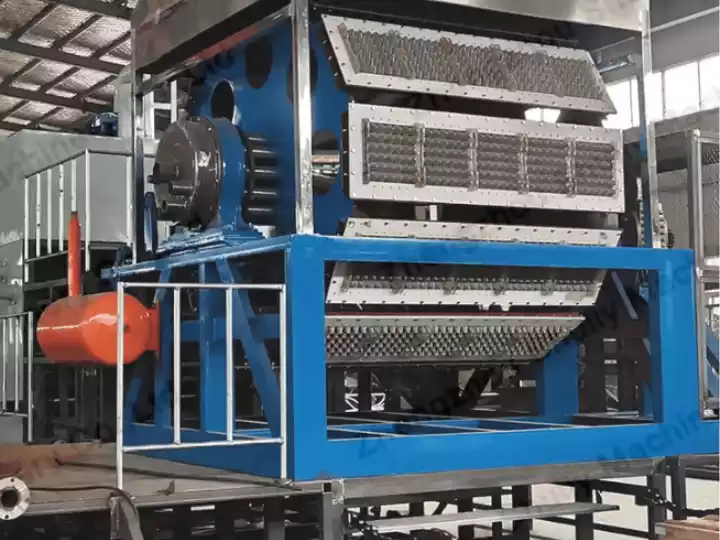

Formando bandejas de huevos

El moldeo se divide simplemente en dos pasos. En el primer paso, la pulpa en el tanque de suministro de pulpa se adsorbe en el molde a través del sistema de adsorción al vacío. Después de que el molde se adsorbe, se transfiere al molde para formar la forma de la bandeja de huevos.

En el segundo paso, la bandeja de huevos adsorbida en el molde se transfiere al sistema de transferencia a través del compresor de aire, y la máquina puede ser retirada automáticamente.

La estructura de la máquina formadora de bandejas de huevos incluye una máquina formadora de bandejas de huevos, molde, bomba de vacío, tanque de presión negativa, bomba de agua, compresor de aire y máquina de limpieza de moldes.

Secado de bandejas de huevos

Los métodos de secado de bandejas de huevos se dividen en secado natural, secado en horno de ladrillo y secado en secadora. El método de secado se determina según la producción y el clima local. Con la secadora de bandejas de papel, las bandejas de huevos se pueden secar en poco tiempo.

Conformación en caliente

La bandeja de huevos preparada se llena de agua cuando acaba de terminar, pero después de secarse, la humedad se reduce, y la superficie de la bandeja de huevos dejará algunas arrugas, lo que afecta su uso. Pero si deseas que la superficie sea más suave, entonces necesitas ser prensada en caliente con una máquina formadora de prensado en caliente. Y la bandeja de huevos formada será más hermosa.

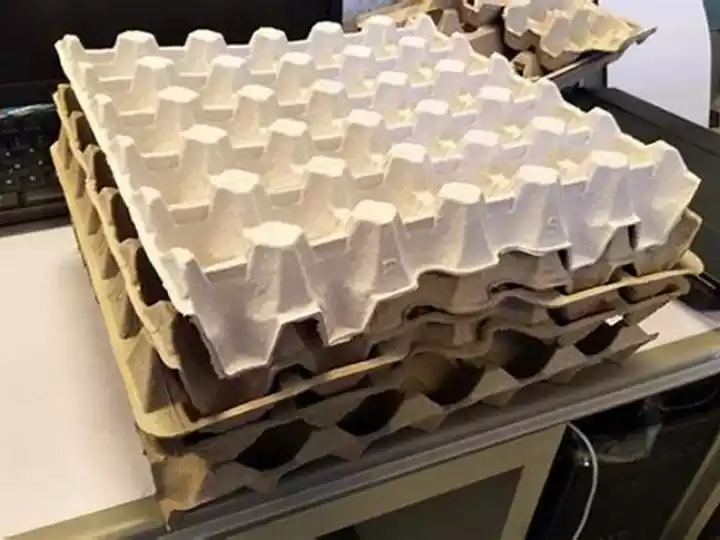

Embalaje de bandeja de huevos

El envasado es el último paso de la línea de producción de bandejas de pulpa para huevos. La máquina empacadora de bandejas de huevos puede apilar varias bandejas de huevos muy juntas.

Parámetros de la máquina de bandeja de huevos

| Modelo | Capacidad | Consumo de papel | Consumo de agua | Energía utilizada | Obrero |

| SL-3*1 | 1000-1500 unidades/h | 120kg/hora | 300kg/h | 32 kw/h | 3-4 |

| SL-4*1 | 1500-2000PCS/h | 160kg/hora | 380kg/h | 45kw/h | 3-4 |

| SL-3*4 | 2000-2500 piezas/h | 200kg/h | 450kg/h | 58 kw/h | 4-5 |

| SL-4*4 | 3000-3500 piezas/h | 280kg/hora | 560kg/hora | 78 kw/h | 4-5 |

| SL-4*8 | 4000 piezas/h | 320kg/h | 600kg/hora | 80 kw/h | 5-6 |

| SL-5*8 | 5000 piezas/hora | 400kg/h | 750kg/hora | 85 kw/h | 3-4 |

| SL-6*8 | 6000 piezas/h | 480kg/h | 900kg/hora | 90 kw/h | 3-4 |

| SL-8*8 | 8000 piezas/hora | 640kg/hora | 1040kg/hora | 100 kw/h | 3-4 |

Ya sea que estés buscando equipos de producción de bandejas de huevos de pequeña capacidad o una máquina de bandejas de huevos de gran capacidad. Podemos satisfacer tus necesidades. Tenemos la máquina con salidas de 1000pcs/h-8000pcs/h para que elijas.

Ventajas de la línea de producción de bandejas de papel para huevos

- Sin contaminación, el proceso de producción de bandejas de huevos no tiene contaminación ambiental, pero pertenece a la industria de utilización de recursos reciclados.

- Bajo costo porque la materia prima es papel usado, el costo es bajo

- Producción totalmente automatizada, ahorrando mano de obra. Todo el proceso de producción de bandejas de huevos solo necesita 3-4 personas

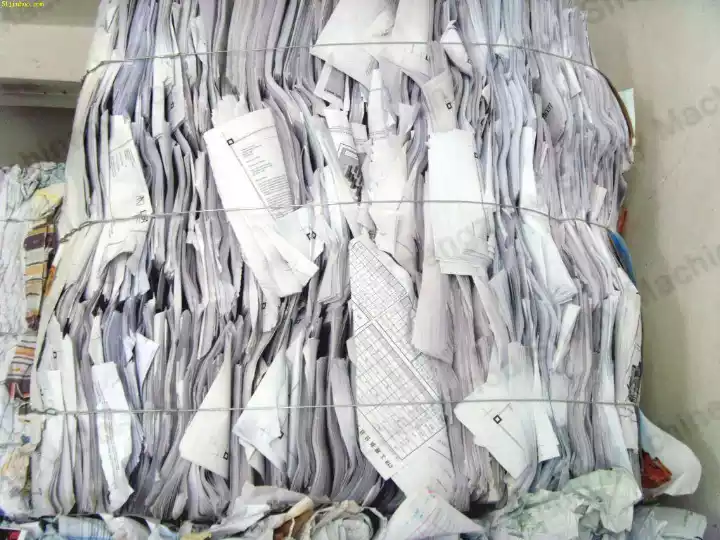

¿Qué materias primas se pueden utilizar para producir la línea de producción de bandejas de huevos de papel?

La producción de bandejas de huevos puede utilizar cartones de desecho, libros de desecho, impresión en papel A4 o bandejas de huevos de desecho para reciclaje. Por tanto, las materias primas para la producción de bandejas de huevos son muy amplias.

Vídeo 3D de la línea de producción de bandejas de huevos de papel.

¿Por qué es bienvenida la máquina para bandejas de huevos?

Después de las estadísticas, se ha encontrado que las ventas de máquinas de bandejas de huevos están en constante aumento. Durante el proceso de conexión con los clientes, encontramos que hay tres razones principales por las que fabrican máquinas de bandejas de huevos.

Primero que nada, la máquina de bandejas de huevos pertenece a la industria de reciclaje de recursos, que es muy ecológica y también es apoyada por el gobierno local.

En segundo lugar, las materias primas de la línea de producción de bandejas de papel para huevos son fáciles de obtener. Las materias primas utilizadas por la máquina de bandejas de huevos son principalmente papel reciclado, que se puede recolectar fácilmente en muchos países.

Finalmente, por supuesto, es muy fácil vender bandejas de huevos. Las gallinas tienen una gran demanda de bandejas de huevos, y estos son consumibles, por lo que es fácil de fijar para los clientes. Muchas personas están dispuestas a elegir producir bandejas de huevos y obtener ganancias por ello.

¿Cuál es el proceso de despulpado de la bandeja de huevos?

La pulpa principalmente necesita controlar la proporción de agua y pulpa. En términos generales, la proporción de agua y pulpa es 1:3 y se mezcla uniformemente. Se necesita agregar una cierta cantidad de pegamento o agua de cal en el proceso, lo que puede hacer que la bandeja de huevos sea más firme. Estos son generalmente los trabajos que necesitan hacerse en la forma de bandejas de huevos.

- Las bandejas de huevos se producen utilizando papel reciclado, y su calidad está, por supuesto, estrechamente relacionada con las materias primas.

- También está relacionado con la máquina, la bandeja de huevos producida por una máquina de buena calidad es más resistente.

- Por otro lado, también está relacionado con la tecnología de producción. La producción de bandejas para huevos también tiene muchos puntos de habilidad, como la proporción de pulpa y la cantidad de aditivos, que deben calcularse sin realizar experimentos.

Arreglo de empleo de la línea de producción de bandejas de papel para huevos

El proceso de producción de bandejas de huevos se comprende probablemente, entonces, ¿cuánta mano de obra necesitas normalmente para construir una industria completa de bandejas de huevos? Después de experimentos, se encontró que solo se necesitaban 4 trabajadores: se requería un trabajador para la pulpa de bandejas de huevos, un trabajador para el moldeo de bandejas de huevos, un trabajador para el procesamiento secundario de bandejas de huevos prensadas en caliente, y un trabajador para el embalaje.

Servicio de Shuliy

- Introducción detallada al proceso de producción de bandejas de huevos en preventa, recorrido en vídeo por la fábrica

- Diseñe la ubicación de la máquina y proporcione instrucciones de instalación gratuitas en línea

- Los problemas de servicio postventa se resuelven en línea, y los problemas técnicos en el proceso de producción pueden ser ayudados a responder.

Preguntas frecuentes

¿Cuál es la capacidad de producción de la máquina de bandejas de huevos?

De 1.000 a 8.000 piezas/h, dependiendo del modelo y del sistema de secado.

¿Qué tipos de bandejas de huevos puede producir?

Bandejas de huevos de 30 celdas, cajas de huevos, bandejas de frutas, portavasos y otros productos moldeados de pulpa (cambiando los moldes).

¿Se pueden personalizar los moldes?

Sí. Los moldes de aluminio o plástico se pueden personalizar según el diseño de su bandeja.

¿Proporcionan servicio de instalación y postventa?

Sí. Ofrecemos diseño de distribución, guía de instalación en línea, capacitación, suministro de piezas de repuesto y soporte de ingenieros si es necesario.

¡Comience su negocio de bandejas de huevos hoy!

Contacte con nuestro equipo de ingeniería profesional para una evaluación y cotización gratuitas del proyecto — le ayudaremos a diseñar una planta de producción de bandejas de huevos rentable adaptada a su suministro de materia prima, capacidad y presupuesto.