Is Wine Tray Production line Profitable?

The global wine industry is undergoing a massive transformation. It’s not just about the vintage; it’s about the packaging. With increasing global bans on single-use plastics and Styrofoam (EPS), wineries are scrambling for eco-friendly alternatives to protect their fragile bottles during transit.

This shift has created a golden opportunity for manufacturers: Molded Pulp Wine Trays. But for investors and entrepreneurs, the burning question remains: Is wine tray production actually profitable?

In this post, we analyze the raw material costs and market potential to help you decide if investing in a Wine Tray Making Machine is the right move for your business.

Market Analysis: Why Demand is Exploding

The demand for paper pulp wine trays is driven by two main factors: Regulation and Consumer Preference.

- Global plastic bans: major markets like the EU, Canada, and parts of the USA are phasing out expanded polystyrene (EPS) foam. Wineries must switch to biodegradable options.

- Premium branding: molded pulp looks more premium and “natural” than white foam. High-end wine brands prefer paper trays because they align with the organic and sustainable image of their products.

The opportunity: the supply of high-quality, heavy-duty paper wine trays is currently struggling to keep up with the demand from vineyards and logistics companies. This supply gap means higher profit margins for early producers.

Cost Analysis: Turning Waste into Wealth

The biggest advantage of the pulp molding business is the incredibly low cost of raw materials.

- Raw material: the primary ingredient is waste paper (old newspapers, carton boxes, A4 paper, or scraps from printing factories). In many regions, this material can be acquired very cheaply or even for free.

- Additives: only minor amounts of waterproofing agents are needed, keeping chemical costs negligible.

- Process: the process mainly involves water and electricity (or gas/diesel for drying).

The math is simple:

You take low-value waste paper→ Process it through a Molded Pulp Machine→ Sell high-value, eco-friendly wine packaging.

The value-added gap between a ton of waste paper and a ton of finished wine trays is significant, ensuring a quick Return on Investment (ROI).

What Makes a Good Wine Tray?

Unlike simple egg trays, wine trays require higher precision and strength. A wine bottle is heavy and fragile; the tray must absorb shocks perfectly.

This is where the equipment matters. You cannot produce premium wine trays with an outdated machine. You need a modern Wine Tray Making Machine (also known as an Industrial Package Pulp Molding Machine) that offers:

- Precision molds: to ensure the bottle fits snugly without movement.

- High pressure: to pack the fibers tightly for maximum load-bearing capacity.

- Smooth surface: to prevent scratching the wine labels.

Why Choose Our Wine Tray Making Machine?

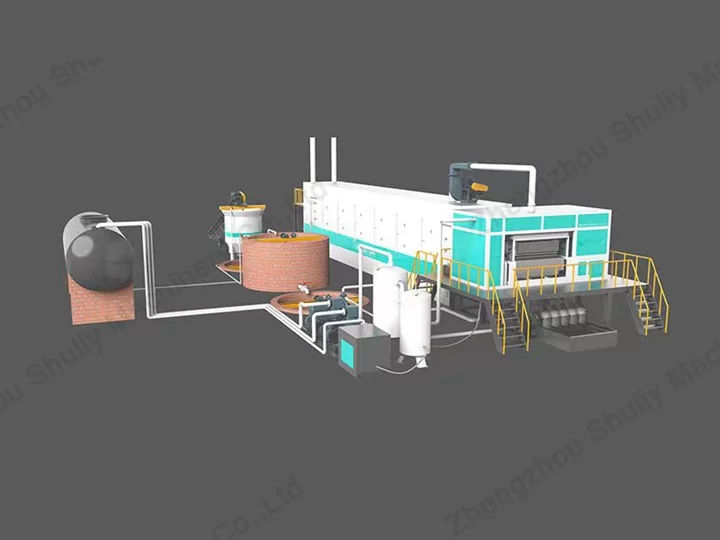

At Shuliy, we specialize in turning waste paper into profit. Our Pulp Molding Machines are engineered specifically for high-value industrial packaging, including wine trays, electronic packaging, and medical trays.

Key features of our machine:

- Versatility: our machine isn’t just for wine. By simply changing the molds, you can produce egg cartons, fruit trays, or coffee cup holders, diversifying your income streams.

- Energy efficiency: our latest drying system recycles heat, reducing fuel consumption by up to 30% compared to traditional models.

- Customizable molds: whether your clients need trays for 1, 2, 6, or 12 bottles, our CNC-processed molds ensure perfect dimensions every time.

- Full automation: from pulping to drying and stacking, our automated lines reduce labor costs, allowing you to scale up production effortlessly.

Conclusion

The transition to sustainable packaging is not a trend; it is the future standard. With low raw material costs and a global market hungry for eco-friendly solutions, wine tray production is one of the most profitable ventures in the packaging industry today.

Don’t let this opportunity pass. Equip your factory with a reliable, high-efficiency Wine Tray Making Machine.