خودکار کاغذ انڈے کی ٹرے کی پیداواری لائن

| ماڈل | SL-4*4 |

| مصنوعات | انڈے کی ٹرے |

| صلاحیت | 3000-3500 ٹکڑے فی گھنٹہ |

| کاغذ کی کھپت | 280 کلوگرام فی گھنٹہ |

| پانی کی کھپت | 560 کلوگرام فی گھنٹہ |

| استعمال کی جانے والی توانائی | 78 کلو واٹ فی گھنٹہ |

| ورکر نمبر | 4-5 |

آپ اب ہمارے پروجیکٹ منیجرز سے تکنیکی تفصیلات پوچھ سکتے ہیں

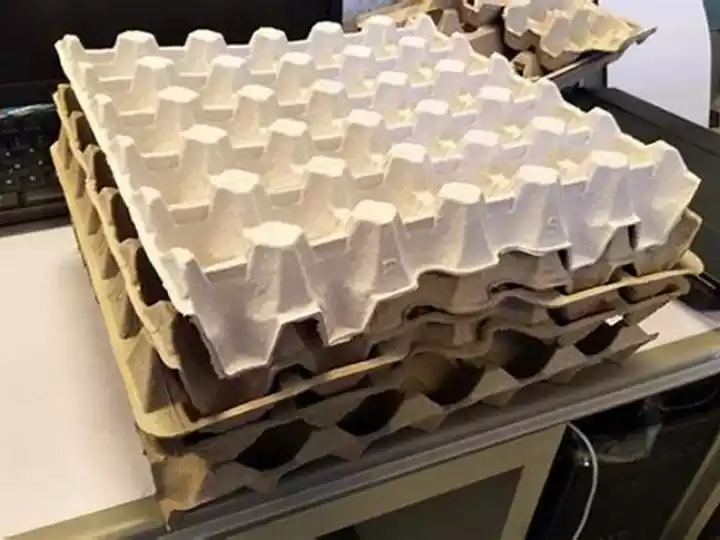

خودکار پیپر انڈہ ٹرے پیداوار لائن ایک ایسا آلہ ہے جو انڈہ ٹرے بنانے کے لیے استعمال ہوتا ہے۔ انڈہ ٹرے مشین فضلے کے کاغذ سے انڈہ ٹرے بناتی ہے، جو کہ ایک بہت ماحول دوست مصنوعات ہے۔

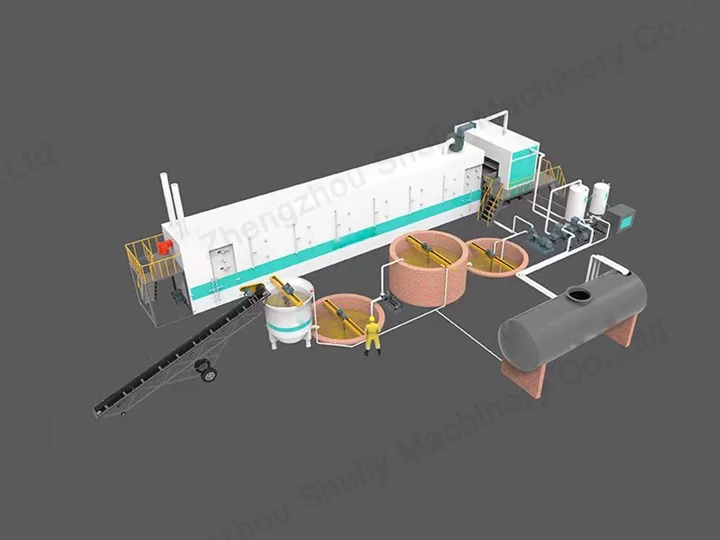

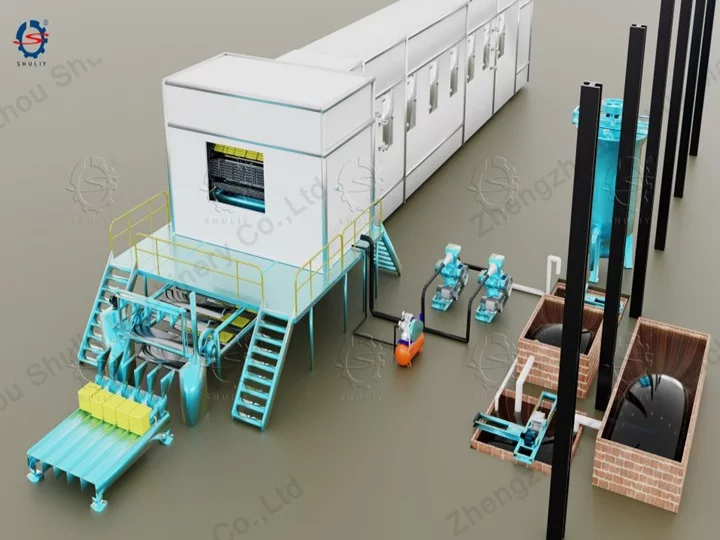

کاغذی انڈہ ٹرے پیداوار لائن میں بنیادی طور پر پُولپنگ حصہ، انڈہ ٹرے بنانے کا حصہ، خشک کرنے کا حصہ، اور پیکنگ کا حصہ شامل ہے۔ شولیو کی کاغذی انڈہ ٹرے پیداوار لائن کی پیداوار 1000-8000 ٹکڑے فی گھنٹہ ہے۔

کاغذی انڈے کی ٹرے کی پیداوار کی لائن کیسے کام کرتی ہے؟

خودکار کاغذ انڈہ ٹرے پیداوار لائن کا عمل

انڈہ ٹرے پلسنگ

کاغذی انڈہ ٹرے پیداوار لائن کی پیداوار کے لیے تین پول بنانا ضروری ہے، جو کہ پُولپنگ، پُولپ اسٹوریج، اور پانی کے اسٹوریج پول کے لیے استعمال ہوتے ہیں۔ ضروری آلات میں ہائیڈرولک پُولپر شامل ہے۔ اسے تقریباً 40 منٹ تک ہلچل مچانی ہوتی ہے۔

خاص پیداوار کا عمل یہ ہے کہ فضلے کے کاغذ کو پُولپر کے ذریعے پیسا جاتا ہے، پانی شامل کیا جاتا ہے، اور اسے پُولپ اسٹوریج ٹینک میں لے جایا جاتا ہے، پھر پُولپ کو پُولپ مکسنگ ٹینک میں ڈال کر کنسنٹریشن کو ایڈجسٹ کیا جاتا ہے، تاکہ استعمال کے قابل ہو۔ ہوموجینائزر پُولپ کو یکساں ہلاتا ہے۔

اچھی مستقل مزاجی کے ساتھ گودا پروسیسنگ کے لیے گودے کی فراہمی کے ٹینک میں داخل کیا جا سکتا ہے۔ گودا بنانے کی مشین کی ساخت میں کئی حصے شامل ہیں: گودا بنانے کی مشین، ہم آہنگ کرنے والی مشین، گودا پمپ، کمپن کرنے والی اسکرین، اور گودا توڑنے والی مشین۔

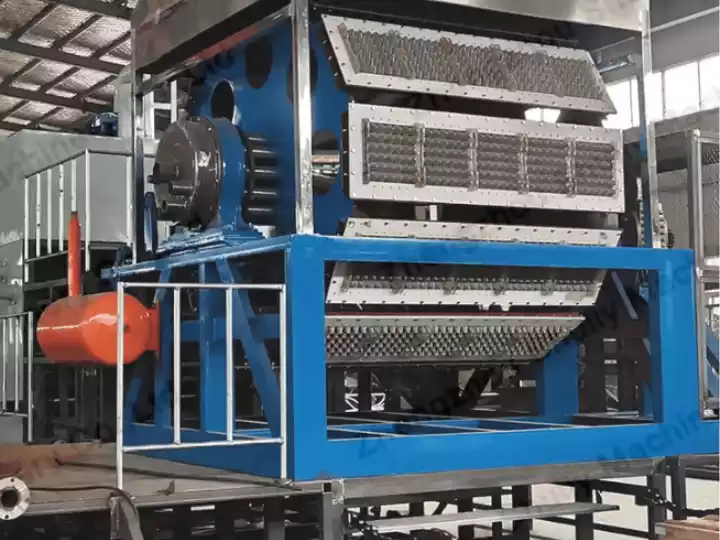

انڈے کے ٹرے کی تشکیل

مولڈنگ کو آسانی سے دو مراحل میں تقسیم کیا جا سکتا ہے۔ پہلے مرحلے میں، پُولپ سپلائی ٹینک میں موجود پُولپ کو ویکیوم جذب نظام کے ذریعے مولڈ پر جذب کیا جاتا ہے۔ مولڈ کے جذب ہونے کے بعد، اسے انڈہ ٹرے کی شکل بنانے کے لیے منتقل کیا جاتا ہے۔

دوسرے مرحلے میں، انڈہ ٹرے جو مولڈ پر جذب ہوا ہے، اسے ہوا کے compressor کے ذریعے ٹرانسفر سسٹم میں منتقل کیا جاتا ہے، اور مشین خودکار طور پر ہٹا دی جاتی ہے۔

انڈہ ٹرے بنانے والی مشین کی ساخت میں انڈہ ٹرے بنانے والی مشین، مولڈ، ویکیوم پمپ، منفی دباؤ کا ٹینک، پانی کا پمپ، ہوا کا compressor، اور مولڈ صفائی مشین شامل ہیں۔

انڈے کے ٹرے کو خشک کرنا

The drying methods of egg trays are divided into natural drying, brick kiln drying, and dryer drying. The drying method is determined according to the output and local climate. With the paper egg tray dryer, the egg trays can be dried in a short time.

گرم دباؤ کی تشکیل

تیار شدہ انڈہ ٹرے کو ابھی مکمل ہونے کے بعد پانی سے بھر دیا جاتا ہے، لیکن خشک ہونے کے بعد، نمی کم ہو جاتی ہے، اور انڈہ ٹرے کی سطح پر کچھ جھریاں پڑ جاتی ہیں، جو اس کے استعمال کو متاثر کرتی ہیں۔ اگر آپ چاہتے ہیں کہ سطح زیادہ ہموار ہو، تو آپ کو ہاٹ پریس فارمنگ مشین کے ساتھ گرم پریس کرنا ہوگا۔ اور بنے ہوئے انڈہ ٹرے زیادہ خوبصورت نظر آئیں گے۔

انڈے کی ٹرے پیک کرنا

پیکیجنگ گودے کی انڈے کی ٹرے کی پیداوار کی لائن کا آخری مرحلہ ہے۔ انڈے کی ٹرے کی پیکیجنگ مشین کئی انڈے کی ٹریوں کو ایک ساتھ مضبوطی سے سٹیک کر سکتی ہے۔

انڈے کی ٹرے مشین کے پیرامیٹرز

| ماڈل | صلاحیت | کاغذ کی کھپت | پانی کی کھپت | استعمال شدہ توانائی | مزدور |

| SL-3*1 | 1000-1500 پی سیز فی گھنٹہ | 120 کلوگرام فی گھنٹہ | 300kg/h | 32 کلو واٹ فی گھنٹہ | 3-4 |

| SL-4*1 | 1500-2000PCS/گھنٹہ | 160kg/گھنٹہ | 380kg/گھنٹہ | 45kw/گھنٹہ | 3-4 |

| SL-3*4 | 2000-2500 ٹکڑے فی گھنٹہ | 200کلوگرام/گھنٹہ | 450کلوگرام/گھنٹہ | 58 کلو واٹ فی گھنٹہ | 4-5 |

| SL-4*4 | 3000-3500 ٹکڑے فی گھنٹہ | 280 کلوگرام فی گھنٹہ | 560 کلوگرام فی گھنٹہ | 78 کلو واٹ فی گھنٹہ | 4-5 |

| SL-4*8 | 4000 ٹکڑے فی گھنٹہ | 320 کلوگرام فی گھنٹہ | 600 کلوگرام فی گھنٹہ | 80 کلو واٹ فی گھنٹہ | 5-6 |

| SL-5*8 | 5000 ٹکڑے فی گھنٹہ | 400 کلوگرام فی گھنٹہ | 750 کلوگرام فی گھنٹہ | 85 کلو واٹ فی گھنٹہ | 3-4 |

| ایس ایل-6*8 | 6000 ٹکڑے فی گھنٹہ | 480 کلوگرام فی گھنٹہ | 900 کلوگرام فی گھنٹہ | 90 کلو واٹ فی گھنٹہ | 3-4 |

| ایس ایل-8*8 | 8000 پی سیز فی گھنٹہ | 640 کلوگرام فی گھنٹہ | 1040 کلوگرام فی گھنٹہ | 100 کلو واٹ فی گھنٹہ | 3-4 |

چاہے آپ چھوٹی صلاحیت والی انڈہ ٹرے پیداوار کا سامان تلاش کر رہے ہوں یا بڑی صلاحیت والی انڈہ ٹرے مشین، ہم آپ کی ضروریات کو پورا کر سکتے ہیں۔ ہمارے پاس 1000 ٹکڑے/گھنٹہ سے 8000 ٹکڑے/گھنٹہ تک کی پیداوار والی مشینیں دستیاب ہیں۔

کاغذی انڈہ ٹرے پیداوار لائن کے فوائد

- کوئی آلودگی نہیں، انڈہ ٹرے پیداوار کا عمل ماحولیاتی آلودگی سے پاک ہے، بلکہ یہ ری سائیکل وسائل کے استعمال کی صنعت سے تعلق رکھتی ہے۔

- کم قیمت کیونکہ خام مال استعمال شدہ کاغذ ہے، قیمت کم ہے۔

- مکمل خودکار پیداوار، مزدوری کی بچت۔ پورا انڈہ ٹرے پیداوار کا عمل صرف ضرورت ہے 3-4 افراد

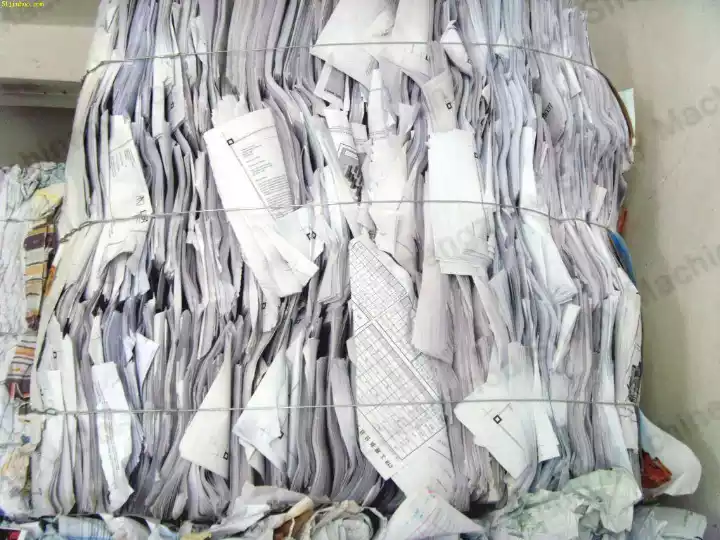

کاغذ کی انڈے کی ٹرے کی پیداوار کی لائن تیار کرنے کے لیے کون سے خام مال استعمال کیے جا سکتے ہیں؟

انڈے کی ٹرے کی پیداوار میں فضول کارٹن، فضول کتابیں، A4 کاغذ کی چھپائی، یا فضول انڈے کی ٹرے کو ری سائیکل کرنے کے لیے استعمال کیا جا سکتا ہے۔ لہذا، انڈے کی ٹرے کی پیداوار کے لیے خام مال بہت وسیع ہے۔

کاغذی انڈے کی ٹرے کی پیداوار لائن کی 3D ویڈیو

انڈے کی ٹرے کی مشین کو کیوں پسند کیا جاتا ہے؟

اعداد و شمار کے مطابق، انڈہ ٹرے مشینوں کی فروخت مسلسل بڑھ رہی ہے۔ صارفین کے ساتھ رابطہ کے دوران، ہمیں پتہ چلا کہ ان کے انڈہ ٹرے مشینیں بنانے کی تین اہم وجوہات ہیں۔

سب سے پہلے، انڈہ ٹرے مشین وسائل کے ری سائیکلنگ صنعت سے تعلق رکھتی ہے، جو کہ بہت ماحول دوست ہے اور مقامی حکومت کی طرف سے بھی حمایت حاصل ہے۔

دوسری بات، کاغذی انڈہ ٹرے پیداوار لائن کے خام مال آسانی سے دستیاب ہیں۔ انڈہ ٹرے مشین کے استعمال میں آنے والا خام مال بنیادی طور پر فضلہ کاغذ ہے، جسے بہت سے ممالک میں آسانی سے جمع کیا جا سکتا ہے۔

آخر میں، انڈہ ٹرے بیچنا بہت آسان ہے۔ مرغیوں کو انڈہ ٹرے کی بہت طلب ہوتی ہے، اور یہ اشیاء استعمال میں آتی ہیں، اس لیے صارفین کے لیے اسے ٹھیک کرنا آسان ہے۔ بہت سے لوگ انڈہ ٹرے بنانے اور منافع کمانے کا انتخاب کرتے ہیں۔

انڈے کی ٹرے کا پلسنگ کا عمل کیا ہے؟

پُولپ کو بنیادی طور پر پانی اور پُولپ کے تناسب کو کنٹرول کرنے کی ضرورت ہوتی ہے۔ عام طور پر، پانی اور پُولپ کا تناسب 1:3 ہوتا ہے اور اسے اچھی طرح مکس کیا جاتا ہے۔ عمل کے دوران، کچھ مقدار میں گلو یا چونے کا پانی شامل کرنا ضروری ہے، تاکہ انڈہ ٹرے زیادہ مضبوط ہو جائے۔ یہ کام عموماً انڈہ ٹرے کی شکل میں انجام دیا جاتا ہے۔

- انڈہ ٹرے فضلے کے کاغذ سے بنائے جاتے ہیں، اور ان کا معیار، ظاہر ہے، خام مال سے بہت قریب سے جُڑا ہوا ہے۔

- یہ مشین سے بھی متعلق ہے، اچھی معیار کی مشین سے تیار کردہ انڈے کی ٹرے زیادہ مضبوط ہوتی ہے۔

- دوسری طرف، یہ پیداوار کی ٹیکنالوجی سے بھی متعلق ہے۔ انڈے کی ٹرے کی پیداوار میں بھی بہت سے مہارت کے نکات ہوتے ہیں، جیسے کہ گودے کا تناسب اور اضافی اشیاء کی تعداد، جنہیں تجربات کیے بغیر حساب کرنا ضروری ہے۔

کاغذی انڈہ ٹرے پیداوار لائن کی ملازمت کا انتظام

انڈہ ٹرے بنانے کے عمل کو شاید سمجھ لیا گیا ہے، تو آپ عام طور پر ایک مکمل انڈہ ٹرے صنعت بنانے کے لیے کتنا محنت کرتے ہیں؟ تجربات سے پتہ چلا کہ صرف 4 کارکنان کی ضرورت ہوتی ہے: ایک انڈہ ٹرے پُولپنگ کے لیے، ایک مولڈنگ کے لیے، ایک ہاٹ پریس انڈہ ٹرے کی ثانوی پروسیسنگ کے لیے، اور ایک پیکنگ کے لیے۔

شولئی کی سروس

- پیشگی فروخت کی تفصیلی انڈے کی ٹرے کی پیداوار کے عمل کا تعارف، فیکٹری کا ویڈیو دورہ۔

- مشین کی جگہ کا ڈیزائن اور مفت آن لائن تنصیب کی ہدایات فراہم کرنا۔

- بعد از فروخت مسائل آن لائن حل کیے جاتے ہیں، اور پیداوار کے عمل میں تکنیکی مسائل میں مدد فراہم کی جا سکتی ہے

عمومی سوالات

انڈہ ٹرے مشین کی پیداوار کی صلاحیت کیا ہے؟

1,000–8,000 ٹکڑے/گھنٹہ، ماڈل اور خشک کرنے کے نظام پر منحصر ہے۔

یہ کون سے قسم کے انڈہ ٹرے تیار کر سکتا ہے؟

30 خانے والے انڈہ ٹرے، انڈہ کارٹن، پھلوں کے ٹرے، کپ کیریئرز، اور دیگر پلس مولڈڈ مصنوعات (سانچے بدل کر)۔

کیا سانچے کو کسٹمائز کیا جا سکتا ہے؟

ہاں۔ ایلومینیم یا پلاسٹک کے سانچے آپ کے ٹرے کے ڈیزائن کے مطابق کسٹمائز کیے جا سکتے ہیں۔

کیا آپ تنصیب اور بعد از فروخت سروس فراہم کرتے ہیں؟

ہاں۔ ہم لے آؤٹ ڈیزائن، آن لائن تنصیب رہنمائی، تربیت، اسپئر پارٹس کی فراہمی، اور انجینئر کی مدد فراہم کرتے ہیں اگر ضرورت ہو۔

اپنا انڈہ ٹرے کا کاروبار آج ہی شروع کریں!

ہمارے پیشہ ور انجینئرنگ ٹیم سے مفت پروجیکٹ کا جائزہ اور قیمت کا تخمینہ حاصل کریں — ہم آپ کی خام مال کی فراہمی، صلاحیت، اور بجٹ کے مطابق منافع بخش انڈہ ٹرے پیداوار پلانٹ ڈیزائن کرنے میں آپ کی مدد کریں گے۔