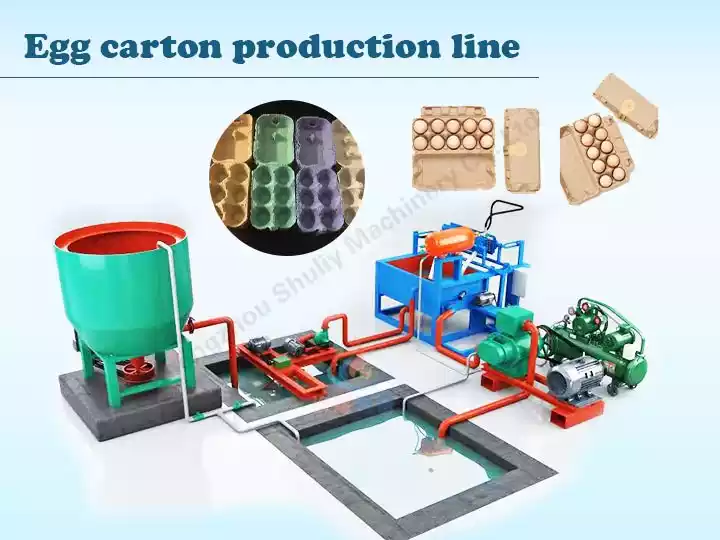

كيفية اختيار أفضل القوالب لآلة علب البيض الخاصة بك لإنتاج صواني عالية الجودة؟

الاستثمار في آلة علب بيض عالية الأداء هو الخطوة الأولى نحو عمل إعادة تدوير مربح. ومع ذلك، يتجاهل العديد من المشترين المكون الأكثر أهمية الذي يشكل المنتج النهائي فعليًا: القالب.

توفر الآلة القوة والشفط، لكن القالب يحدد ما إذا كنت تنتج صينية بيض قياسية تحتوي على 30 حفرة أو علبة بيض سوبر ماركت فاخرة تحتوي على 12 حبة. يمكن أن يحد استخدام مادة أو تصميم قالب غير مناسب من إمكانيات أفضل آلة علب البيض، مما يؤدي إلى أسطح خشنة أو كسر متكرر.

المواد مهمة

عند طلب آلة علب البيض، عادةً ما يسأل المصنع عن نوع مادة القالب التي تفضلها. يؤثر اختيارك على عمر القالب وجودة الصينية.

قوالب بلاستيكية

مصنوعة من بلاستيك هندسي ABS، وهي الخيار القياسي للآلات المبتدئة.

- المزايا: تكلفة منخفضة وخفيفة الوزن.

- العيوب: لديها عمر أقصر (1-2 سنة) ويمكن أن تتشوه قليلاً تحت الحرارة والضغط الشديدين لعملية التجفيف.

الحكم: جيد لآلات علب البيض الصغيرة أو صواني النقل البسيطة حيث لا تكون الجمالية هي الأولوية القصوى.

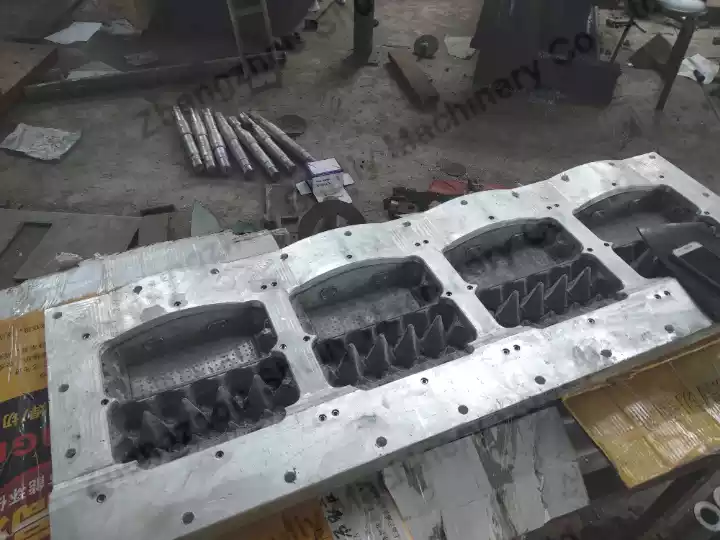

قوالب ألمنيوم

بالنسبة لمعظم المصانع التجارية، الألمنيوم هو الملك.

المزايا: هذه القوالب مصقولة بدقة باستخدام تقنية CNC. فهي متينة، مقاومة للتآكل، وتوفر نقل حرارة ممتاز.

لماذا تختارها: إذا كنت تريد لآلة علب البيض الخاصة بك إنتاج صواني بسطوح ناعمة وحواف حادة لسنوات، فإن الألمنيوم هو الاستثمار الأفضل. عادةً ما يدوم من 5 إلى 10 سنوات.

قوالب نحاسية

يستخدم النحاس غالبًا لتشكيل سطح شبكة في الإنتاج عالي الجودة.

- المزايا: متانة فائقة وشبكة أدق، مما يخلق سطحًا أكثر نعومة من اللب الورقي.

- الحكم: مثالية لخطوط الإنتاج الصناعية الثقيلة التي تنتج تغليفات تجزئة عالية الجودة.

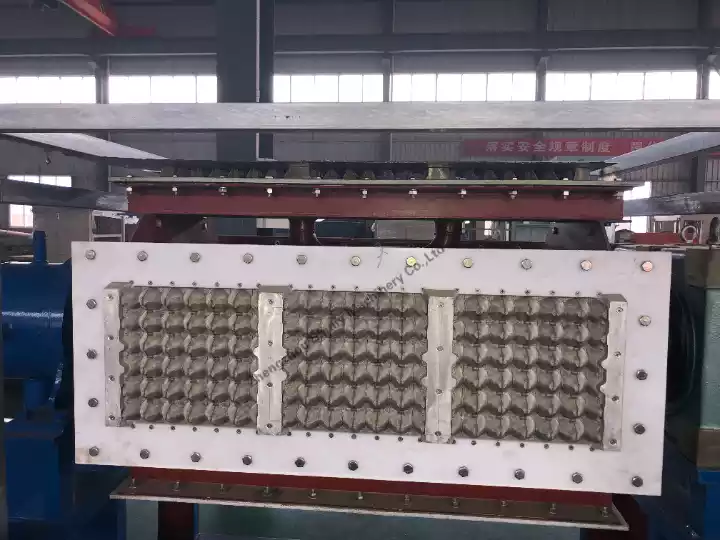

تكييف آلة علب البيض لمنتجات مختلفة

واحدة من أكبر مزايا آلة علب البيض الحديثة هي مرونتها. لا تحتاج إلى آلة منفصلة لكل منتج؛ فقط تحتاج إلى تغيير القوالب.

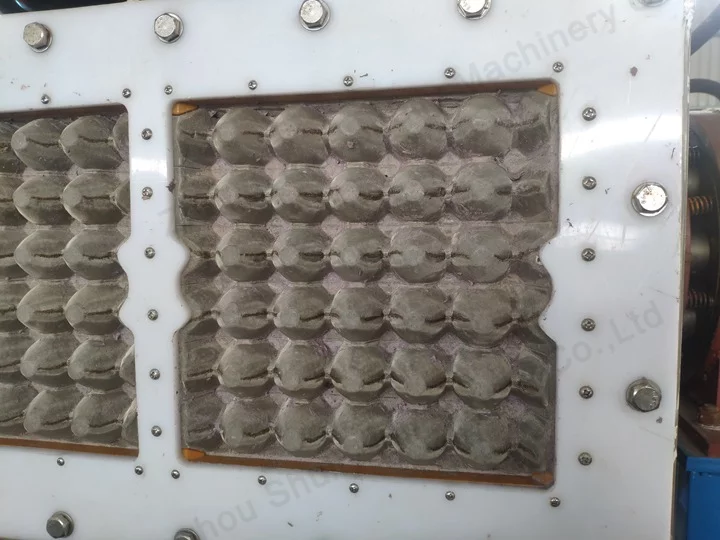

صواني بيض الدجاج القياسية

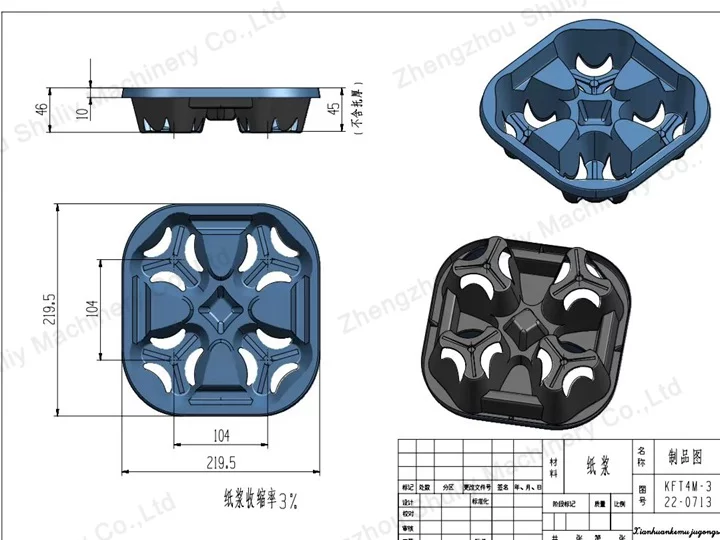

التطبيق الأكثر شيوعًا هو الصينية المفتوحة ذات 30 حفرة.

- مواصفات القالب: مصمم لبيض يتراوح وزنه بين 50 جم و65 جم.

- التخطيط: عادةً ترتيب 5×6. هذا هو المعيار العالمي لنقل من المزرعة إلى السوق.

علب البيض للبيع بالتجزئة

إذا كنت تريد البيع للسوبر ماركت، فإن آلة علب البيض الخاصة بك تحتاج إلى قوالب معقدة.

- تصاميم: صناديق 6، 10، أو 12 حبة مع أغطية مدمجة وأقفال قفل.

- المتطلبات: تتطلب هذه القوالب دقة أعلى (عادة الألمنيوم) لضمان إغلاق الغطاء بشكل مثالي وقوة المفصل.

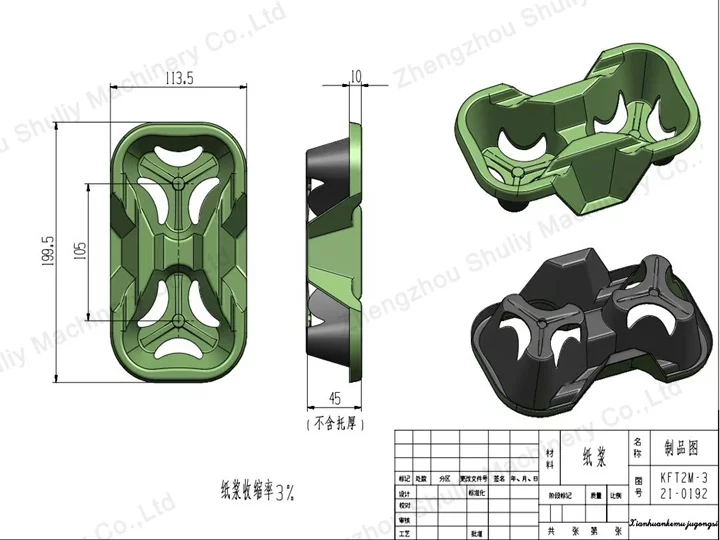

بيض البط، الإوز، والسمان

لا تدخل بيضة بط في صينية دجاج!

- بيض السمان: يمكن تعديل حجم صينية قياسية لتحتوي على 70-90 بيضة سمان صغيرة.

- بيض البط أو الإوز: تتطلب هذه تجاويف أعمق وأعرض لمنع السحق.

- المرونة: من خلال الاحتفاظ بمخزون من قوالب مختلفة، يمكن لآلة علب البيض الخاصة بك التبديل من إنتاج بيض الدجاج إلى بيض السمان في أقل من ساعة، مما يسمح لك بخدمة عملاء متنوعين.

لماذا تعتبر قوالب CNC الدقيقة ضرورية؟

في الماضي، كانت القوالب تُصب بشكل تقريبي. اليوم، نستخدم تشغيل الآلات بالحاسوب للتحكم العددي لصنع قوالب الألمنيوم الخاصة بنا.

لماذا يهم هذا لآلة علب البيض الخاصة بك؟

التوازن: قوالب CNC متوازنة تمامًا، مما يقلل من الاهتزاز والتآكل على الآلة.

إزالة القالب: التجاويف الدقيقة تضمن سهولة إخراج الصينية المبللة من القالب، مما يسرع دورة الإنتاج.

الجمالية: خطوط حادة ونظيفة تجعل صوانيك الورق الخاصة بك تبدو احترافية، مما يساعد على تميز علامتك التجارية.

استنتاج

آلة علب البيض الخاصة بك هي قوة متعددة الاستخدامات، لكن إنتاجها يعتمد فقط على جودة القوالب التي تثبتها. سواء كنت بحاجة إلى قوالب بلاستيكية رخيصة لنقل بالجملة أو قوالب ألمنيوم دقيقة لعلب السوبر ماركت، فإن الاختيار الصحيح ضروري لتحقيق العائد على الاستثمار.

هل أنت مستعد لتخصيص خط الإنتاج الخاص بك؟ نحن نقدم مجموعة كاملة من القوالب المتينة المعالجة بواسطة CNC والمتوافقة مع آلة علب البيض عالية الكفاءة لدينا.