تم تقديم آلة حاوية البيض بنجاح للعميل في زامبيا

مؤخراً، قمنا بتصدير مجموعة من خط إنتاج صواني البيض الأوتوماتيكية بالكامل إلى عميل من قطاع الأعمال الزراعية في زامبيا. لقد كان العميل مشغولاً منذ فترة طويلة في تربية الدجاج وإدارة أعمال توزيع الجملة المحلية.

من أجل حل مشكلة التلف أثناء نقل البيض وتعزيز صورة العلامة التجارية، قاموا بشراء آلة صناديق البيض الخاصة بنا لتغليف صناديق البيض المصنوعة ذاتيًا من اللب. بعد أن تم تشغيل المعدات، لم يقلل ذلك فقط من تكلفة التعبئة الاصطناعية بشكل كبير، بل ساعد أيضًا العميل في إنشاء نظام تغليف منتج كامل، مما يعزز بشكل فعال تنافسية السوق.

خلفية العملاء

كبلد زراعي مهم في جنوب إفريقيا، كانت زامبيا تتطور بسرعة في تربية الدواجن في السنوات الأخيرة، وتعتبر البيض، كواحد من المنتجات الزراعية الرئيسية، في طلب قوي في السوق المحلية.

العميل يدير مزرعة بيض متوسطة الحجم تنتج عشرات الآلاف من البيض يوميًا، وقد اعتمد لفترة طويلة على التعبئة البسيطة المستوردة أو الاصطناعية لبيع البيض.

نظرًا لعدم استقرار إمدادات صناديق الورق المحلية وارتفاع تكلفتها، يخطط العميل لبناء خط تعبئة قوالب اللب الخاص به وإنتاج صناديق البيض الخاصة به لتقليل التكاليف وتحسين سلامة نقل البيض ووحدة العلامة التجارية.

حلول مخصصة من شولي

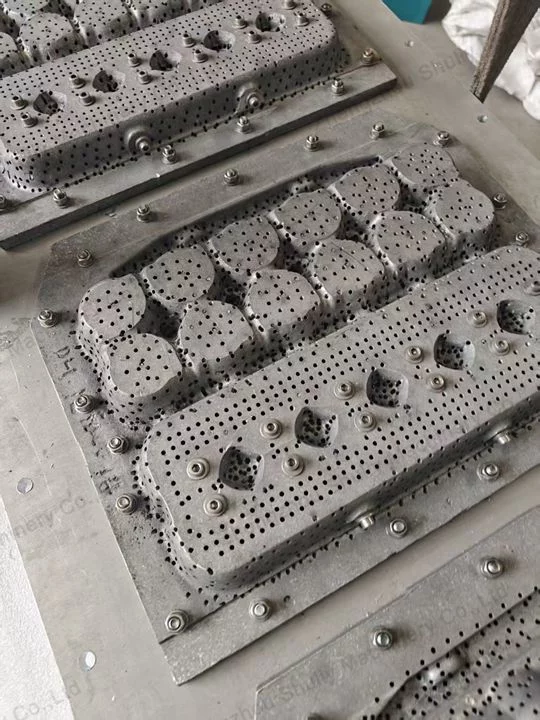

استنادًا إلى موقع العميل، وتكوين الطاقة، والإنتاج اليومي، ومتطلبات معيار التعبئة، نوصي بخط إنتاج أطباق البيض آلي، بما في ذلك: ماكينة تصنيع اللب، خزان التخزين المخصص، ماكينة تشكيل أطباق البيض، مكبس أطباق البيض الساخن، ومجفف حزام الشبك.

الخط سهل التشغيل وله قدرة إنتاجية مستقرة تبلغ حوالي 3000-3500 صينية بيض في الساعة.

نظرًا للمناخ الجاف والقيود الطاقية في منطقة العميل، اقترحنا استخدام الرياح الطبيعية والتدفئة الكهربائية للمساعدة في نظام التجفيف، وهو ما يعد صديقًا للبيئة وفعالًا من حيث الطاقة.

نحن نقدم أيضًا للعملاء معلومات تقنية، مثل حساب جرعة الورق وطرق استبدال القوالب، لضمان أن يتمكن العملاء من البدء بسرعة.

مزايا شولي

بعد الانتهاء من إنتاج المعدات، سنقوم بترتيب مهندسين لاختبار الآلة بالكامل، وتصويرها، وتوليد بيانات فيديو كاملة للعملاء لتأكيد تأثير الإنتاج، مع توفير صور تغليف متعددة الزوايا.

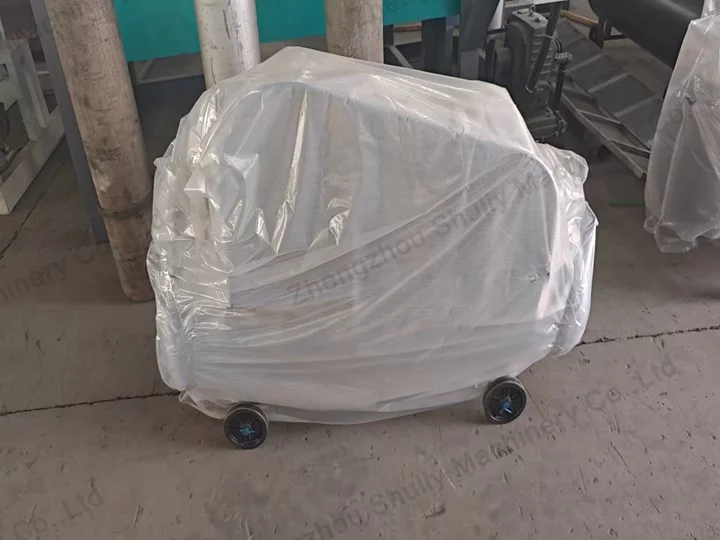

وتعتمد عبواتنا تصميم حماية متعدد الطبقات. يتم تغليف كل آلة وأجزائها بفيلم مقاوم للماء، وتعزيز داخلي من الرغوة، ومعالجة مضادة للاهتزاز ومضادة للصدأ. يتم تثبيت الآلة بالكامل في صندوق خشبي قياسي للتصدير لضمان الاستقرار والسلامة أثناء النقل لمسافات طويلة.

يمكن للعملاء أيضًا التحقق من البضائع في الوقت الفعلي من خلال مكالمة فيديو، وعرض عن بُعد لحالة اختبار المعدات، مما يحقق حقًا "مصنع عبر الإنترنت، وراحة البال في الشراء".

تعليقات حقيقية من العملاء

بعد وصول خط إنتاج صواني البيض إلى زامبيا، قدم فنينا فيديو إرشادات التركيب عن بُعد في المرة الأولى، وساعدوا العميل في إكمال تركيب النظام وضبطه من خلال رابط الفيديو.

تعليق العميل هو أن جميع الآلات تعمل بشكل مستقر، وصناديق البيض المصبوبة ذات حجم موحد وصلابة معتدلة، وسرعة التجفيف سريعة ومعدل تأهيل المنتج مرتفع.

بعد بدء الإنتاج، يمكن لآلة صناديق البيض تلبية احتياجات العملاء من التعبئة الذاتية كل يوم، ويمكن بيع صناديق البيض الفائضة للعالم الخارجي، مما يحول الورق المهدر إلى ربح، وفتح قنوات جديدة لتوليد الدخل.

العميل راضٍ جدًا، ويخطط للتفاوض معنا بشأن طلبات قوالب إضافية وخطة توسيع المرحلة الثانية من خط الإنتاج.

إذا كان لديك أيضًا حاجة لماكينة تصنيع أطباق البيض، فلماذا لا تتحدث إلى مصنع محترف مع ضمان خدمة ما بعد البيع مثلنا؟ نحن دائمًا نرحب باستفساراتك.