自动纸蛋托生产线

| 型号 | SL-4*4 |

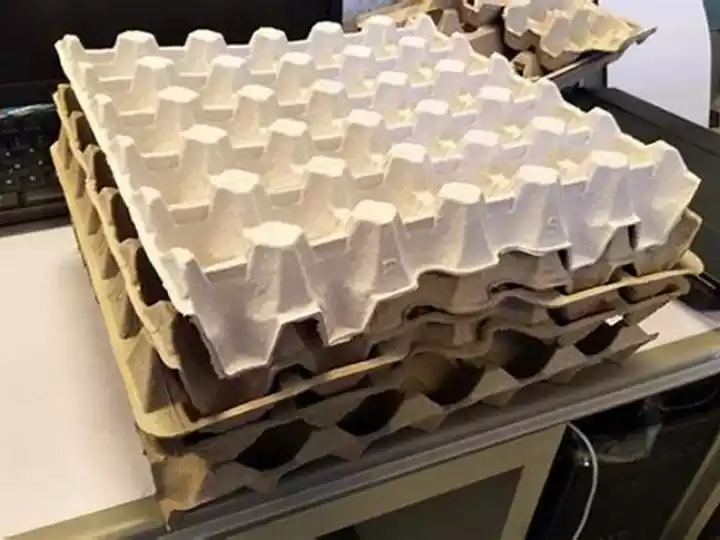

| 产品 | 蛋托 |

| 容量 | 3000-3500个/小时 |

| 纸张消费 | 280千克/小时 |

| 水消耗 | 560千克/小时 |

| 使用的能源 | 78千瓦时 |

| 工人编号 | 4-5 |

您现在可以向我们的项目经理询问技术细节

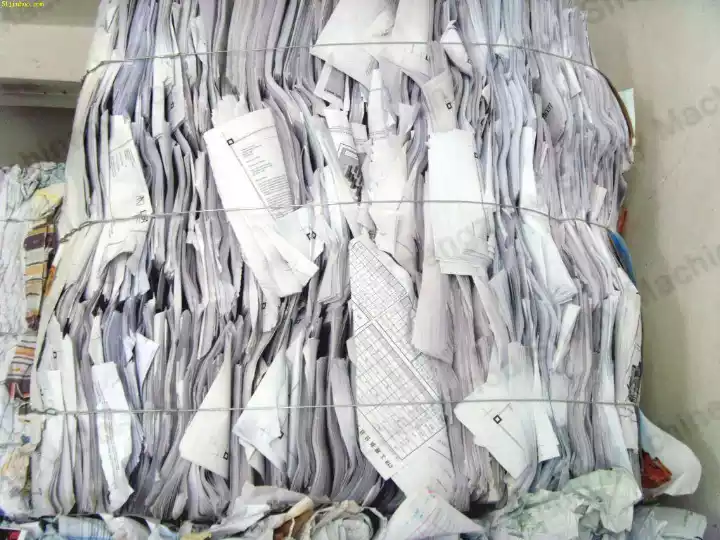

自动纸质蛋托生产线是一种用于生产蛋托的设备。蛋托机利用废纸制造蛋托,是一种非常环保的产品。

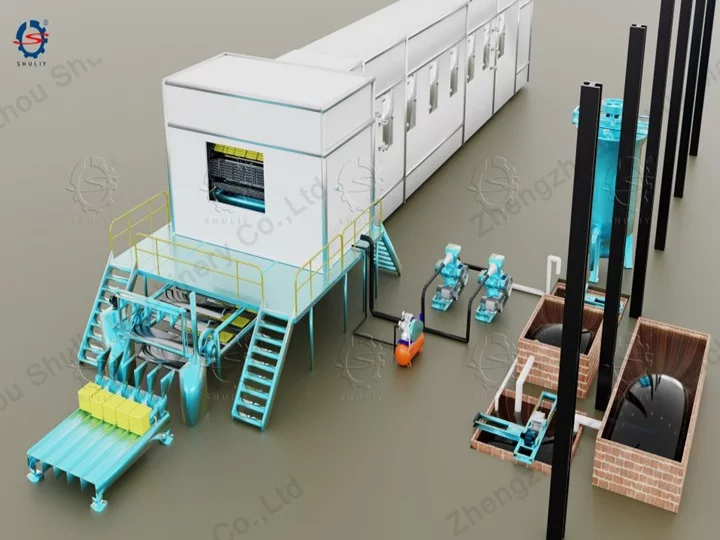

纸蛋托生产线主要包括制浆部分、蛋托成型部分、干燥部分和包装部分。舒利的纸蛋托生产线产量为1000-8000件/小时。

纸蛋托生产线是如何工作的?

自动纸蛋托生产线工艺

蛋托浆料

纸蛋托生产线的生产需要建三个池,分别用于制浆、浆料储存和水池储存。所需设备为液压制浆机,搅拌时间约为40分钟。

具体生产工艺是将废纸通过制浆机粉碎,加入水,然后送入浆料储存罐,再将浆料放入浆料混合罐调节浓度,即可使用。均质机将浆料搅拌均匀。

具有良好稠度的浆料可以输入浆料供应罐进行处理。制浆机的结构包括几个部分:制浆机、均质机、浆料泵、振动筛和浆料分解机。

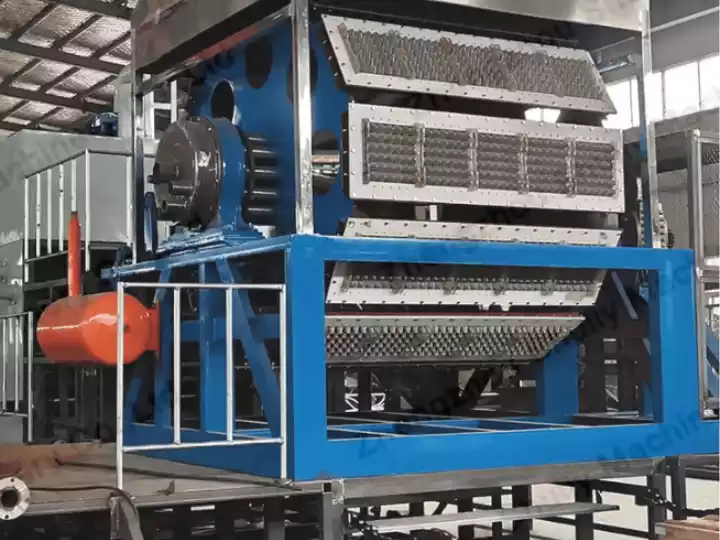

蛋托成型

成型简单分为两个步骤。第一步,将浆料供应罐中的浆料通过真空吸附系统吸附到模具上。吸附完成后,将模具转移到模具上成型蛋托的形状。

第二步,将吸附在模具上的蛋托通过空气压缩机转移到传输系统,机器可以自动取出。

蛋托成型机的结构包括蛋托成型机、模具、真空泵、负压罐、水泵、空气压缩机和模具清洗机。

蛋托干燥

蛋托的干燥方法分为自然干燥、砖窑干燥和干燥机干燥。干燥方法根据产量和当地气候而定。使用纸蛋托干燥机,蛋托可以在短时间内干燥。

热压成型

刚完成的蛋托在充水后,经过干燥,水分减少,蛋托表面会留下一些皱纹,影响使用。但如果想让表面更光滑,则需要用热压成型机进行热压。成型后的蛋托会更美观。

蛋托包装

包装是纸浆蛋托生产线的最后一步。蛋托包装机可以将多个蛋托紧密堆叠在一起。

蛋托机参数

| 型号 | 产能 | 纸张消费 | 水消耗 | 使用的能源 | 工人 |

| SL-3*1 | 1000-1500个/小时 | 120千克/小时 | 300千克/小时 | 32千瓦/小时 | 3-4 |

| SL-4*1 | 1500-2000个/小时 | 160千克/小时 | 380千克/小时 | 45千瓦/小时 | 3-4 |

| SL-3*4 | 2000-2500个/小时 | 200公斤/小时 | 450千克/小时 | 58千瓦时 | 4-5 |

| SL-4*4 | 3000-3500个/小时 | 280千克/小时 | 560千克/小时 | 78千瓦时 | 4-5 |

| SL-4*8 | 4000件/小时 | 320千克/小时 | 600千克/小时 | 80千瓦/小时 | 5-6 |

| SL-5*8 | 5000件/小时 | 400千克/小时 | 750千克/小时 | 85千瓦/小时 | 3-4 |

| SL-6*8 | 6000件/小时 | 480千克/小时 | 900千克/小时 | 90千瓦/小时 | 3-4 |

| SL-8*8 | 8000个/小时 | 640千克/小时 | 1040千克/小时 | 100千瓦/小时 | 3-4 |

无论您是寻找小容量的蛋托生产设备还是大容量的蛋托机,我们都能满足您的需求。我们提供产量为1000件/小时至8000件/小时的机器供您选择。

纸蛋托生产线的优势

- 无污染,蛋托生产过程没有环境污染,但属于资源回收利用行业

- 成本低,因为原材料是用纸,成本较低

- 全自动化生产,节省劳动力。整个蛋托生产过程只需要 3-4 人

哪些原材料可以用于生产纸质蛋托生产线?

蛋托的生产可以利用废旧纸箱、废旧书籍、A4纸打印或废旧蛋托进行回收。因此,蛋托生产的原材料非常广泛。

纸蛋托生产线的3D视频

为什么蛋托机受到欢迎?

统计数据显示,蛋托机的销量不断增加。在与客户对接的过程中,我们发现他们制造蛋托机的主要原因有三点。

首先,蛋托机属于资源回收行业,非常环保,也得到了地方政府的支持。

其次,纸蛋托生产线的原材料易于获取。蛋托机所用的原材料主要是废纸,在许多国家都能轻松收集到。

最后,当然,销售蛋托非常容易。鸡蛋对蛋托的需求很大,这些都是消耗品,所以客户很容易接受。许多人愿意选择生产蛋托以获利。

蛋托的制浆过程是什么?

浆料主要需要控制水与浆料的比例。一般来说,水与浆料的比例为1:3,并且要均匀混合。在工艺中需要加入一定量的胶水或石灰水,这可以使蛋托更牢固。这些工作通常以蛋托的形式完成。

- 蛋托采用废纸生产,其质量当然与原材料密切相关。

- 这也与机器有关,优质机器生产的蛋托更坚固

- 另一方面,这也与生产技术有关。蛋托的生产也有许多技能要点,例如制浆的比例和添加剂的数量,这些都需要在不进行实验的情况下进行计算。

纸蛋托生产线的用工安排

大致了解蛋托的生产工艺后,通常需要多少劳动力来建立完整的蛋托产业?经过实验发现,只需4名工人:一名负责蛋托制浆,一名负责蛋托成型,一名负责热压蛋托的二次加工,一名负责包装。

舒利的服务

- 售前详细的蛋托生产过程介绍,工厂视频导览

- 设计机器放置并提供免费的在线安装说明

- 售后问题在线解决,生产过程中的技术问题可以得到帮助解答

常见问题解答

蛋托机的产能是多少?

根据型号和干燥系统的不同,产量为每小时1,000–8,000个。

它可以生产哪些类型的蛋托?

30孔蛋托、蛋盒、水果托、杯托及其他浆模制品(通过更换模具)。

模具可以定制吗?

是的。铝制或塑料模具可以根据您的托盘设计定制。

你们提供安装和售后服务吗?

是的。我们提供布局设计、在线安装指导、培训、备件供应和工程师支持(如有需要)。

今天就开始你的蛋托业务吧!

联系我们专业的工程团队,免费进行项目评估和报价——我们将帮助您设计一个盈利的蛋托生产厂,量身定制,满足您的原料供应、产能和预算。