7 необходимых шагов для открытия фабрики по производству яичных лотков

С растущим спросом на яйца экологически чистые биодеградируемые коробки для яиц постепенно заменяют пластиковую упаковку и становятся основным выбором для глобальной перевозки яиц.

Картонные машины используют макулатуру в качестве сырья, что обеспечивает низкие вложения, высокую прибыль и значительные экологические преимущества, делая их популярным проектом среди начинающих инвесторов.

Итак, как же создать фабрику подложек с нуля?

Шаг 1: оценка местных ресурсов макулатуры

Основное сырьё для подложек включает отходы картона, выброшенные книги, газеты, бумажные обрезки и т. д.

Перед созданием фабрики изучите местные каналы сбора макулатуры, например:

- Поставки макулатуры от бумагоделательных комбинатов

- Центры переработки

- Обрезки бумаги от типографий

- Местные центры сортировки отходов

Стабильность поставок сырья и возможность расстояний транспортировки являются критическими факторами долгосрочной рентабельности проекта.

Шаг 2: выбор подходящего места под фабрику

Выбор места фабрики должен соответствовать следующим критериям:

- Близость к сырью и источникам воды (процесс переработки бумаги требует значительных объёмов воды)

- Удобный доступ к транспорту (облегчает отгрузку готовой продукции)

- Расстояние от жилых районов (благоприятно для экологических разрешений и контроля шума)

Просторные помещения: общая площадь не менее 1 500 квадратных метров, включая зоны для пульпирования, формования, сушки, хранения и офисы.

Шаг 3: определить конфигурацию оборудования и тип производственной линии

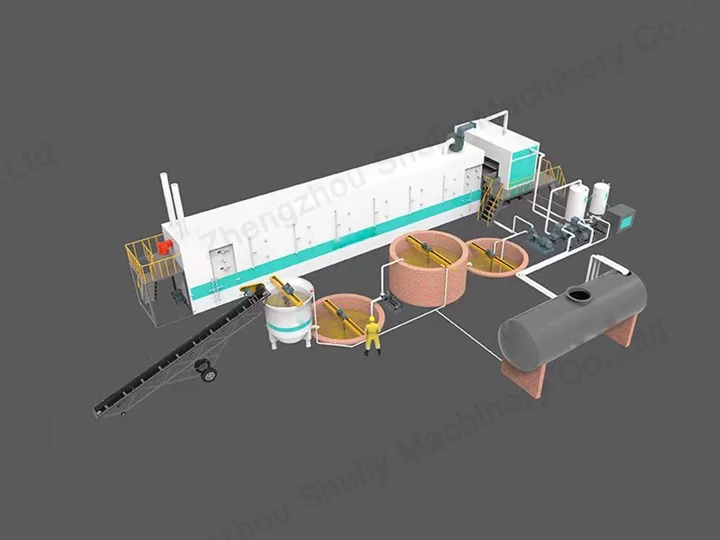

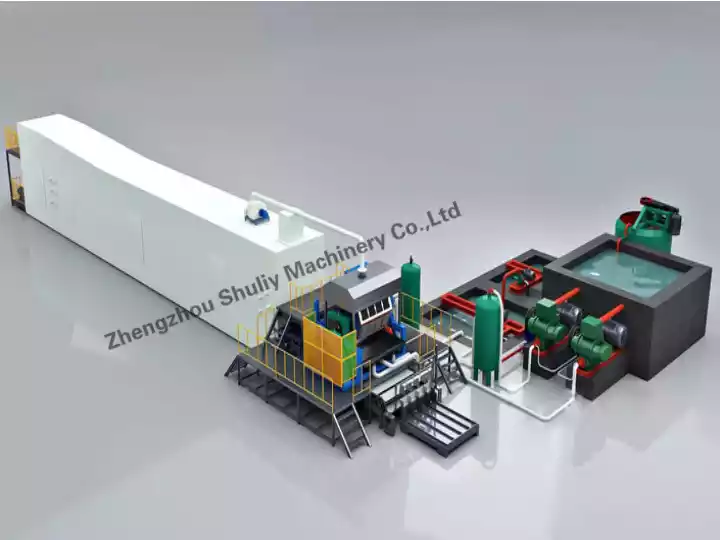

В зависимости от инвестиционного бюджета и масштаба производства общие линии по производству подложек делятся на следующие:

| Тип | Соответствующий масштаб | Особенности |

|---|---|---|

| Полуавтоматическая производственная линия | Мелкие фабрики | Низкие инвестиции на начальную пробную продукцию |

| Полностью автоматизированная производственная линия | Средние и крупные фабрики | Высокая автоматизация, стабильный выпуск |

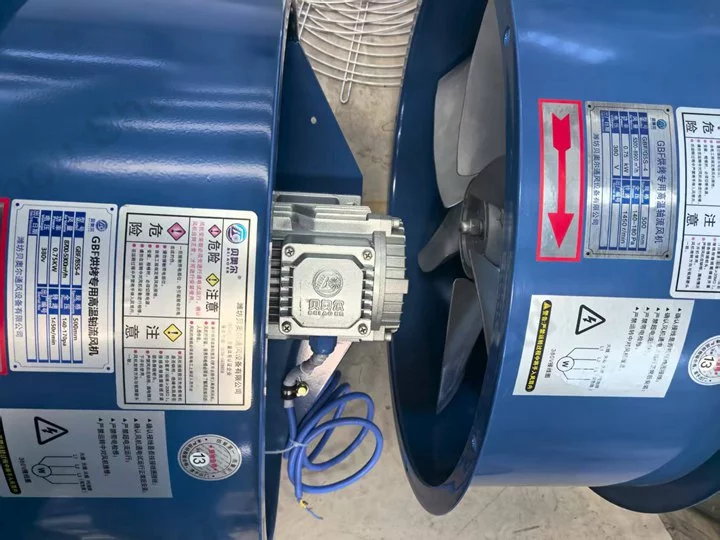

Линии производства в основном включают: мелкозернистый измельчитель, машина для формовки подложек, сушилка для подложек, горячий пресс подложек, и упаковочная машина

Шаг 4: планирование процесса производства подложек для яиц

Весь процесс производства подложек для яиц следующий:

Пульпирование макулатуры → Формование → Сушка → Горячий пресс и формование → Упаковка и складирование

Автоматизированная линия требует всего 1–2 оператора. Она энергоэффективна и экологична на протяжении всего процесса, оснащена автоматическим контролем температуры и автоматическим подачей целлюлозы, значительно снижая трудозатраты.

Шаг 5: обеспечить экологические и санитарные разрешения

Перед созданием фабрики ознакомьтесь с местными экологическими правилами:

- Создать систему повторного использования сточных вод для предотвращения загрязнения

- Выбор энергоэффективных систем сушки на топливе

- Провести тесты на шум и выбросы газов

- Получить законные разрешения на производство и экологическую

Соблюдение требований не только снижает риски, но и улучшает образ компании.

Шаг 6: установить стабильные каналы продаж

Клиенты, обычно покупающие подложки:

- Птицеводческие хозяйства и заводы по упаковке яиц

- Оптовые рынки яиц и продуктовые компании

- Супермаркеты и цепочки сельскохозяйственной продукции

- Экспортные рынки (Средний Восток, Африка, Юго-Восточная Азия)

Шаг 7: рассчитать срок окупаемости

На примере линии по производству подложек Шулий 4000 шт/ч:

Начальные вложения в оборудование: примерно $60,000–$80,000

Ежедневная выработка подложек: примерно 30,000–40,000 единиц

По рыночным ценам $0.04–$0.06 за подложку, дневная выручка составляет примерно $1,200–$2,400

С чистой прибылью 35%–45%, срок окупаемости составляет 6–10 месяцев

Краткое содержание

Создание фабрики по производству подложек для яиц не только позиционирует вас как участника экологической защиты, но и как получателя выгоды устойчивой экономики.

Выбирая автоматическую линию по производству подложек, вы получаете:

- Контроль затрат

- Упрощённая эксплуатация

- Быстрая окупаемость

- Обширные рыночные перспективы

Сейчас самое подходящее время для входа в индустрию формованной целлюлозы. Свяжитесь с нашей командой экспертов сегодня для индивидуального решения по производству подложек подберите под ваши потребности!