Как выбрать правильную конфигурацию линии производства для вашего бизнеса по изготовлению поддонов для яиц?

Многие задаются общим вопросом: при подготовке к созданию линии по производству поддонов для яиц, следует ли выбрать полуавтоматическую или полностью автоматическую линию?

Это вопрос без единственно правильного ответа. Оптимальный выбор полностью зависит от ваших уникальных бизнес-условий, включая стартовый капитал, место расположения фабрики, локальные затраты на рабочую силу и ваши маркетинговые цели.

Option 1: полуавтоматическая линия производства

Полуавтоматическая линия обычно включает автоматические помольную и формовочные системы, но требует большего ручного участия на этапах сушки и упаковки.

Типичная конфигурация: помольная система + формирователь поддона для яиц + естественная сушка или кирпичная печь + ручная сортировка и упаковка.

Подходит для:

- Стартапы и мелкие инвесторы: ограниченный бюджет, стремящийся запустить проекты с минимальными начальными инвестициями.

- Мелкие птицеводы: производство в основном лотков для яиц для собственного использования с умеренными требованиями к выпуску.

- Локации с благоприятными условиями: обильная, доступная земля и рабочая сила в сочетании с жарким, сухим климатом, подходящим для естественной сушки воздушным способом.

Ключевые преимущества полуавтоматизированных линий:

- Значительно сниженные первоначальные инвестиции: это самое убедительное преимущество. Устраняя дорогостоящие автоматы линии сушки металла и системы упаковки, общая стоимость производственной линии существенно снижается.

- Высокая гибкость: вы можете выбрать естественную сушку по погодным условиям или гибко организовать ручную сушку и сортировку в зависимости от объема заказа. Эта адаптивность бесценна на этапе неопределенности бизнеса.

- Гибкие требования к площадке: если выбирать естественную сушку, вам нужна только открытая площадка без строгих требований к высоте или конструкции фабрики.

Факторы для рассмотрения:

- Погодные условия и зависимость от труда: естественная сушка крайне чувствительна к погодным условиям, дожди могут остановить производство. Кроме того, требуется нанимать больше рабочих для транспортировки, сушки и сбора яиц.

- Относительно низкая производственная эффективность: этап сушки является узким местом во всей технологической цепочке, ограничивая дневной выпуск.

Вариант 2: полностью автоматизированная линия производства

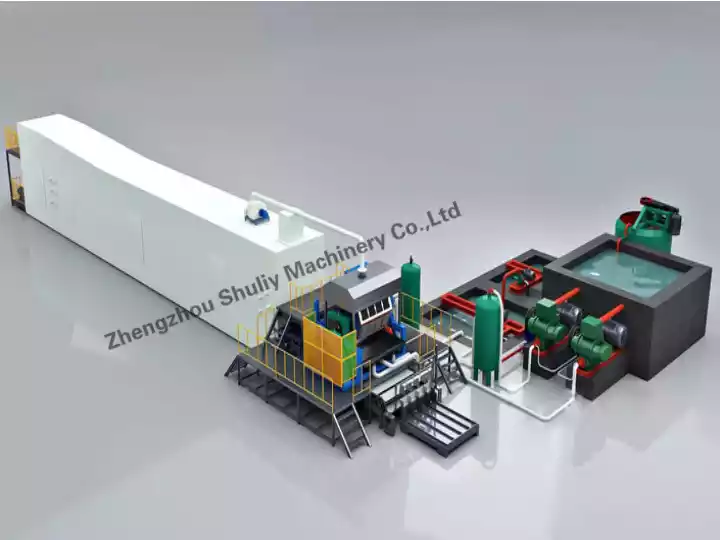

Полностью автоматизированная линия достигает сквозной автоматизации от подачи макулатуры до готовой упаковки поддонов, минимизируя ручное вмешательство.

Типичная конфигурация: помольная система + формирователь поддонов для яиц + автоматизированная линия сушки металла + автоматическая укладка, счет, горячее прессование и упаковочная система

Подходит для:

- Профессиональные производители egg tray: целевое обеспечение оптовой поставки крупным хозяйствам, дистрибьюторам яиц или супермаркетам.

- Операторы с ограниченным пространством или рабочей силой: ограниченная площадь фабрики или высокая стоимость рабочей силы в регионе.

- Предприятия, стремящиеся к качеству и эффективности: стремление к созданию стандартизированных, масштабируемых современных фабрик.

Ключевые преимущества полностью автоматизированной линии:

- Массовый выпуск и эффективность: автоматическая линия сушки металла работает 24/7 без перерывов, не зависит от погодных условий.

- Минимальная зависимость от рабочей силы: требуется всего 3-5 сотрудников для мониторинга и эксплуатации, что существенно снижает затраты на труд и управление.

- Постоянное высокое качество: точный контроль температуры и времени сушки обеспечивает однородную сушку и прочность каждой партии лотков для яиц. Дополнительные формовочные машины с горячим прессованием могут дополнительно улучшить внешний вид лотков за счет более ровной, эстетически приятной поверхности, повышая ценность продукции.

- Компактный след на площадке: многоуровневая конструкция линии сушки металла максимизирует выпуск на квадратный фут, значительно экономя ценное пространство на фабрике.

Факторы для рассмотрения:

- Более высокая первоначальная инвестиция: начальные капитальные затраты на полностью автоматизированные линии выше, чем на полуа automation-решения.

- Большие требования к энергии: автоматизированные линии сушки требуют стабильного и достаточного источника тепла (газ природный, дизельное топливо, пропан-бутан и т. д.).

Линия по производству поддонов для яиц на заказ Taizy

Независимо от того, выберете ли вы полуавтоматическую или полностью автоматическую систему, мы предлагаем индустриальные лидеры по-надежности. Наши линии по производству поддонов для яиц разработаны с учетом эффективности, долговечности и гибкости.

Высокая эффективность, энергосберегающая pulping система

Наши гидравлические помолы эффективно разбивают макулатуру на тонкую, однородную массу с меньшим расходом воды и электроэнергии.

Многоэтапные системы сит и де-облей поднимают сохранение длинного волокна, улучшая использование целлюлозы из источника.

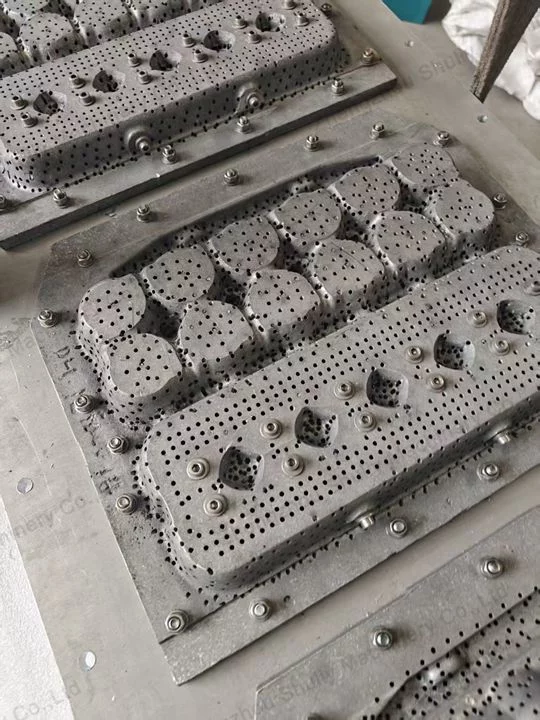

Гибкие индивидуальные формы

Наши формовочные станки обеспечивают стабильную, надежную работу и несравненную универсальность — их главная сила.

Через нашу услугу по индивидуальному изготовлению форм ваша машина выходит за рамки ограничений одного продукта:

- Упаковка яиц: мы адаптируем формы для лотков яиц и коробок от 6-до 30-гнездовых конфигураций.

- Сельскохозяйственная упаковка: легко производить фруктовые лотки, такие как коробки для яблок, лотки для авокадо и клубничные ящики.

- Упаковка для общественного питания: производство держателей для кофейных стаканов, подносов для еды на вынос и т. д.

- Промышленная упаковка: производит амортизирующие вкладыши для электроники, стеклянной тары, компонентов оборудования и т. д. Это означает, что единая инвестиция открывает доступ к нескольким рынкам. Просто поменяйте формы, чтобы без труда переключать линии производства, максимизируя вашу прибыль.

Гибкие варианты сушки

- Для полунавыгодных решений: мы предоставляем подробные чертежи по проектированию линии сушки в кирпичной печи и техническое руководство, чтобы помочь вам построить эффективную, долговечную сушильную камеру локально по минимальной стоимости.

- Для полностью автоматических решений: наша лидирующая в отрасли многоступенчатая линия сушки металла с инновационным дизайном циркуляции горячего воздуха обеспечивает более чем на 30% выше тепловую эффективность по сравнению с традиционными сушилками. Это приводит к меньшему расходу топлива и более быстрым скоростям сушки.

Интеллектуальные серверные системы поддержки

Для полностью автоматизированных линий мы предлагаем полные решения от станков горячей прессовки до упаковочного оборудования. Наши станки горячей прессовки создают поддоны с более гладкой поверхностью и большей прочностью, что значительно улучшает внешний вид и рыночную стоимость по сравнению со стандартными лотками.

Заключение

Выбор между полуавтоматической и полностью автоматизированной линией основан на балансе между «начальные инвестиции» и «долгосрочные преимущества».

Если ваш капитал ограничен, а у вас есть доступ к недорогой земле и рабочей силе, полуавтоматическая линия производства служит отличной отправной точкой в этой отрасли.

Если вы сосредоточены на долгосрочном росте и стремитесь построить эффективный, стабильный бренд с конкурентной масштабностью, тогда полностью автоматизированная линия производства безусловно является более разумной и перспективной инвестицией.

Независимо от вашего выбора, наша профессиональная команда всегда готова выслушать ваши потребности и предложить наиболее подходящее индивидуальное решение.

Свяжитесь с нами сегодня, чтобы наши консультанты проанализировали вашу конкретную ситуацию и порекомендовали конфигурацию линии производства, которая наилучшим образом соответствует вашим потребностям!