एक घानाई मुर्गी पालक किसान ने कैसे बेकार कागज को आय के एक नए स्रोत में बदल दिया

How can a business turn a daily waste product into its next big success? For one of our clients in Ghana, the answer was found in a single, powerful investment.

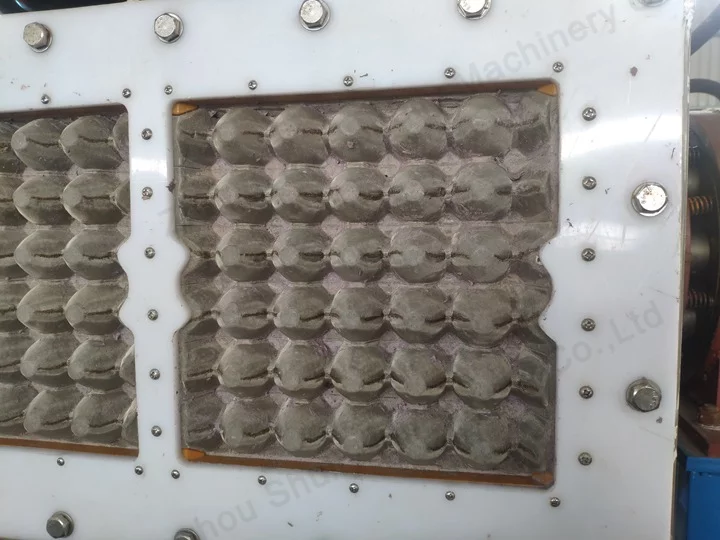

By purchasing our SL 4*1 egg tray machine and pulping system, this forward-thinking poultry farmer not only solved their packaging challenges but also dramatically reduced costs and created a thriving new business selling surplus egg trays to their local market.

Client background

Our client, the owner of a successful and growing poultry farm in Ghana. With a large daily egg output, the cost of purchasing egg trays was a significant and constant operational expense. The supply was often unreliable, leaving them with large amounts of waste paper and cardboard from feed bags and other packaging.

They saw an opportunity: what if they could use this abundant, low-cost resource to produce their high-quality egg trays? They needed a machine that was efficient, reliable, and perfectly suited to their production scale and local conditions.

Our solution

Our solution for the Ghanaian client was a complete, end-to-end system designed for immediate success. We provided:

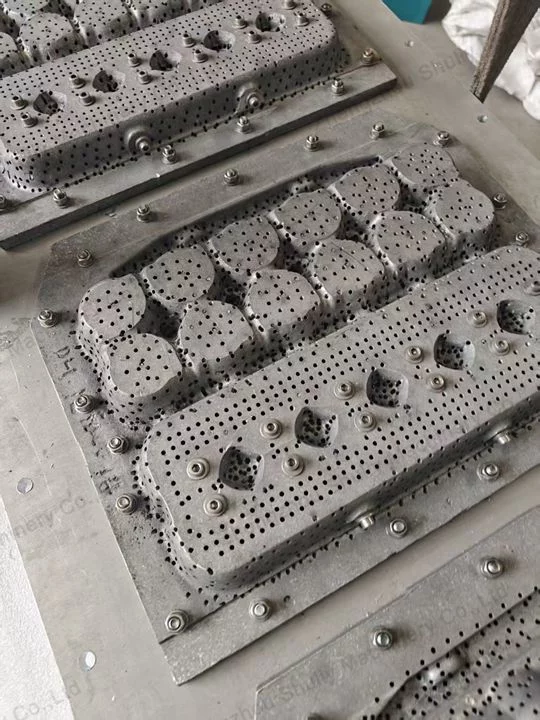

- A high-efficiency pulping system to easily break down their waste paper and cardboard into a fine, consistent pulp.

- The robust SL 4*1 egg tray forming machine, capable of producing approximately 2500 trays per hour.

- The full set of customized components, including the specialized transfer cart and the pre-configured electrical system, creates a solution perfectly tailored to their operational needs.

Advantages of the Shuliy egg tray machine

High efficiency and energy saving: stable production of tens of thousands of egg trays per day with low energy consumption.

Intelligent control: equipped with temperature and humidity control devices to ensure the quality of egg tray molding.

Flexible configuration: customizable voltage and plugs according to customer requirements. Different molds are also available to meet diverse market demands.

Customized production line: flexible customization of production lines according to customer needs.

Our promise: transparency and trust in every step

We understand that purchasing heavy machinery from overseas requires a high level of trust. That’s why we make our process completely transparent. Before the machine was shipped, we provided the client with:

- लाइव परीक्षण वीडियो: विस्तृत वीडियो जो उनके विशिष्ट मशीन को पूर्ण संचालन में दिखाते हैं, परफेक्ट अंडा ट्रे बनाते हुए।

- सावधानीपूर्वक पैकेजिंग तस्वीरें: हमारे पैकेजिंग प्रक्रिया की उच्च-रिज़ॉल्यूशन छवियां। हर घटक को पहले नमी से बचाने के लिए सुरक्षात्मक प्लास्टिक फिल्म में लपेटा गया था, फिर सुरक्षित रूप से मजबूत, निर्यात मानक लकड़ी के क्रेट में रखा गया और सहारा दिया गया ताकि ट्रांसिट के दौरान कोई नुकसान न हो।

- लाइव वीडियो निरीक्षण: हमने एक लाइव वीडियो कॉल का आयोजन किया, जिससे ग्राहक अपने मशीन और इसकी मजबूत पैकेजिंग का रियल-टाइम में व्यक्तिगत निरीक्षण कर सके, इससे पहले कि यह हमारे कारखाने से बाहर जाए।

Positive feedback from customers

The positive results came quickly after the machine arrived in Ghana. The client was extremely satisfied with the secure packaging and the pristine condition of the equipment. Our technical team provided detailed remote guidance via video call, assisting the client’s local team with a smooth and correct installation process.

Today, the factory is not only self-sufficient in egg trays but has also expanded its production. The efficiency of the egg tray machine has allowed them to become a key supplier to other farms in their region, significantly boosting their revenue and solidifying their position in the market.