¿Cómo construir una línea de producción completa de bandejas de vino?

A medida que se intensifica la prohibición global de plásticos, la industria del vino se está desplazando rápidamente hacia el embalaje de fibra moldeada. Las bandejas de vino de papel son ecológicas, protectoras y, cuando se hacen correctamente, lucen increíblemente premium.

Sin embargo, producir bandejas de vino de alta gama es diferente a hacer simples cajas de huevos. Requiere una línea de producción de bandejas de vino sofisticada que incluya pasos especializados como el prensado en caliente y el recorte de bordes para lograr un acabado suave y sin rebabas.

¿Planeas montar una fábrica? En esta guía, te guiamos a través del flujo de trabajo completo de una línea de máquinas de bandejas de vino de pulpa moldeada industrial, convirtiendo papel de desecho en ganancia.

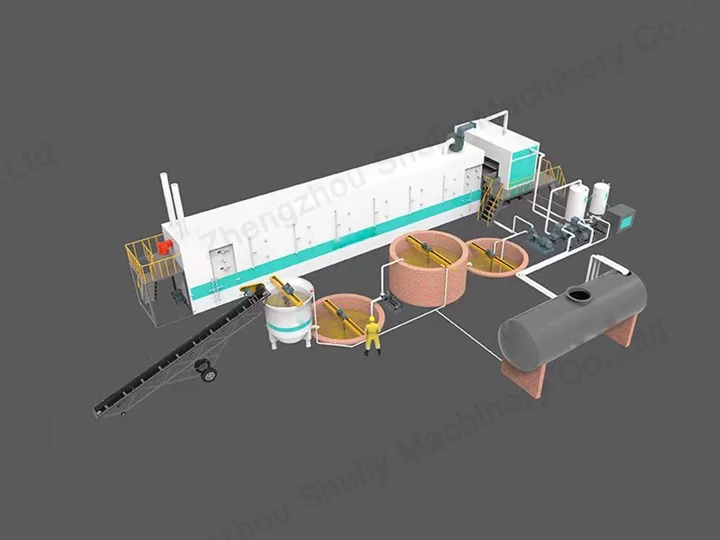

Sistema de pulpa

La calidad de la bandeja comienza con la pulpa. No puedes simplemente mezclar papel y agua al azar.

- Pulper hidráulico: el papel de desecho (periódicos, cartón, recortes) se arroja al pulper, donde se descompone en fibras.

- Refinamiento y control de consistencia: la pulpa se refina y ajusta a una concentración específica. Para las bandejas de vino, la consistencia de la fibra debe ser precisa para garantizar resistencia y absorción de golpes.

Sistema de formación

Este es el núcleo de la línea de producción de bandejas de vino.

- Absorción por vacío: los moldes de formación se sumergen en la pulpa. Una bomba de vacío potente aspira las fibras sobre el molde de malla, creando la forma húmeda de la bandeja de vino.

- Transferencia: la bandeja húmeda (que contiene aproximadamente 70% de agua) se transfiere al molde de transferencia.

- Tecnología clave: nuestras máquinas industriales de embalaje de fibra moldeada permiten moldes de cavidad profunda, ideales para sujetar de forma segura botellas de vino de 750 ml.

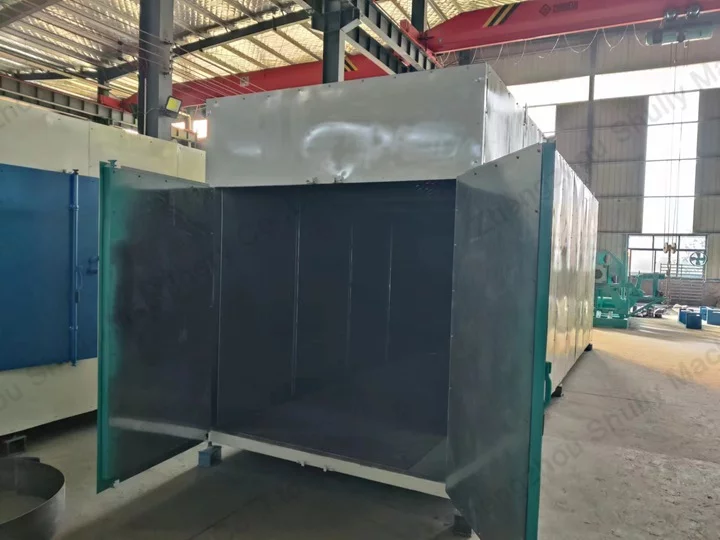

Sistema de secado

Las bandejas húmedas son demasiado frágiles para ser prensadas inmediatamente. Deben pasar por una Línea de Secado de Metal de Múltiples Capas.

- Proceso: las bandejas viajan a través de un túnel calentado por gas, diésel o electricidad.

- Resultado: el agua se evapora y la bandeja se endurece. Sin embargo, en esta etapa, la superficie todavía es áspera y “lanuda”, similar a una caja de huevos. Esto no es suficiente para un embalaje de vino premium.

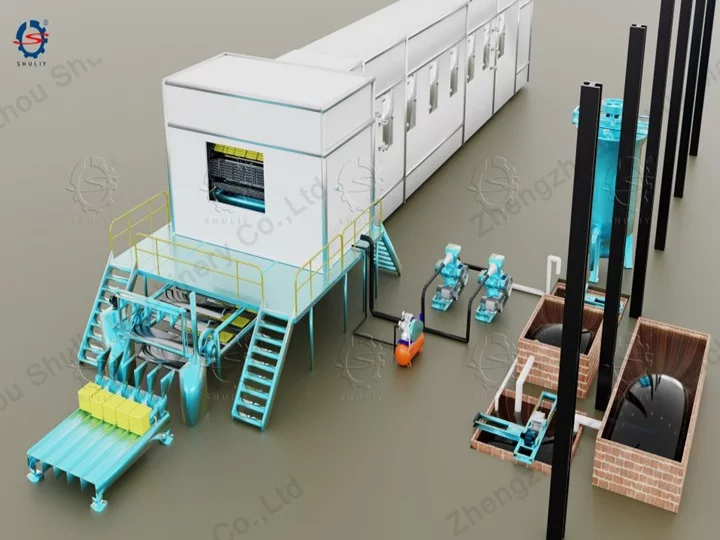

Sistema de Prensado en Caliente

Este es el secreto para bandejas de vino de alta calidad. Para hacer la superficie suave y las dimensiones precisas, las bandejas secas pasan a una máquina de prensado en caliente de pulpa de papel.

Alta temperatura y presión: la máquina utiliza moldes calentados (alrededor de 150°C-200°C) y presión hidráulica (10-20 toneladas) para comprimir la bandeja.

La transformación:

- Suavizado: las fibras ásperas se alisan, creando una superficie elegante y suave.

- Densificación: la bandeja se vuelve más delgada pero mucho más fuerte y rígida.

- Apilabilidad: las bandejas prensadas en caliente se apilan perfectamente, ahorrando espacio de envío.

Embalaje y Esterilización

El paso final en la línea de producción de bandejas de vino es el control de calidad y el embalaje.

- Esterilización UV: algunas líneas incluyen una estación de luz UV para garantizar que el embalaje sea apto para alimentos.

- Apilado: los apiladores automatizados cuentan y apilan las bandejas, listas para su envío a los viñedos.

¿Por qué elegir Shuliy para tu línea de producción de bandejas de vino?

Construir una fábrica implica más que solo comprar máquinas; requiere integración. En Shuliy, ofrecemos una solución llave en mano para el moldeo de pulpa.

- Control integrado: nuestras líneas cuentan con un sistema PLC centralizado que coordina el pulper, la máquina de formado y el secador para una operación sin problemas.

- Diseño de moldes personalizados: diseñamos moldes procesados con CNC para formas específicas de botellas (Burdeos, Borgoña, Champagne) para garantizar un ajuste perfecto.

- Eficiencia energética: nuestros últimos sistemas de prensado en caliente y secado reciclan calor, reduciendo tus costos de energía hasta en 30%.

- Tienda integral: desde la máquina de recorte de bordes hasta las bombas de vacío, suministramos cada tornillo y sensor que necesitas.

Conclusión

Una línea de producción de bandejas de vino completa es un sistema complejo, pero la recompensa es un producto de alto valor en alta demanda. Dominando las etapas de Prensado en Caliente y Recorte, puedes dominar el mercado de embalaje premium.

¿Listo para construir tu fábrica? Deja que nuestros ingenieros diseñen un esquema que se adapte a tu espacio y presupuesto.