জাম্বিয়ান ক্লায়েন্ট সফলভাবে সম্পূর্ণ স্বয়ংক্রিয় ডিমের ট্রে প্রক্রিয়াকরণ কারখানা পরিচিত করিয়েছেন

আফ্রিকার বাজারে, হাঁস-মুরগির শিল্পের দ্রুত বৃদ্ধির কারণে পরিবেশবান্ধব কাগজের ডিমের কার্টনের চাহিদা অব্যাহত রয়েছে। জাম্বিয়ার একজন ক্লায়েন্ট, দীর্ঘদিন ধরে ডিমের প্যাকেজিং উৎপাদনে যুক্ত, আমাদের কোম্পানি থেকে একটি সম্পূর্ণ স্বয়ংক্রিয় ডিম ট্রে প্রক্রিয়াকরণ কারখানা কিনেছেন যাতে উৎপাদন ও পণ্যের মান উন্নত হয়।

কমিশনিংয়ের পরে, এই উৎপাদন লাইন উল্লেখযোগ্যভাবে দক্ষতা বৃদ্ধি করেছে, গ্রাহককে ম্যানুয়াল থেকে স্বয়ংক্রিয় প্রক্রিয়ায় রূপান্তর করতে সক্ষম করেছে। এটি কেবল শ্রম খরচ কমায় না, বরং পণ্যের ধারাবাহিকতা এবং বাজারে প্রতিযোগিতা শক্তি উল্লেখযোগ্যভাবে উন্নত করে।

গ্রাহকের পটভূমি এবং চাহিদার বিশ্লেষণ

জাম্বিয়ার কৃষি সম্পদ প্রচুর, যেখানে গবাদি পশু ও হাঁস-মুরগির খামার—বিশেষ করে ডিম দেওয়া হাঁস-মুরগির খামার—দেশব্যাপী বিস্তৃত। গ্রাহকের অঞ্চলে বর্জ্য কাগজের কাঁচামালের স্থিতিশীল সরবরাহ এবং ডিমের বাজারের বৃদ্ধি রয়েছে, যা কাগজের ডিমের কার্টনের জন্য শক্তিশালী চাহিদা চালিত করে।

পূর্বে ম্যানুয়াল ছাঁচের উপর নির্ভরশীল, গ্রাহকের উৎপাদন দক্ষতা কম, শুকানোর সময় দীর্ঘ এবং পণ্যের মোটা স্তর অনিয়মিত ছিল। অর্ডার বাড়ার সাথে সাথে, গ্রাহক জরুরি ভিত্তিতে একটি স্বয়ংক্রিয়, শক্তি-সাশ্রয়ী ডিম ট্রে প্রক্রিয়াকরণ কারখানা প্রয়োজন যাতে ব্যাপক উৎপাদন সম্ভব হয় এবং অপারেশনাল খরচ কমানো যায়।

আমাদের কাস্টমাইজড সমাধান

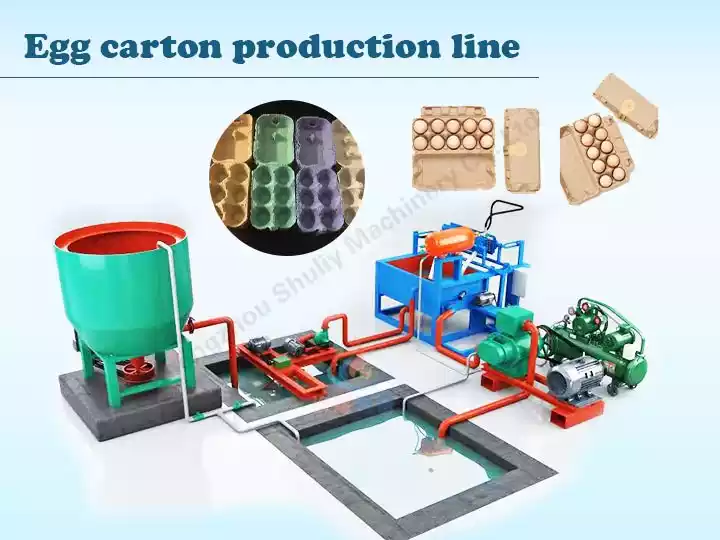

গ্রাহকের নির্দিষ্ট পরিস্থিতি এবং উৎপাদন লক্ষ্য অনুযায়ী, আমরা ৪×৪ ডিম ট্রে মেশিন কনফিগার করেছি যার আউটপুট ৪০০০-৫০০০ পিস/ঘণ্টা, সম্পূর্ণ স্বয়ংক্রিয় জাল বেল্ট শুকানোর ব্যবস্থা সহ। শুকানোর অংশে মাল্টি-লেয়ার সার্কুলেটিং গরম বাতাসের ডিজাইন রয়েছে যাতে সমান এবং দ্রুত শুকানো হয়।

সম্পূর্ণ উৎপাদন লাইনটি পল্প প্রস্তুতি থেকে শুরু করে শুকানো পর্যন্ত স্বয়ংক্রিয়ভাবে কাজ করে, যা ম্যানুয়াল শ্রম কমায়। জাম্বিয়ার বিদ্যুৎ পরিস্থিতি এবং পরিবহন লজিস্টিকস বিবেচনা করে, আমরা বিশেষভাবে সরঞ্জামের ভোল্টেজ, ড্রায়ার জ্বালানি ব্যবস্থা, এবং নিয়ন্ত্রণ পদ্ধতি সামঞ্জস্য করেছি যাতে ইনস্টলেশনের পর প্লাগ-অ্যান্ড-প্লে কার্যকারিতা নিশ্চিত হয়।

আমাদের ডিম ট্রে প্রক্রিয়াকরণ কারখানার প্রযুক্তিগত সুবিধা

আমাদের ডিম ট্রে উৎপাদন লাইন নিম্নলিখিত মূল সুবিধাগুলি প্রদান করে:

- কাস্টমাইজযোগ্য ছাঁচ: বিভিন্ন ডিমের ট্রে, ফলের ট্রে, কাপ ট্রে, এবং অন্যান্য পণ্যগুলির সাথে মানানসই

- অটোমেটেড নিয়ন্ত্রণ ব্যবস্থা: সহজ অপারেশন, শ্রম সাশ্রয়, এবং উন্নত উৎপাদন স্থিতিশীলতা

- উচ্চ-কার্যক্ষমতা শক্তি-সাশ্রয়ী শুকানোর ব্যবস্থা: গরম বাতাসের সঞ্চালন ডিজাইন দ্রুত শুকানোর জন্য নিশ্চিত করে কম শক্তি খরচে

- কাস্টমাইজযোগ্য ভোল্টেজ এবং প্লাগ মানক: বিভিন্ন দেশের শিল্প শক্তি সিস্টেমের সাথে মানানসই

- মজবুত এবং টেকসই নির্মাণ: মূল উপাদানগুলি স্টেইনলেস স্টীল এবং উচ্চ মানের কার্বন স্টীলের তৈরি, দীর্ঘ পরিষেবা জীবনের জন্য

আমাদের পরিষেবা এবং ডেলিভারি গ্যারান্টি

আপনার প্রকল্পের উৎপাদন এবং শিপিং পর্যায়ে, আমরা ব্যাপক পরিষেবা সমর্থন প্রদান করি। এর মধ্যে রয়েছে সরঞ্জাম পরীক্ষামূলক অপারেশন ভিডিও, প্যাকেজিং ছবি, এবং শিপমেন্টের আগে ভিডিও পরিদর্শন নিশ্চিতকরণ।

সমস্ত সরঞ্জাম জলরোধী ফিল্ম মোড়ানো এবং শক্তিশালী, মোটা কাঠের বাক্সে নিরাপদে প্যাকেজ করা হয়েছে যাতে দীর্ঘ দূরত্বের সমুদ্র পরিবহনে নিরাপদে পৌঁছানো যায়। গ্রাহকরা ভিডিও কলের মাধ্যমে সরঞ্জাম পরিচালনার অবস্থা দেখতে পারেন, নিশ্চিত করে আপনি সত্যিই যা দেখছেন তা পান।

গ্রাহকের প্রতিক্রিয়া এবং সহযোগিতার ফলাফল

সরঞ্জাম জাম্বিয়ায় পৌঁছানোর পর, আমাদের প্রযুক্তিগত দল রিমোট ভিডিও গাইডেন্স প্রদান করে গ্রাহককে ইনস্টলেশন এবং কমিশনিংয়ে সহায়তা করেছে। যন্ত্রপাতি সুচারুভাবে কাজ করে, উচ্চ গঠন নির্ভুলতা, সমান শুকানো, এবং উল্লেখযোগ্যভাবে উন্নত উৎপাদন দক্ষতা প্রদান করে।

গ্রাহক জানিয়েছেন যে কমিশনিংয়ের পর থেকে দৈনিক উৎপাদন পূর্বের তুলনায় তিনগুণের বেশি বেড়েছে, যা স্থানীয় বাজারে স্থিতিশীল সরবরাহ এবং প্রতিবেশী দেশে সম্প্রসারণের সুযোগ সৃষ্টি করেছে।