انڈے ٹرے مشین کو کیسے چلائیں؟

انڈہ ٹرے بنانے والی مشین کو صحیح طریقے سے چلانا موثر انڈہ ٹرے پیداوار کی بنیاد ہے۔ چاہے آپ ایک اسٹارٹ اپ کاروباری شخص ہوں یا ایک قائم شدہ پالپ مولڈنگ فیکٹری، صحیح آپریٹنگ عمل کو سمجھنا پیداوار کو بہتر بنا سکتا ہے، ناکامی کی شرح کو کم کر سکتا ہے، اور مشین کی عمر کو بڑھا سکتا ہے۔

اس رہنمائی میں، ہم آپ کو مرحلہ وار انڈہ ٹرے مشین کو چلانے کا طریقہ بتائیں گے، خام مواد کی تیاری سے لے کر مکمل ٹرے اسٹیکنگ تک، تاکہ آپ مستحکم، موثر اور منافع بخش پیداوار حاصل کر سکیں۔

خام مواد اور پالپنگ سسٹم تیار کریں

انڈہ ٹرے بنانے والی مشین شروع کرنے سے پہلے، پہلا قدم پالپ تیار کرنا ہے۔

کچا مواد

- فضول کاغذ

- پرانے کارٹن

- اخبارنامہ

- دفتر کا کاغذ

- کتابیں

یہ مواد بھگو کر ریشے کے مکسچر میں تبدیل کیا جاتا ہے۔

پالپنگ کا عمل

- ضائع کاغذ کو کترنے والے میں ڈالیں۔

- پانی ڈالیں تاکہ پالپ کا مکسچر تیار ہو جائے۔

- پالپ کی کنسٹریشن کو ایڈجسٹ کریں (عام طور پر 1–2%)۔

- شفافیت کے لیے آلودگی کو فلٹر کریں۔

ایک مستحکم پالپنگ سسٹم یکساں ریشے کی تقسیم کو یقینی بناتا ہے، جو براہ راست انڈہ ٹرے کی طاقت اور سطح کے معیار کو متاثر کرتا ہے۔

انڈہ ٹرے مشین کا مولڈ فارمنگ آپریشن

یہ انڈہ ٹرے مشین کے بنیادی آپریٹنگ مرحلے ہیں۔

تشکیل کا عمل

- مولڈ میں پالپ کے مکسچر میں ڈوبنا۔

- ویکیوم سکشن ریشے کو سانچے کی سطح پر جذب کرتا ہے۔

- گیلی انڈہ ٹرے خود بخود تشکیل پاتی ہے۔

اہم آپریٹنگ ٹپس:

- مستحکم ویکیوم پریشر کو برقرار رکھیں۔

- مکسچر ٹینک کی سطح کی مستقل مزاجی کو یقینی بنائیں۔

- سانچے کی سطح کو صاف رکھیں تاکہ ٹرے کی تشکیل ہموار ہو۔

خودکار منتقلی اور ڈیمولڈنگ سسٹم

تشکیل کے بعد، گیلی انڈہ ٹرے کو منتقلی کے سانچے میں منتقل کیا جاتا ہے۔

- ویکیوم تشکیل کے سانچے سے منتقلی کے سانچے کی طرف منتقل ہوتا ہے۔

- انڈہ ٹرے بغیر نقصان کے آسانی سے جدا ہو جاتے ہیں۔

- خودکار اسٹیکنگ شروع ہوتی ہے۔

یہ خودکار منتقلی یقینی بناتی ہے:

- تیز پیداوار کی رفتار

- یکساں ٹرے کی شکل

- کم محنت کی ضرورت

انڈہ ٹرے پیداوار لائن کی خشک کرنے کا عمل

خشک کرنا انڈہ ٹرے کی طاقت اور ظاہری شکل کے لیے ایک اہم مرحلہ ہے۔

خشک کرنے کے آپشنز

- قدرتی خشک کرنا (کم سرمایہ کاری، موسمی حالات پر منحصر)

- اینٹ بھٹی خشک کرنے والی لائن

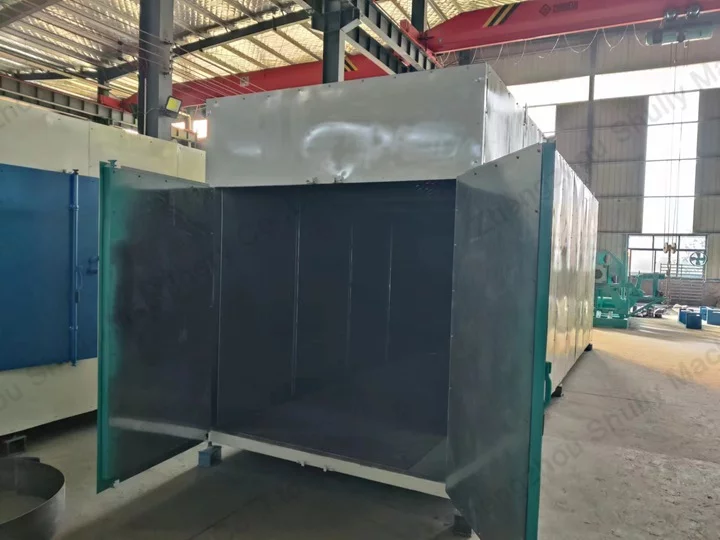

- میٹل ملٹی لیئر ڈرائر

- گرم ہوا گردش خشک کرنے کا سرنگ

خشک کرنے کا درجہ حرارت کنٹرول

- تجویز کردہ خشک کرنے کا درجہ حرارت: 120–180°C

- مستحکم ہوا کا بہاؤ یکساں خشک کرنے کو یقینی بناتا ہے

موثر خشک کرنا ٹرے کی سختی اور اسٹوریج کی استحکام کو بہتر بناتا ہے۔

گرم پریس اور اسٹیکنگ (اختیاری)

پریمیم انڈہ ٹرے کے لیے، ایک گرم پریس سسٹم شامل کیا جا سکتا ہے:

- ہموار سطح

- یکساں موٹائی

- بہتر ظاہری شکل

- زیادہ اسٹیکنگ استحکام

مکمل ٹرے پھر اسٹیک اور پیک کی جاتی ہیں۔

ہمارے انڈہ ٹرے مشین کو کیوں منتخب کریں؟

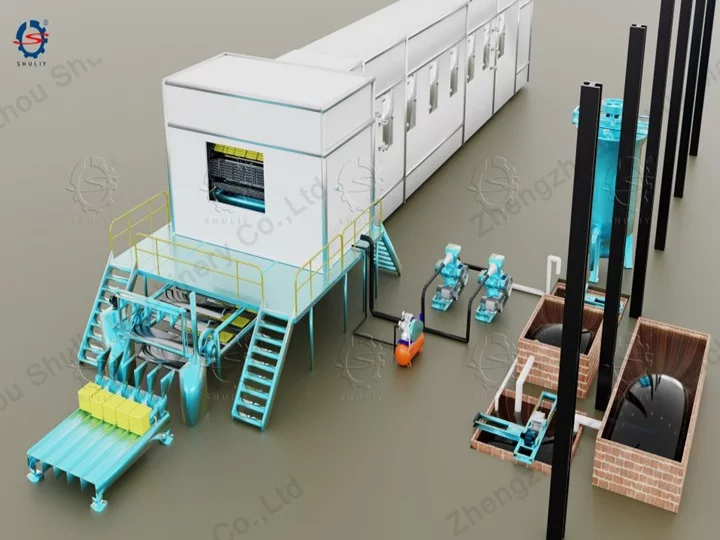

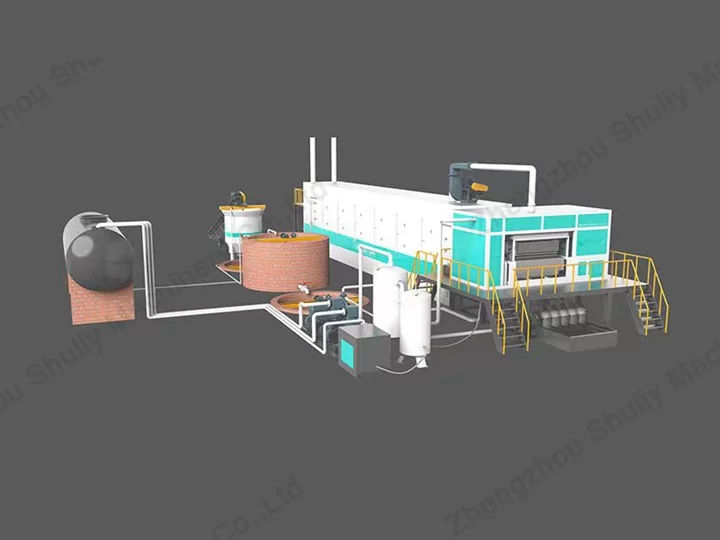

ہمارا خودکار انڈہ ٹرے مشین اعلیٰ کارکردگی، مستحکم، اور لاگت مؤثر انڈہ کارٹن پیداوار کے لیے ڈیزائن کی گئی ہے۔

- 1000 سے 8000 ٹکڑے فی گھنٹہ کی اعلیٰ پیداوار کی صلاحیت

- مکمل خودکار پی ایل سی کنٹرول سسٹم

- پائیدار سانچے جن کی خدمت کی عمر لمبی ہے

- توانائی بچانے والے خشک کرنے کے حل

- مکمل ٹرنکی انڈہ ٹرے پیداوار لائن کا ڈیزائن

ہم مکمل حل فراہم کرتے ہیں: پالپنگ → مولڈنگ → خشک کرنا → اسٹیکنگ → پیکنگ۔

اپنا انڈہ ٹرے پیداوار کاروبار شروع کرنے کے لیے تیار ہیں؟ آج ہی ہم سے رابطہ کریں!

اگر آپ ایک اعلیٰ کارکردگی والا انڈہ ٹرے مشین چاہتے ہیں جس کی قیمت فیکٹری سے براہ راست ہو، تو ہمارے انجینئر آپ کے:

- ضروری پیداوار

- دستیاب ورکشاپ کی جگہ

- مقامی توانائی کی لاگت

- بجٹ پلان

ابھی ہم سے رابطہ کریں مفت لے آؤٹ ڈیزائن تازہ ترین اقتباس مشین ویڈیوز کے لیے!