उच्च-गुणवत्ता पल्प अंडा ट्रे कैसे पहचानें?

When you invest in an egg tray production line, your ultimate goal is to create a product that wins the market and satisfies your customers. A high-quality egg tray doesn’t just protect eggs; it’s a silent ambassador for your brand’s commitment to excellence. But what exactly defines a “high-quality” product?

Simply “not being broken” is far from enough. As industry experts, we’ve identified 5 key indicators for judging the quality of molded fiber packaging. Understanding these metrics will not only help you evaluate your own products but also highlight how crucial superior production equipment is to achieving these high standards.

Appearance and feel

This is what your customers see and touch first, forming their initial perception of your product’s value.

Color and cleanliness: ek uchitquality paper pulp tray ki rang saman aur lagatar hona chahiye. Surface साफ होना चाहिए, किसी भी साफ dark spots, grease stains, ya unsightly pulp clumps नहीं होने चाहिए।

This standard requires that in the pulping system, the raw materials are thoroughly broken down and impurities are effectively filtered out.

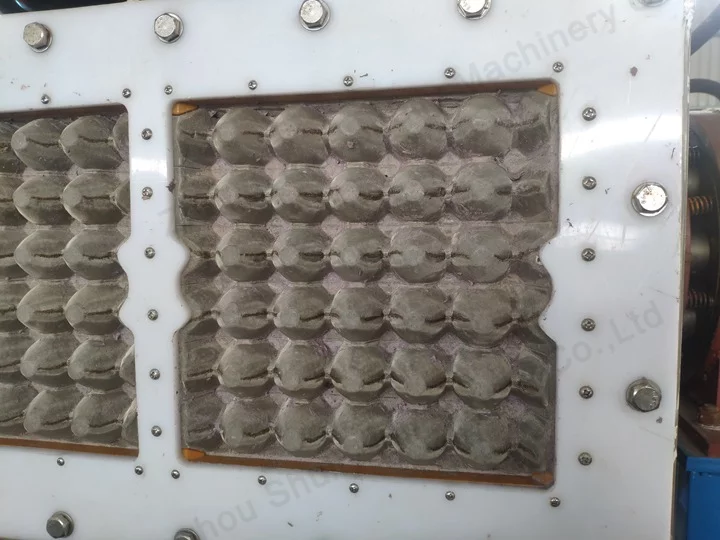

Surface texture: jab aap apna haath surface par chalate hain, to achhi tray ko lagbhag smooth aur even mehsoos hona chahiye, khaaskar hot pressing ke baad. Ek rough, fuzzy texture aam taur par molding ya drying process ke dauran samasyaon ka sanket hota hai.

Odor: utpaad me koi ajeeb ya musty smells nahi hone chahiyen, jo ki clean raw materials ki kami ya damp environment me storage ki galti ka sanket ho sakta hai.

Structural strength and resilience

This is the most critical function of an egg tray—its ability to protect. We evaluate this based on two key metrics that are central to egg tray quality standards: stiffness and resilience.

The egg tray strength test: place the tray on a flat surface and gently press down on its top cones. A quality tray will exhibit good support and resist collapsing or deforming. This directly relates to its load-bearing capacity during stacking and transportation.

Resilience test: gently bend the edge of the tray. A well-made product will have a degree of flexibility and should spring back to its original shape, rather than breaking or forming a permanent crease. This means it can absorb shock and impact.

Expert Tip: Shrestha majbooti aur lachilapan uniform pulp mixture aur molding system ki powerful vacuum suction se janm lete hain, jo lagatar motai aur ghaleez structure ko sunischit karte hain. ye egg trays ki quality sudharne ka mukhya hissa hai.

Weight and uniformity

So, what makes a good quality paper egg tray from a professional buyer’s perspective? Consistency. This internal metric directly reflects the stability of your production process.

Individual weight: randomly select several trays and weigh them. Their weights should be nearly identical. Consistent weight indicates stable pulp concentration in your production line.

Thickness uniformity: hold a tray up to a light source. The light passing through should be relatively even. If some areas are noticeably thinner, these are weak points prone to breakage. This is one way to identify defects in pulp molding.

Expert tip: uchch samuchitata hasil karna asambhav hai jab tak sthir, precision-engineered egg tray molding machine na ho.

Dryness and moisture resistance

Moisture is the nemesis of all paper products. A tray that looks good but isn’t fully dry is a hidden quality risk.

Judging dryness: tray ko poori tarah sookha hona chahiye aur kamre ke temperature par hona chahiye, kisi bhi nami ya thand ki jhalak ke bina. Ek aisa utpaad jo prabhavi drying system se thoroughly dry nahi hua hai, uski majbooti kafi kam ho jayegi aur mold lagne ki sambhaavna adhik hogi.

Moisture resistance: surface par kuch boondon ko girakar dekhiye. Ek quality tray par boonde surface par thodi der tak tikti hain bina tezi se absorb hue.

Edges and details

The details often separate the amateur from the professional. A product’s finishing touches speak volumes about the manufacturer’s standards.

Edge trim: ek quality tray ke kinare saaf aur smooth hone chahiye, bina extra fuzzy material ya “flashing” ke. Ye polished look aam taur par hot press machine se paida hota hai.

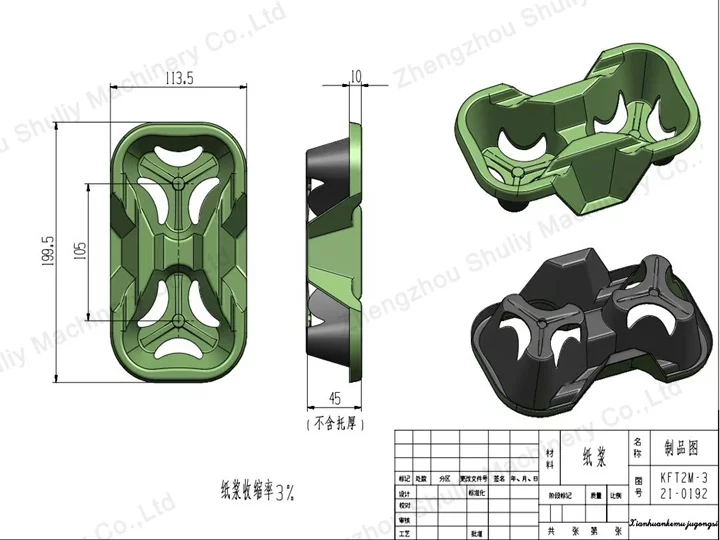

Logo clarity: agar aapke molds me brand logo ya anya markings hain, final product par imprint sharp, clear, aur well-defined hona chahiye.

निष्कर्ष

In summary, the benchmark for pulp molded products quality is a perfect combination of appearance, strength, consistency, and durability. Achieving this requires a well-designed and stable production line. From clean pulping and uniform molding to thorough drying, every stage is critical.

Understanding the direct relationship between the egg tray machine and product quality is fundamental. Investing in a professional production line is an investment in the cornerstone of your product’s quality and the surest way to earn customer trust and stand out in a competitive market.

Want to learn how our equipment can help you produce premium egg trays that meet all these quality standards? Contact our technical experts today for a professional solution!