ডিমের ট্রে মোল্ডিং যন্ত্রের কার্যপ্রণালী এবং সাধারণ সমস্যা সমাধানের গাইড

পাল্প মোল্ডিং এবং প্যাকেজিং শিল্পে, ডিম ট্রে মোল্ডিং মেশিন হল বর্জ্য পাল্পকে পুনর্ব্যবহারযোগ্য এবং পরিবেশবান্ধব ডিম ট্রেতে রূপান্তর করার জন্য মূল যন্ত্রপাতি। এর কাজের নীতি এবং সাধারণ ব্যর্থতা বোঝা কেবল উৎপাদন দক্ষতা উন্নত করতে সহায়তা করে না বরং যন্ত্রপাতির জীবনকালও বাড়ায়।

ডিম ট্রে মোল্ডিং মেশিনের কাজের নীতি

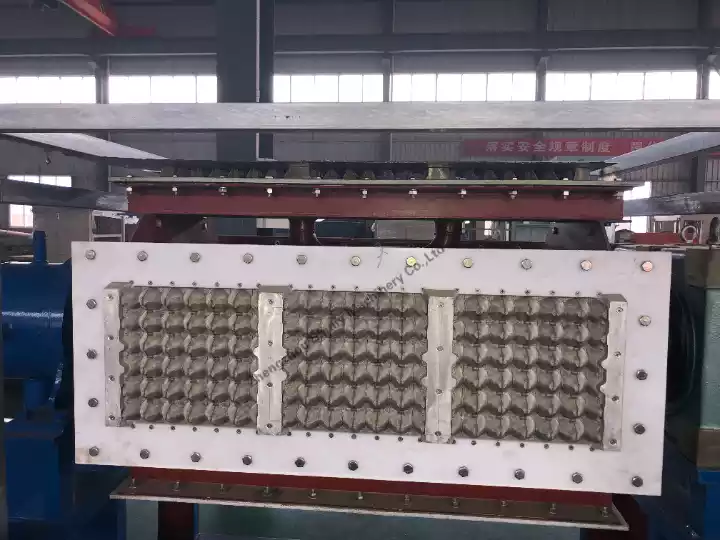

৪০০০-৭০০০pcs/h ডিম ট্রে মেশিনকে উদাহরণ হিসেবে নিয়ে, মেশিনের কার্যক্রম নিম্নলিখিত পদক্ষেপগুলিতে বিভক্ত।

পাল্প প্রস্তুতি

বর্জ্য কাগজ জল দিয়ে মেশানো হয় এবং একটি পাল্পারে সমজাতীয় পাল্পে পরিণত হয় এবং অশুদ্ধতার জন্য ছাঁকনি করা হয়।

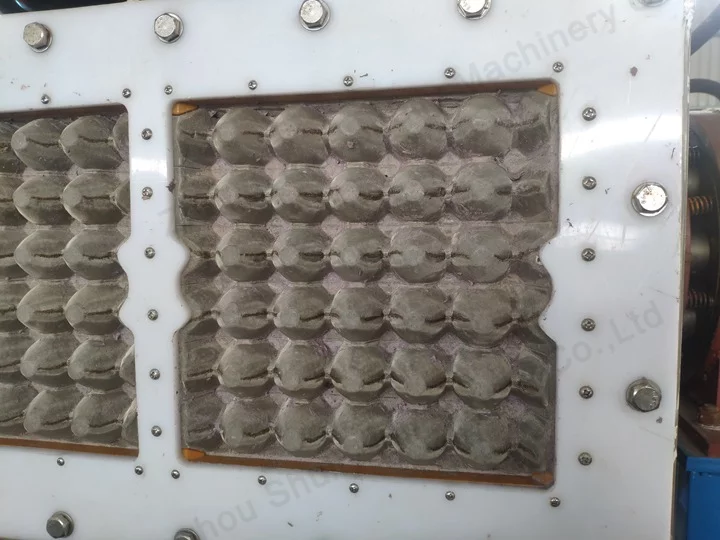

মোল্ড শোষণ এবং গঠন

গঠন মোল্ড পাল্পকে ভ্যাকুয়াম সিস্টেমের মাধ্যমে শোষণ করে একটি ভিজা ডিম ট্রের আকার তৈরি করে।

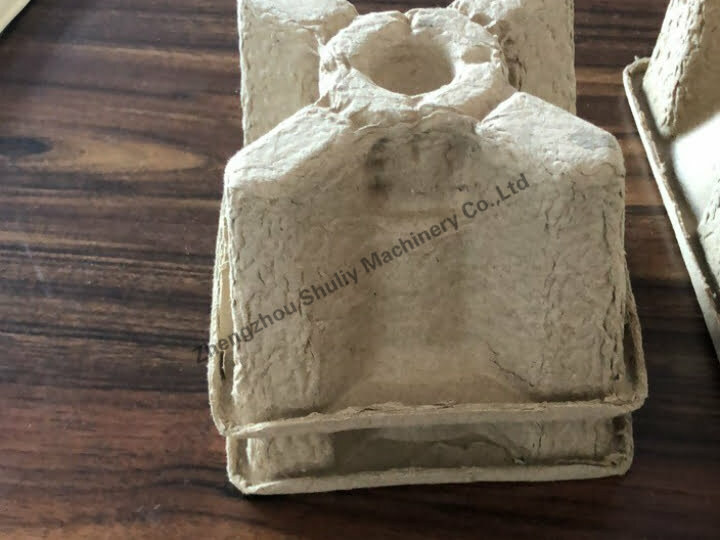

স্থানান্তর এবং ডিমোল্ডিং

মোল্ডটি ঘোরায় এবং ভিজা ডিম ট্রেকে স্থানান্তর মোল্ডে স্থানান্তর করে প্রাথমিক গঠন সম্পন্ন করে।

শুকানো

ভিজা ডিম ট্রে একটি শুকানোর সিস্টেম দ্বারা প্রক্রিয়া করা হয় অতিরিক্ত আর্দ্রতা অপসারণ করতে শক্তি এবং স্থিরতা নিশ্চিত করতে।

সাধারণ ত্রুটি এবং সমস্যা সমাধানের পদ্ধতি

অস্বাভাবিক পাল্প ঘনত্ব

ফেনোমেনন:

ডিম ট্রে গঠনের পর সহজেই ভেঙে যায় বা অসম অনুপাত থাকে।

কারণ:

ভুল উপাদানের অনুপাত।

অপর্যাপ্ত বা খুব দীর্ঘ মিশ্রণ সময়।

সমাধান:

পাল্পের ঘনত্বকে সুপারিশকৃত মানে সামঞ্জস্য করুন। সাধারণত 2%-4%।

মিশ্রণ যন্ত্রপাতির কার্যক্রমের অবস্থা নিয়মিত পরীক্ষা করুন।

দুর্বল মোল্ড শোষণ

ফেনোমেনন:

অপূর্ণ গঠন বা ডিম ট্রের খসখসে পৃষ্ঠ।

কারণ:

ভ্যাকুয়াম শোষণ সিস্টেমের অপর্যাপ্ত চাপ।

অবরুদ্ধ বা ক্ষতিগ্রস্ত ছাঁচ।

সমাধান:

ভ্যাকুয়াম পাম্পের কাজের অবস্থান পরীক্ষা করুন, এবং ছাঁচের পৃষ্ঠ পরিষ্কার করুন।

গুরুতর পরিধানে থাকা ছাঁচটি প্রতিস্থাপন করুন।

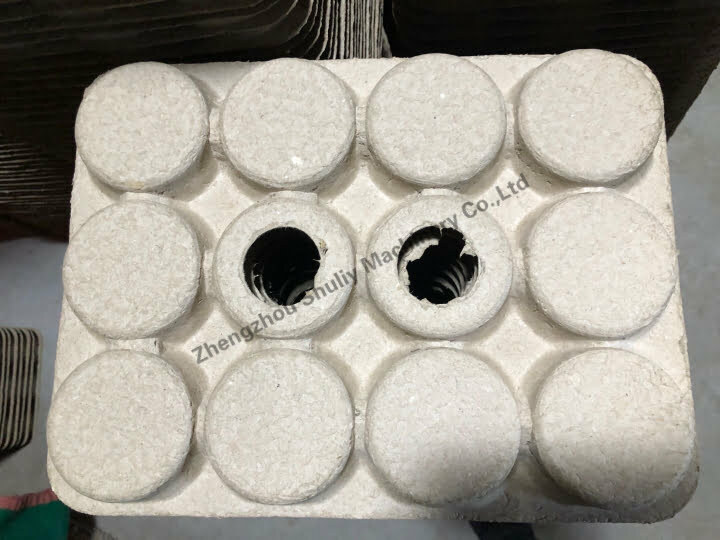

দুর্বল শুকানোর প্রভাব

ফেনোমেনন:

ডিম ট্রে ফাটল বা সম্পূর্ণভাবে শুকায়নি।

কারণ:

শুকানোর চেম্বারের তাপমাত্রা খুব কম বা অসম।

অপর্যাপ্ত শুকানোর সময়।

সমাধান:

সাধারণত ১৫০°C – ২০০°C এর মধ্যে চেম্বার তাপমাত্রা সামঞ্জস্য করুন।

শুকানোর সময় বাড়ান বা গরম বাতাসের সিস্টেম পরীক্ষা করুন।

সংক্রমণ সিস্টেমের ব্যর্থতা

ফেনোমেনন:

ডিম ট্রে মসৃণভাবে স্থানান্তর হয় না।

কারণ:

মোড়ানো বা ক্ষতিগ্রস্ত স্থানান্তর বেল্ট

মোটরের ব্যর্থতা।

সমাধান:

স্থানান্তর বেল্ট পরিষ্কার করুন এবং মোটরের কার্যক্রমের অবস্থা পরীক্ষা করুন।

ক্ষতিগ্রস্ত স্থানান্তর বেল্ট বা মোটর প্রতিস্থাপন করুন।

ব্যবহার এবং রক্ষণাবেক্ষণের জন্য সুপারিশসমূহ

- মোল্ড নিয়মিত পরিষ্কার করুন যাতে পাল্পের অবশিষ্টাংশ গঠন সঠিকতায় প্রভাব না ফেলে।

- প্রতিটি সপ্তাহে ভ্যাকুয়াম সিস্টেম এবং এয়ার পাম্পের সিলিং পরীক্ষা করুন।

- নিয়মিতভাবে স্থানান্তর চেইন এবং বিয়ারিংগুলিতে লুব্রিকেন্ট যোগ করুন।

- দীর্ঘ সময়ের জন্য বন্ধ করার আগে পাল্প ট্যাংক খালি করুন এবং যন্ত্রপাতি ধোয়া।

উপসংহার

ডিম ট্রে মোল্ডিং মেশিনের কাজের প্রবাহ এবং সাধারণ সমস্যা সম্পর্কে পরিচিত হয়ে, আপনি উৎপাদন প্রক্রিয়ায় ডাউনটাইম এবং রক্ষণাবেক্ষণ খরচ কমাতে পারেন।

আমাদের শুলী 4000-7000pcs/h ডিম ট্রে মোল্ডিং মেশিন উচ্চ উৎপাদন চাহিদার জন্য গ্রাহকদের জন্য একটি স্থিতিশীল এবং কার্যকর পছন্দ।