Was ist das Funktionsprinzip einer Apfelkorbformmaschine?

Die Herstellung von Apfelkisten wird immer beliebter, da Obstexporteure und Verpackungsfabriken nach umweltfreundlichen, stoßdämpfenden Lösungen suchen. Die Apfelkisten-Formmaschine funktioniert ähnlich wie eine Eierkartonmaschine—der einzige große Unterschied liegt in der Form der Formen.

Dieser Artikel erklärt den vollständigen Produktionsablauf, von der Pulpe bis zum Formen, damit Käufer verstehen, wie eine Apfelkisten-Formmaschine funktioniert, bevor sie investieren.

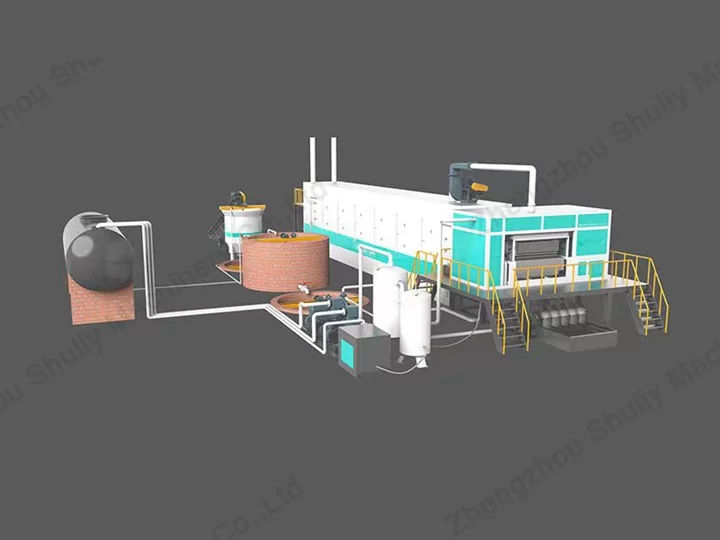

Rohstoffvorbereitung

Die Produktion beginnt im Pulpsystem, wo Rohstoffe wie:

- Altpapier

- Alte Wellpappkartons (OCC)

- Zeitung

- Papierreste

werden im Pulpmaschine mit Wasser vermischt.

Wie es funktioniert

Der Pulper zerdrückt und rührt die Papierfasern, bis sie eine einheitliche Suspension bilden. Die Einstellung der Pulpkonzentration ist entscheidend, da sie die endgültige Dicke und Festigkeit der Apfelkiste direkt beeinflusst.

Der Ausgang ist eine glatte, gleichmäßige Pulpe, die bereit zum Formen ist.

Pulpeinstellung und Lagerung

Nach dem Pulpvorgang fließt die Mischung in einen Homogenisierungstank, in dem Zusätze wie:

- Wasserabweisende Mittel

- Versteifungsmittel

können je nach Produktanforderungen hinzugefügt werden.

Der Pulpe wird dann in einen Lagerbehälter gepumpt, um eine kontinuierliche Zuführung zur Formmaschine zu gewährleisten. Die Pulpe stabil zu halten, sichert eine gleichmäßige Kistenqualität.

Apfelkisten-Formmaschine

Dies ist der wichtigste Schritt. Die Apfelkisten-Formmaschine verwendet Vakuumsaugformtechnik, das gleiche Prinzip wie bei der Eierkartonproduktion.

Schritt-für-Schritt-Formprozess:

- Die Formform wird in den Pulptank eingetaucht.

- Vakuumdruck zieht die Papierfasern auf die Formoberfläche.

- Überschüssiges Wasser wird sofort durch das Vakuumsystem entfernt.

- Ein feuchter Apfelkisten wird genau nach den Hohlräumen der Form geformt.

Der einzige echte Unterschied zur Eierkartonproduktion ist die Form—Apfelkisten benötigen tiefere, rundere Hohlräume, die speziell dafür ausgelegt sind, Früchte sicher zu halten.

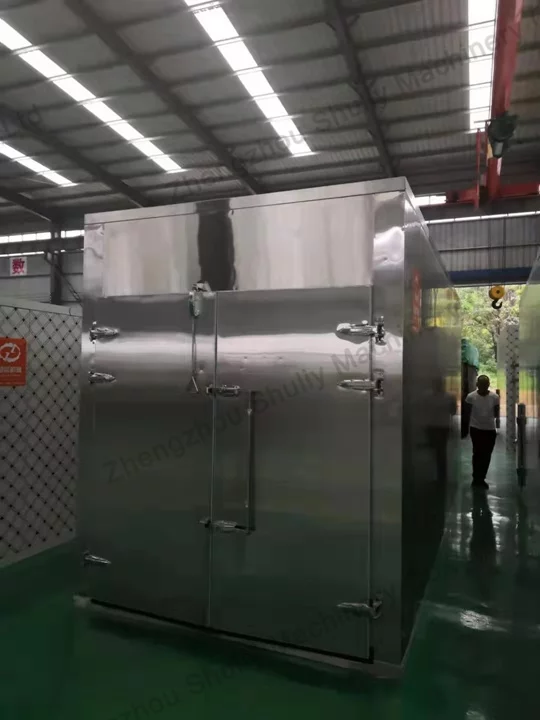

Trocknungsabschnitt

Nach dem Formen müssen die feuchten Apfelkisten getrocknet werden. Je nach Fabrikgröße können Kunden wählen:

- Metall-Trocknungsanlage (Brennstoff, Gas, Diesel)

- Backstein-Trocknungsraum

- Natürliche Sonnentrocknung (für kostengünstige kleine Projekte)

Die automatisierte Trocknungsanlage ist die stabilste Option, da sie schnelles, sauberes und gleichmäßiges Trocknen gewährleistet.

Heißpressen

Nach dem Trocknen können die Kisten optional durch eine Heißpressmaschine geführt werden.

Vorteile des Heißpressens:

- Glattere Oberfläche

- Genauere Form

- Höhere Festigkeit

- Bessere Stapel- und Transportbeständigkeit

Für hochwertige Exportobstverpackungen wird das Heißpressen sehr empfohlen.

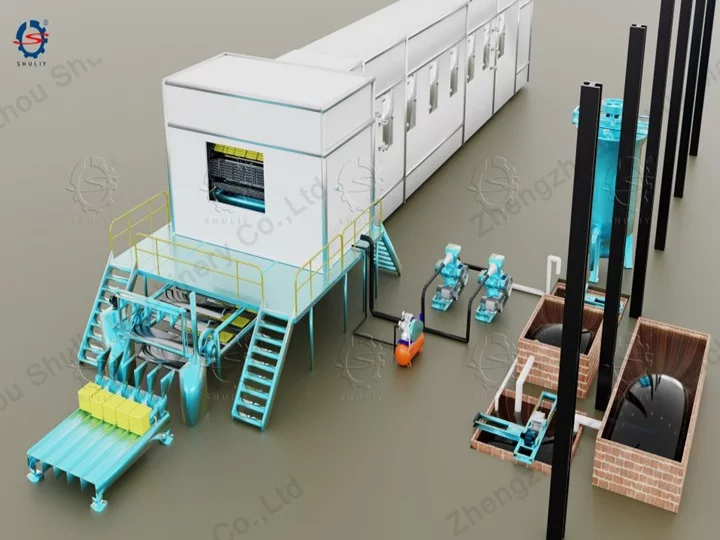

Endmontage und Verpackung

Die fertigen Kisten werden automatisch:

- Gestapelt

- Gezählt

- Verpackt

und für die Lieferung vorbereitet.

Dies schafft einen vollständig automatisierten Arbeitsablauf, bei dem die Apfelkisten-Formmaschine mit minimalem Personal arbeitet—typischerweise 1–3 Arbeiter können eine komplette Linie bedienen.

Warum bevorzugen Apfelkistenhersteller diese Produktionslinie?

- Umweltfreundliche geformte Zellstoffverpackung

- Niedrige Rohstoffkosten

- Hochwertige Anwendung im Obstverpackungs- und Exportmarkt

- Ähnliche Technologie wie Eierkartonmaschinen—leicht zu erlernen und zu warten

- Flexible Formanpassung: Apfelkisten, Birnenkisten, Mangokisten usw.

Für Obstproduzenten, Verpackungsfabriken und landwirtschaftliche Exporteure ist die Investition in eine Apfelkisten-Formmaschine eine profitable und nachhaltige Entscheidung.

Eine moderne und effiziente Methode zur Herstellung von Apfelkisten

Mit einfachen Rohstoffen, stabilem Output und hoher Automatisierung bietet die Apfelkisten-Formmaschine eine zuverlässige Lösung für die Herstellung langlebiger geformter Zellstoff-Obstkisten. Ob Sie Ihr Verpackungsgeschäft erweitern oder eine neue umweltfreundliche Produktlinie starten, diese Maschine bietet Effizienz und gleichbleibende Qualität.

Wenn Sie den vollständigen Produktionsplan, Maschinenangebot, Formenanpassung oder Layout-Design wünschen, kontaktieren Sie uns noch heute. Wir empfehlen die beste Apfelkisten-Produktionslinie entsprechend Ihrem Budget und Ihrer Kapazität.